Powertrain Systems Under Extreme Stress

From urban traffic to heavy-duty hauling, powertrains endure constant torque, heat, and vibration. Any inaccuracy in gears, shafts, or housings can multiply into fuel inefficiency, excess emissions, or sudden breakdowns. CNC machining offers the precision needed to handle loads exceeding hundreds of Newton-meters, while maintaining dimensional accuracy that ensures smoother transmission and longer component life.

For global OEM manufacturers, sourcing CNC parts is no longer optional—it is the foundation of performance and compliance in modern automotive engineering.

Engineering Precision That Sustains Performance

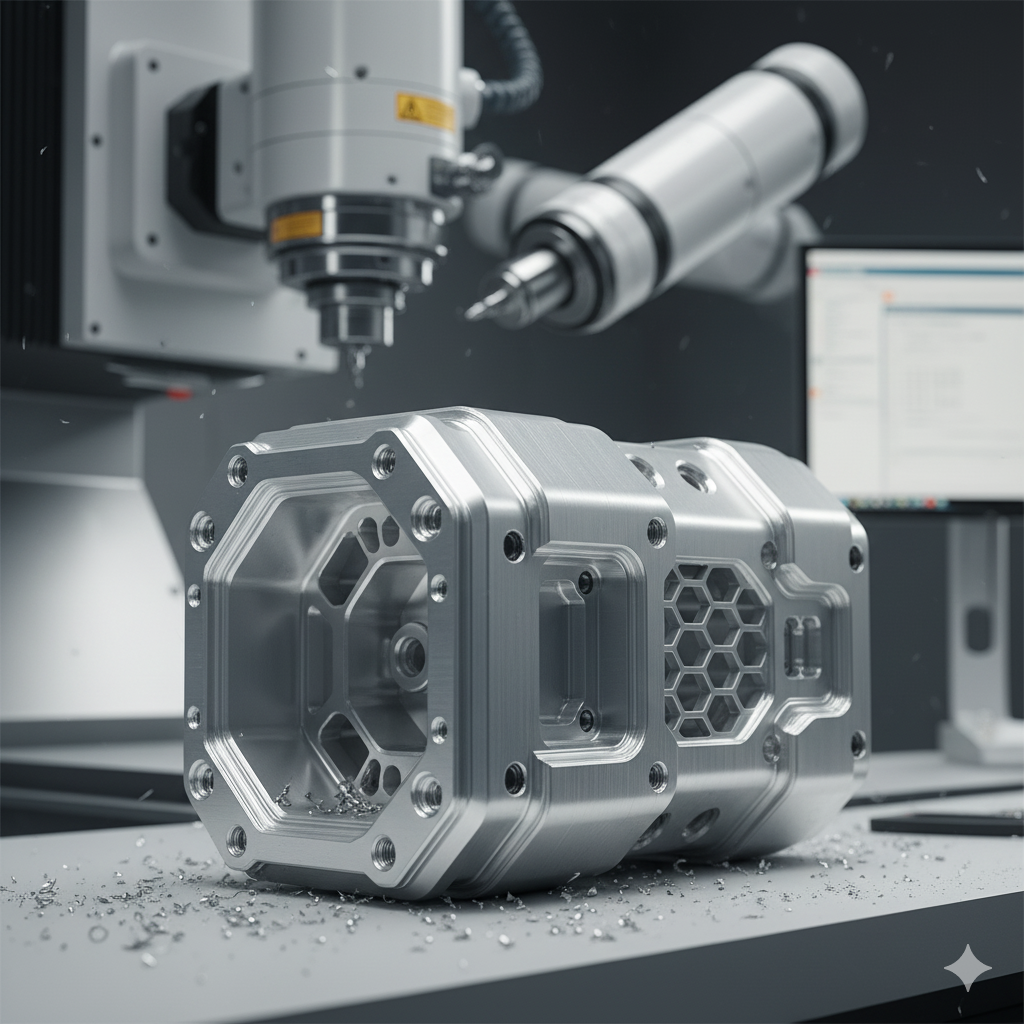

CNC machining enables powertrain parts to be produced with repeatable tolerances that directly improve efficiency:

-

Gear sets and shafts – machined to micrometer-level precision for quiet and efficient torque delivery.

-

Transmission housings – durable components engineered to withstand pressure and vibration.

-

Bearing carriers and brackets – optimized for alignment, reducing wear over time.

-

Engine timing components – CNC-cut sprockets and pulleys ensuring synchronization under thermal stress.

-

Custom OEM fittings – tailored to integrate seamlessly with hybrid and electric powertrains.

Performance Comparison: Conventional vs. CNC Machined Powertrain Parts

| Parameter | Conventional Parts | CNC Machined OEM Parts (JINGLE) |

|---|---|---|

| Tolerance Accuracy | ±0.2 mm | ±0.01 mm |

| Thermal Endurance | Moderate | Optimized for high heat cycles |

| Vibration Resistance | Limited | Engineered for high RPM loads |

| Lifecycle Durability | 50,000 km average | 100,000+ km with consistency |

| OEM Custom Adaptability | Low | Fully scalable for EV/Hybrid |

Application Scenarios Across the Automotive Industry

The demand for OEM CNC parts spans traditional vehicles and next-generation platforms:

-

Passenger cars – smoother gear transitions reduce energy loss and noise.

-

Heavy-duty trucks – CNC-engineered shafts and housings handle long-haul strain.

-

Hybrid vehicles – custom components integrate electrical modules with combustion engines.

-

Electric vehicles (EVs) – CNC parts designed for compact, high-RPM e-motors.

-

Motorsports – lightweight, high-strength CNC components withstand extreme acceleration and braking.

Each of these scenarios proves one point: without CNC precision, powertrain performance cannot meet modern expectations.

JINGLE’s OEM Factory Edge

JINGLE combines factory-scale CNC production with OEM customization to meet the diverse needs of automotive powertrains:

-

Prototype-to-production expertise for new drivetrain designs.

-

Material versatility including hardened steels, aluminum alloys, and titanium.

-

Batch reliability with CNC-controlled quality checks at every stage.

-

Compliance certifications aligned with international automotive standards (ISO/TS16949).

-

Future-ready solutions supporting hybrid and electric transitions.

By blending precision machining with scalable production, JINGLE helps automotive OEMs achieve consistent results across global supply chains.

Industry Questions Answered

Q1: How do CNC parts improve powertrain efficiency?

By ensuring tighter tolerances, CNC parts reduce energy losses caused by misalignment or friction.

Q2: Can CNC machining meet the lightweight demands of EV powertrains?

Yes. Materials such as aluminum-magnesium alloys combine strength with weight reduction.

Q3: Are CNC parts scalable for both passenger vehicles and heavy-duty applications?

Absolutely. JINGLE supports small-batch prototypes and high-volume OEM supply with equal precision.

Q4: What makes OEM CNC parts more cost-effective in the long term?

They extend lifecycle durability, reduce warranty claims, and improve fuel or battery efficiency.

Precision Under Load, Reliability on the Road

Automotive powertrains are no place for compromise. CNC machining delivers the precision and durability required to survive extreme loads, high RPM cycles, and thermal stress.

For manufacturers, CNC parts are not just components—they are strategic enablers of efficiency, compliance, and long-term reliability.

Discover JINGLE’s OEM CNC machining solutions for automotive powertrains on the homepage or reach our team directly via the contact page.