Custom CNC Machining Service: Why Early Decisions Shape Final Part Quality

In custom CNC machining, most problems do not originate on the shop floor.

They originate before machining begins.

By the time a cutter touches material, many outcomes are already locked in—tolerance interaction, distortion risk, inspection complexity, even delivery stability. This is why experienced buyers evaluate a custom CNC machining service not by machine lists, but by how it handles decisions upstream.

Custom Machining Starts Long Before Programming

A drawing may look complete, yet still leave critical questions unanswered.

Which surfaces control assembly?

Which dimensions must remain stable across batches?

Which tolerances matter functionally, and which are cosmetic?

A capable custom CNC machining service treats drawings as starting assumptions, not final instructions. Early-stage review often reveals hidden conflicts that would otherwise surface as scrap or rework weeks later.

This front-loaded thinking shifts risk out of production and into planning—where it is far cheaper to manage.

Where Projects Lose Control Without Realizing It

Many CNC projects appear successful at first.

Samples are approved. Initial batches pass inspection. Then variation creeps in.

Common warning signs include:

-

minor dimensional drift that stays “within tolerance”

-

increasing adjustment required during assembly

-

surface finish inconsistency affecting mating parts

-

corrective actions that fix symptoms, not causes

These issues point to missing process discipline, not machining error.

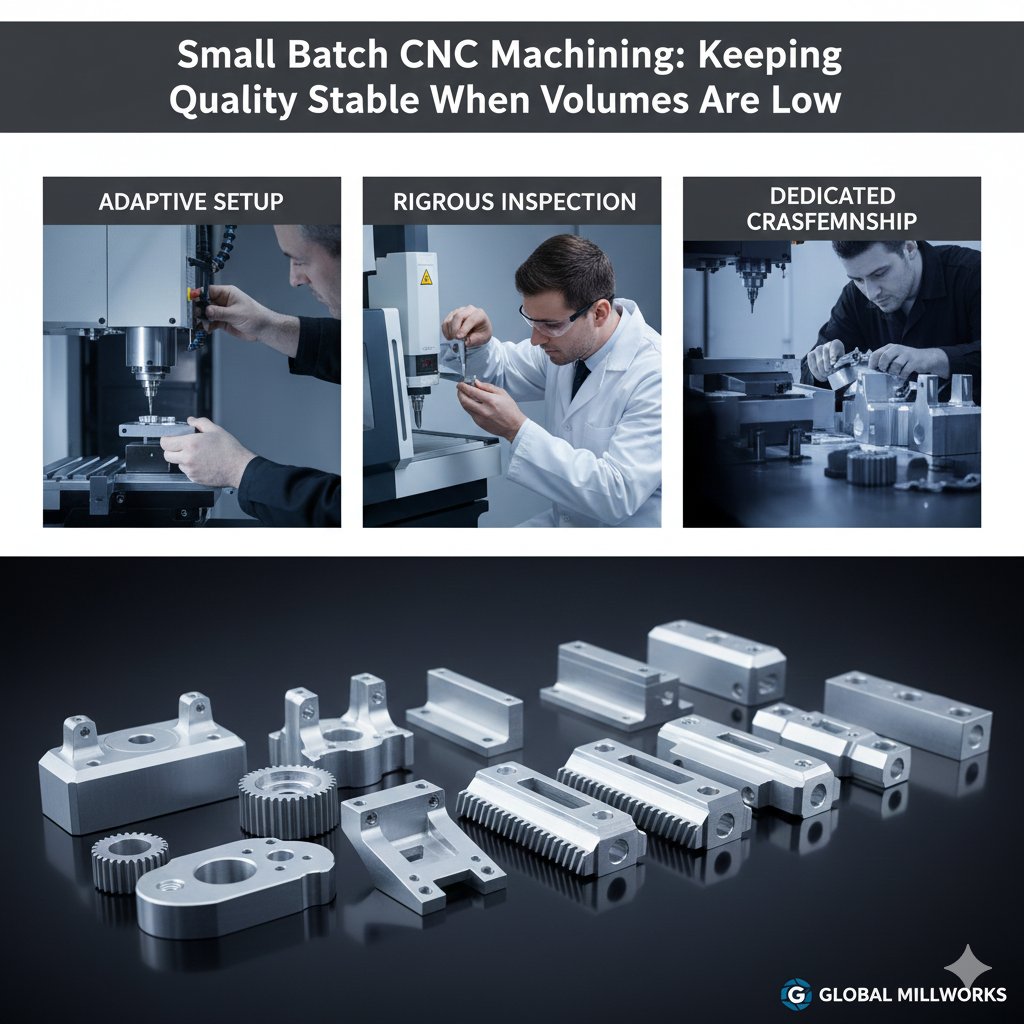

Why Fixturing Strategy Often Matters More Than Toolpaths

Toolpaths can be optimized quickly.

Fixturing cannot.

In custom CNC machining, fixture design defines how consistently a part is located relative to the machine. Poor fixturing introduces variation that no amount of programming refinement can eliminate.

Effective fixturing strategies consider:

| Fixturing factor | Impact on part quality |

|---|---|

| Repeatable datum reference | Controls positional accuracy |

| Clamping force distribution | Prevents deformation |

| Fixture wear monitoring | Maintains batch stability |

| Ease of setup verification | Reduces operator variation |

Suppliers who invest in fixture validation reduce variation at its source rather than compensating downstream.

Material Variability Is a Hidden Risk Multiplier

Material certificates confirm grade, not behavior.

Two bars of the same alloy can machine very differently.

Residual stress, hardness variation, and heat treatment condition all influence how a part behaves once material is removed. Without compensating strategies, distortion appears after machining—often during inspection or assembly.

An experienced custom CNC machining service adapts machining order and stock removal strategy to material behavior, not just nominal specifications.

Inspection Strategy Shapes What Problems You Actually See

Inspection does not just detect issues.

It determines which issues are visible.

Final inspection alone often misses process drift until it becomes severe. In-process checks, by contrast, expose trends early enough to correct them.

| Inspection approach | What it reveals |

|---|---|

| Final inspection only | End-result compliance |

| In-process measurement | Process stability |

| SPC trend analysis | Early drift detection |

| First-off verification | Setup accuracy |

Projects that rely solely on final inspection usually pay more for corrections later.

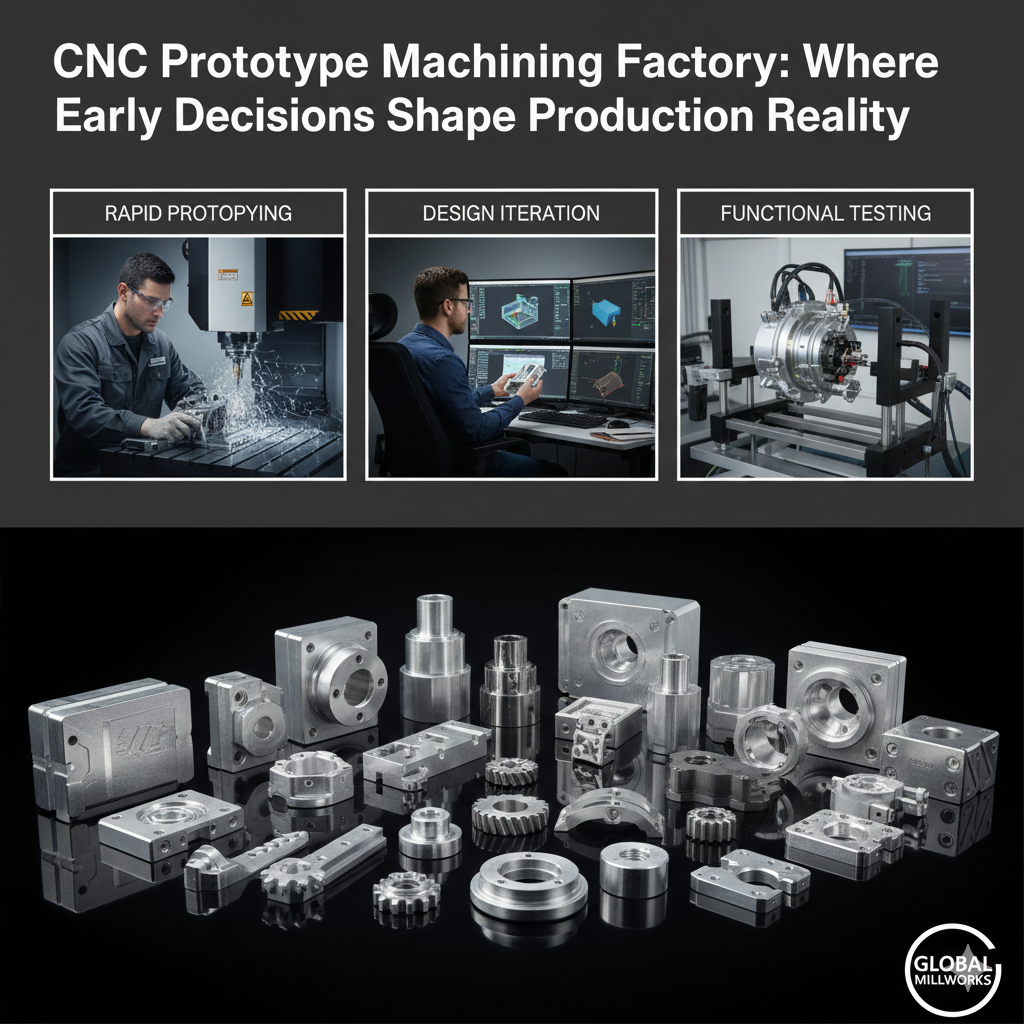

Scaling from Prototype to Production Is the Real Test

Prototypes confirm feasibility.

Production confirms control.

The transition between the two is where many custom CNC machining services struggle. Tool wear, operator changes, and scheduling pressure expose weaknesses that were invisible at low volume.

Suppliers prepared for scale design processes that tolerate variation without losing control.

Manufacturers such as Jingle approach custom machining with batch stability as a design objective, not an afterthought, reducing risk when programs grow.

Lead Time Stability Comes from Preparation, Not Speed

Fast machining does not guarantee fast delivery.

Stable lead times depend on material readiness, fixture availability, program validation, and capacity buffering. Skipping preparation may shorten the first delivery but often extends the second.

For buyers managing production schedules, predictability outweighs aggressive promises.

Where Custom CNC Machining Services Create Real Value

Beyond making parts, a strong custom CNC machining service contributes by:

-

identifying tolerance conflicts early

-

recommending manufacturable geometry adjustments

-

stabilizing production output over time

-

supporting design changes without disrupting supply

These contributions rarely appear on quotations, yet they dominate total project cost and risk.

Custom CNC Machining Across Industrial Applications

Custom machining supports diverse sectors:

| Sector | Typical application |

|---|---|

| Construction hardware | Structural connectors |

| Industrial equipment | Mounts and frames |

| Energy systems | Interface components |

| Automotive supply | Brackets and housings |

| Automation | Alignment-critical parts |

Across all sectors, the common expectation is not novelty, but consistency under real conditions.

Conclusion: Custom Means Planned, Not Reactive

Custom CNC machining succeeds when uncertainty is addressed early, not chased later. Suppliers who manage process decisions upfront deliver parts that assemble smoothly, scale reliably, and support long-term supply programs.

Those who do not shift risk downstream—where it is far more expensive to resolve.

To explore custom machining capabilities and related industrial components, visit the Jingle home page or reach out via the contact page for project-specific discussions and documentation support.