Understanding Lifting Loops

Lifting loops are an essential component in the construction and manufacturing industries, playing a pivotal role in the safe and efficient handling of heavy loads. These robust devices are designed to provide a secure and reliable connection point for lifting, transporting, and positioning heavy materials and equipment. Whether you're working in precast concrete, steel fabrication, or any domain requiring heavy load management, lifting loops offer unparalleled convenience and safety.

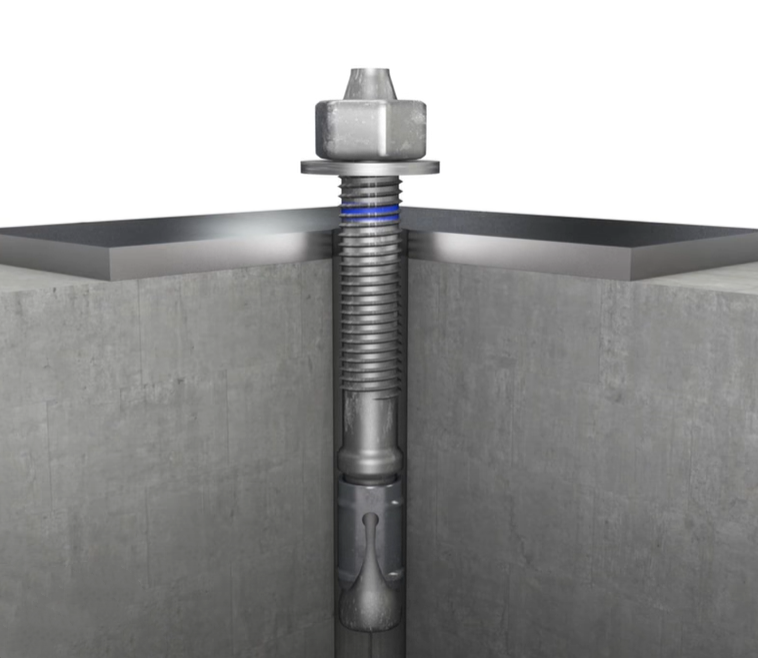

The term "lifting loops" encompasses a range of products with varying designs and applications. These loops are often constructed from high-strength materials that can withstand significant forces while maintaining durability over time. When properly installed, lifting loops help ensure that loads are transported safely without compromising structural integrity.

Applications of Lifting Loops in Construction

In construction projects, lifting loops are commonly used during precast concrete installations. This is where "cast in loop" systems often come into play. Cast in loops are designed to be embedded within concrete structures during fabrication, providing a built-in anchoring point for lifting and positioning during assembly. These loops are not only functional but also essential for reducing risks and enhancing efficiency on-site.

Another frequently used type is the "transport loop." Transport loops serve a similar purpose but are specifically designed for moving loads from one location to another. They offer flexibility during transportation and can be temporary, easy-to-remove fixtures. Transport loops are ideal for modular construction projects, machinery setup, or projects where materials need to be repositioned multiple times.

Key Benefits of Using Lifting Loops

There are many reasons why lifting loops are favored across industries. One primary benefit is their ability to ensure safety during heavy lifting operations. The secure connection they provide reduces the likelihood of accidents, protecting both workers and materials. Furthermore, lifting loops are highly versatile, as they can be tailored to specific project requirements, including weight capacity, size, and material.

Another advantage is their efficiency. Using lifting loops during construction or manufacturing processes minimizes delays, as these components simplify the logistics of handling and positioning heavy items. This efficiency translates into cost savings and quicker project turnaround times.

Choosing the Right Lifting Loop for Your Project

Selecting the right lifting loop involves assessing the project's specific needs. Factors to consider include load weight, type of material, and the intended lifting method. Whether you require permanent cast in loops or temporary transport loops, it's important to choose a product that aligns with your project's safety standards and operational requirements.

Enhancing project safety and performance is no small task, and lifting loops play an integral role in achieving these goals. Their sturdy design, adaptability, and ability to handle heavy loads make them indispensable in many industrial scenarios.