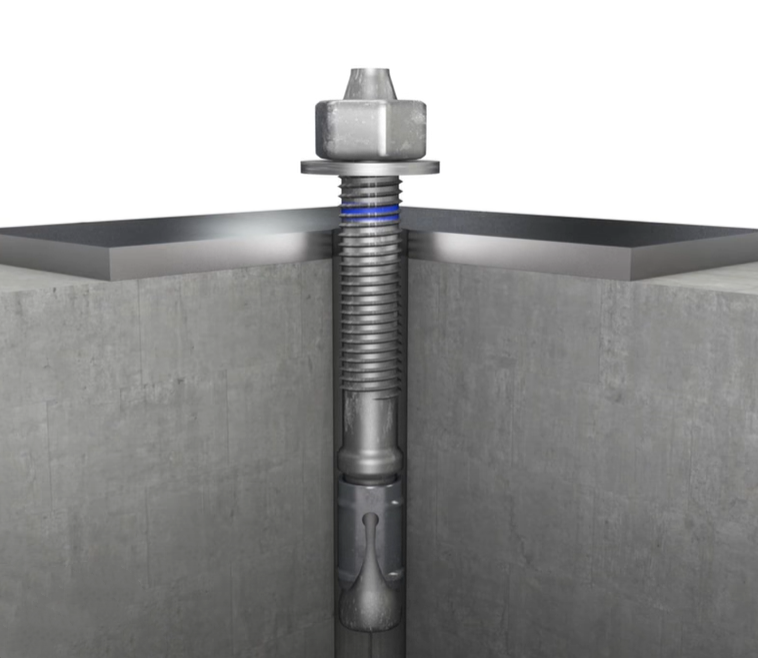

Understanding the Challenge of Stripped Bolts

Treatment of stripped bolts can be a frustrating experience, especially when it hinders the progress of the project. Whether you are working in a car, a piece of furniture or any machine, you have to know how to remove the bolts. When the bolt is stripped, its head will lose the grip required to rotate the tool. This is usually due to excessive force applied during tightening or loosening, or due to corrosion over time.

Basic Techniques for Cancel Bolts

One of the first methods to consider is to use rubber bands. For bolts that do not have severe corrosion, place the rubber band on the head of the peeling head and slowly rotate the screwdriver or wrench to provide the required grip. If that doesn't work, investing in a bolt extractor kit can be beneficial. These are specially designed tools that grab peeling bolt heads and can provide the necessary torque for extraction. Also, if you can get into the drill bit, drill carefully into the center of the bolt, sometimes loosening the keys between the bolt and screwing into the material.

Advanced Solutions for Removing Bolts

A more advanced approach may be required for severe damage or stuck due to rust or corrosion. Apply penetration oil freely around the bolt and let it sit for several hours or overnight. This can help break down rust and simplify the removal process. Heat can also be applied using a lighter or heat gun; expanding material around the bolt can sometimes help release its grip strength. When using heat, it is crucial to exercise caution to avoid damaging the surrounding material.

All in all, understanding how to effectively eliminate stripped bolts involves using the right tools and techniques. Whether using rubber band straps or more complex solutions involving heat, preparation and patience are key to successfully removing stubborn bolts.