Balancing Cost and Performance: A Buyer’s Guide to Galvanized Precast Accessories

Cost-Performance Balance in Infrastructure Construction

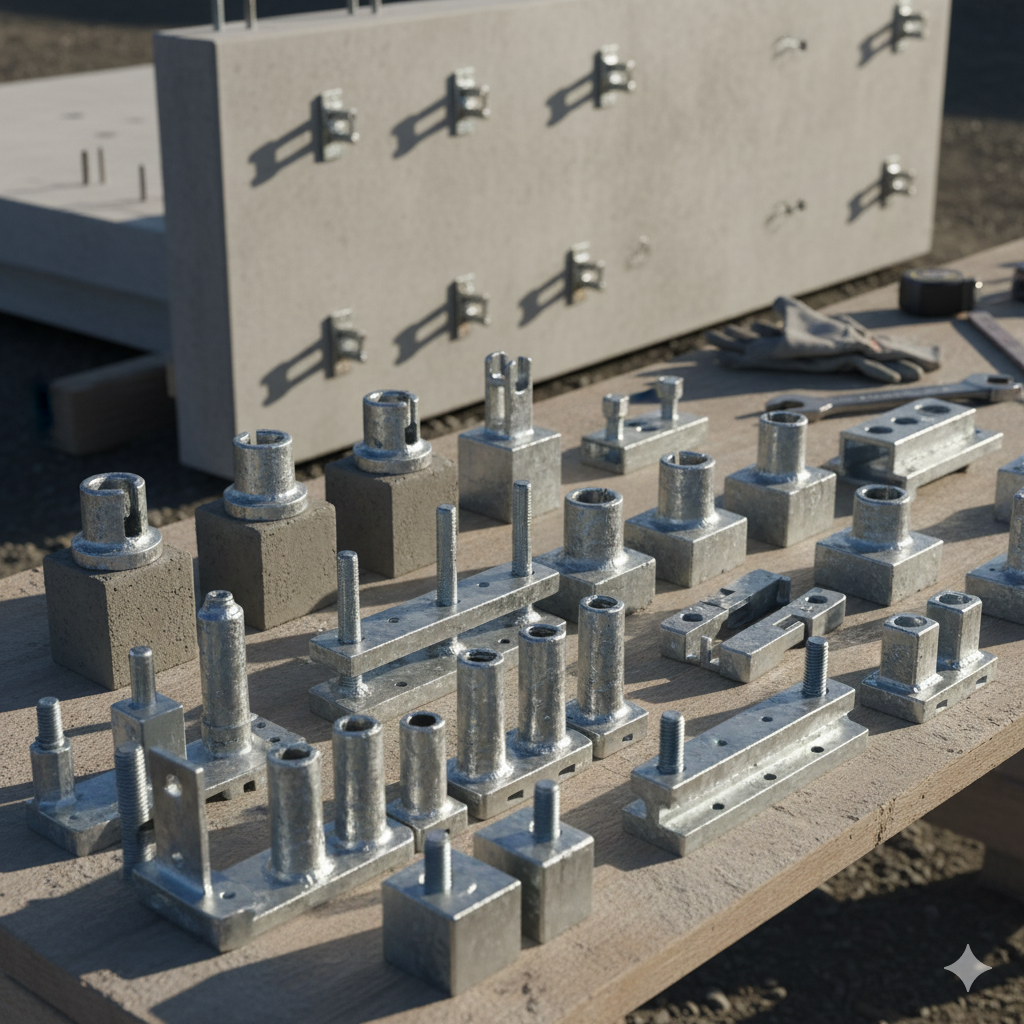

In large-scale infrastructure, the choice of precast accessories extends far beyond the immediate purchase price. While contractors often focus on unit cost, performance factors such as corrosion resistance, load capacity, and compliance with international standards ultimately determine lifecycle efficiency.

According to World Bank infrastructure data, over 30% of cost overruns in public projects are linked to materials that fail prematurely or require excessive maintenance. Galvanized precast accessories, when properly specified, reduce such risks by delivering long-term value through extended durability.

Understanding Galvanization: Why It Matters for Precast Components

Galvanization is not a uniform process; the method used directly impacts both cost and performance:

-

Hot-Dip Galvanization

-

Provides thick, uniform zinc coating.

-

Lifespan: 50–100 years depending on environment (AGA).

-

-

Electro-Galvanization

-

Thinner coating, more economical.

-

Suitable for indoor or low-exposure environments.

-

-

Duplex Coating (Galvanization + Paint/Epoxy)

-

Combines galvanization with additional barrier layers.

-

Ideal for coastal, industrial, or highly corrosive conditions.

-

Selecting the right method ensures that accessories meet both budgetary and performance requirements of a project.

Material Options and Performance Trade-Offs

Beyond coatings, the base material of precast accessories determines strength, fatigue resistance, and cost.

| Material | Typical Applications | Cost Factor | Performance Notes |

|---|---|---|---|

| Mild Steel + Galvanization | Standard anchors, inserts | Low to moderate | Balanced cost, good general durability |

| Stainless Steel | Coastal bridges, metro tunnels | High | Exceptional corrosion resistance, high initial cost |

| Alloy Steel | Heavy-load viaducts, industrial facilities | Moderate to high | High tensile strength, extended fatigue life |

OEM suppliers like Jingle offer flexible customization, aligning the choice of material and coating with specific structural requirements and budget frameworks.

Balancing Procurement Priorities

When evaluating galvanized precast accessories, procurement decisions often weigh four critical dimensions:

-

Initial Cost: price per unit, tooling, and coating expenses.

-

Lifecycle Cost: expected service life, replacement intervals, and maintenance.

-

Compliance: adherence to ISO, ASTM, EN, and local construction codes.

-

Logistics: delivery schedules, packaging standards, and international documentation.

Balancing these factors prevents overspending on unnecessary specifications while ensuring that critical safety and durability requirements are met.

Application Examples in Different Environments

-

Highway Bridges – Hot-dip galvanized anchor plates distribute traffic loads and resist weathering.

-

Underground Rail Systems – Stainless steel couplers prevent degradation in constant moisture.

-

Coastal Facilities – Duplex-coated lifting systems maintain strength in salt-rich air.

-

Urban Towers – Galvanized threaded inserts accelerate wall panel installation with reliability.

-

Industrial Plants – Heavy-duty connectors stabilize precast frames under vibration.

These scenarios illustrate how different environments demand different balances of cost efficiency and performance durability.

Q&A: Practical Considerations

Q1: What certifications are essential for reliable precast accessories?

A: ISO 9001 quality management, EN 1090 compliance for structural steel, and ASTM standards for coating thickness are key benchmarks.

Q2: How does galvanization affect total lifecycle cost?

A: While hot-dip galvanization has a higher upfront cost, it extends accessory lifespan by decades, lowering the total cost of ownership.

Q3: Can customized accessories remain cost-competitive?

A: Yes. By optimizing dimensions, load ratings, and material use, OEM manufacturers like Jingle ensure custom parts align with both technical and financial goals.

Q4: How is consistency managed in large orders?

A: Automated CNC machining and batch traceability systems maintain dimensional accuracy and coating uniformity across thousands of units.

Q5: What delivery terms support global projects?

A: Trade terms such as FOB, CIF, and DDP allow flexibility. Jingle provides full export documentation and logistics support.

Why Jingle Aligns Cost With Performance

Balancing cost and performance in precast infrastructure is not about choosing the cheapest option, but about aligning specifications with long-term project requirements.

At Jingle, we provide:

-

OEM/ODM customization for galvanized precast accessories.

-

ISO-certified quality control with inspection reports for every batch.

-

Flexible material and coating options tailored to diverse environments.

-

Proven global export capability with efficient lead times.

Learn more about our full product range on the homepage or contact page.