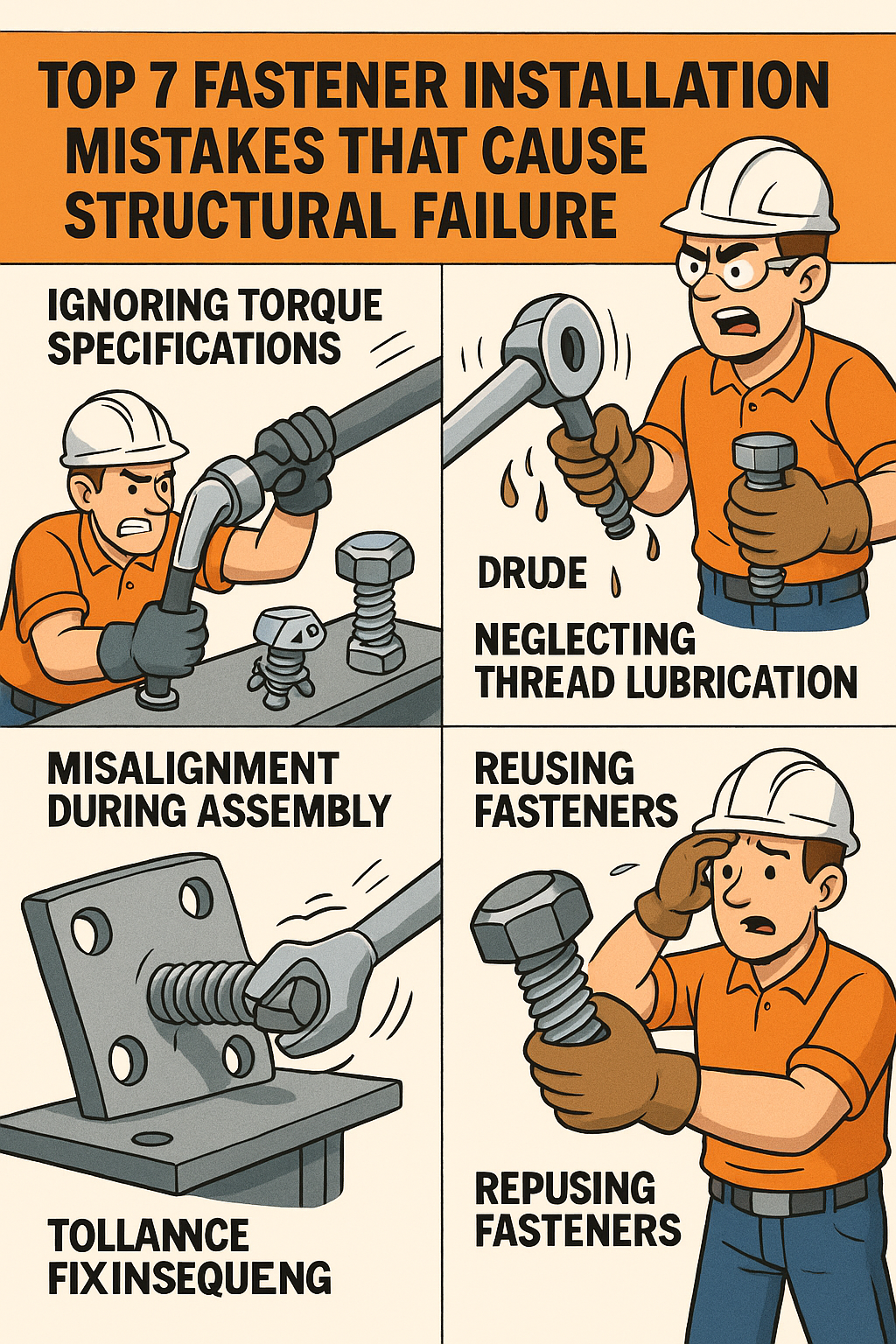

Top 7 Fastener Installation Mistakes That Cause Structural Failure

Why Perfect Fasteners Still Fail on Site

Fasteners are small, but their failure can bring entire structures down.

Bridges, cranes, and industrial machinery rely on bolts, nuts, and anchors to transfer enormous loads.

Yet even when made from high-grade steel, improper installation can destroy their intended strength.

Research from the American Institute of Steel Construction (AISC) shows that over 70% of bolt-related failures stem from installation issues—not design or material defects.

Jingle’s engineers have seen the same pattern: the problem isn’t the fastener—it’s how it’s installed.

1. Ignoring Torque Specifications

Torque defines how tightly a bolt clamps two surfaces together.

Too little torque leads to joint slippage, while excessive torque stretches the bolt beyond its yield point.

Proper installation requires:

-

Using calibrated torque wrenches or hydraulic tensioners.

-

Considering friction coefficients—a dry thread vs. lubricated one can change torque values by up to 40%.

-

Re-torque checks after thermal cycles or vibration exposure.

At Jingle, all fastening systems include recommended torque charts aligned with ISO 898-1 and ASTM F606 standards.

2. Neglecting Thread Lubrication

Friction determines whether torque becomes clamping force or wasted energy.

Without lubrication, metal-on-metal contact causes galling and uneven tension distribution.

Lubricants such as molybdenum disulfide or zinc-based pastes can:

-

Reduce friction variability.

-

Prevent thread seizing under high load.

-

Improve preload accuracy and repeatability.

Jingle applies controlled lubrication on critical threads during pre-assembly to maintain consistent friction factors.

3. Misalignment During Assembly

When bolt holes are off-center or plates are slightly warped, the fastener bends under load.

This introduces shear stress, leading to fatigue cracks and permanent deformation.

Preventive Measures

-

Always align parts using temporary positioning pins.

-

Avoid forcing bolts into misaligned holes.

-

Inspect tolerance fit before tightening.

Precision-machined components from Jingle are manufactured within ±0.02 mm tolerance to ensure perfect alignment in multi-point assemblies.

4. Reusing Fasteners Beyond Design Life

Bolts may look fine after disassembly, but microscopic stretching changes their stress capacity.

Reusing critical fasteners—especially grade 8.8 or 10.9 bolts—can reduce load-bearing capacity by 20–30%.

Best practice:

-

Replace all load-bearing bolts after each major maintenance cycle.

-

Label fasteners for one-time or multi-use categories.

-

Store replacement kits in sealed, humidity-controlled environments.

Jingle supplies all structural fasteners with traceability codes and usage recommendations to avoid accidental reuse.

5. Overlooking Surface Cleanliness

Even a thin layer of oil, rust, or debris can prevent the joint surfaces from fully contacting,

creating false preload that relaxes under vibration.

Before tightening:

-

Clean surfaces with solvent or mild abrasive pads.

-

Check for rust, paint overspray, or embedded grit.

-

For outdoor use, apply anti-corrosion coatings after assembly.

Jingle’s galvanized and coated fasteners resist contamination and ensure stable clamping over time.

6. Inconsistent Tightening Sequence

Fasteners in flanges or plates must be tightened in sequence to distribute load evenly.

Improper tightening order leads to warping or localized stress.

Correct Approach

-

Use a cross-pattern or star-pattern tightening sequence.

-

Gradually increase torque in multiple passes (e.g., 30% → 60% → 100%).

-

Verify uniform torque using calibrated equipment.

Jingle’s assembly manuals provide torque-sequence diagrams tailored for structural and machinery applications.

7. Skipping Post-Installation Inspection

Final inspection is the last defense against long-term failure.

Missing washers, under-tightened bolts, or damaged threads often go unnoticed until vibration or load exposes the weakness.

Recommended checks include:

-

Visual inspection for alignment and corrosion.

-

Torque verification with digital readouts.

-

Ultrasonic tension testing for critical assemblies.

Jingle offers optional in-situ inspection kits and maintenance documentation to ensure every connection remains safe and reliable.

Ensuring Structural Reliability Through Installation Discipline

Even the best-engineered fasteners can’t perform if installation practices fall short.

Precision, cleanliness, torque, and inspection are as vital as metallurgy and coating.

With Jingle’s precision hardware and quality control support, every joint achieves the balance of strength, repeatability, and safety demanded by modern construction and manufacturing.

To explore Jingle’s complete range of industrial fastening systems and installation support services, visit our homepage or connect with our team through the contact page.