Securing the Future: Custom Industrial Fasteners for Next-Generation Manufacturing

The Foundation of Every Reliable Structure

Every machine, bridge, or production system begins with a simple principle—secure connections. Industrial fasteners are often overlooked, yet their performance defines the reliability and safety of entire assemblies.

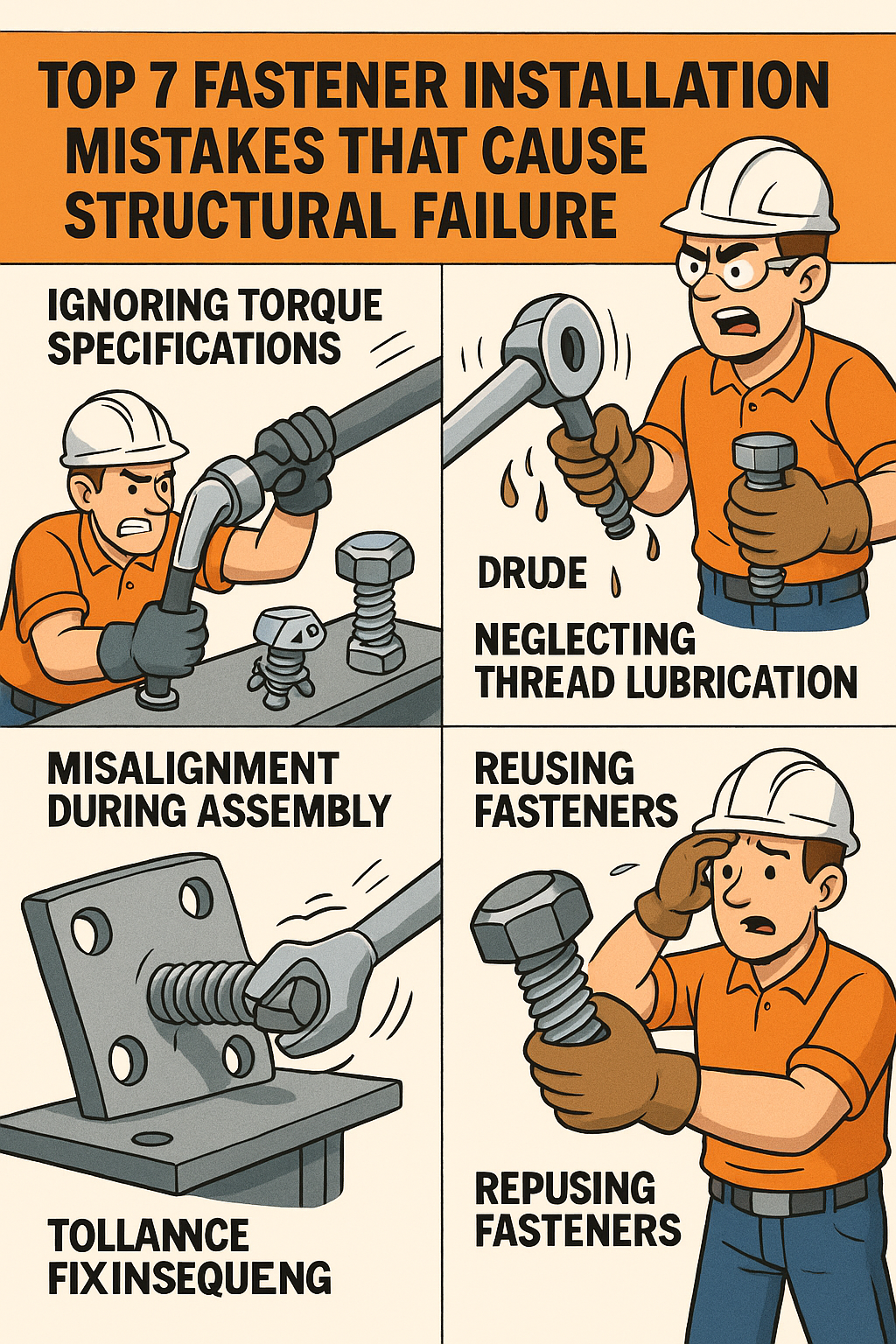

However, mass-produced fasteners rarely meet the specific mechanical and environmental demands of modern applications. When vibration, heat, and pressure vary across industries, standardized bolts or screws often fail to maintain tension or resist corrosion.

Custom industrial fasteners resolve these challenges through OEM-level precision, engineered materials, and geometry optimization that align with each project’s technical specifications.

Engineering Precision in Fastener Design

Custom fasteners go beyond shape and thread—they are engineered systems designed to handle stress, load distribution, and long-term fatigue.

Key design elements include:

-

Thread Geometry Optimization: Ensures even stress distribution under torque and shear forces.

-

Material Selection Algorithms: Match mechanical loads with tensile, yield, and fatigue limits.

-

Surface Coating Engineering: Enhances resistance against oxidation, chemicals, or marine corrosion.

-

Precision Heat Treatment: Balances hardness and elasticity for vibration-heavy environments.

At Jingle, OEM fastener production combines these principles within automated CNC systems, achieving micron-level consistency for global supply chains.

Standard vs. OEM Custom Fasteners

| Attribute | Standard Fasteners | Custom Industrial Fasteners |

|---|---|---|

| Tolerance | ±0.3 mm | ±0.05 mm (CNC calibrated) |

| Material Range | Carbon steel / zinc-plated | Alloy steel, stainless, titanium, brass |

| Corrosion Protection | Basic plating | Galvanized, anodized, ceramic, powder-coated |

| Load Testing | Random batch | 100% digital torque and tensile validation |

| Design Compatibility | Generic | Fully tailored to OEM product geometry |

With this level of control, fasteners move from commodity hardware to engineered performance components.

Core Advantages: Engineering Value in Every Thread

1. Predictable Structural Behavior

Custom torque-tension calibration ensures load distribution remains uniform, improving connection stability under cyclic stress.

2. Longevity in Harsh Environments

Jingle’s coating systems provide 5–10× higher corrosion resistance in marine, chemical, or high-humidity environments.

3. Precision at Scale

Automated CNC threading and optical inspection eliminate deviation across mass-produced units.

4. Cost-Efficient Maintenance

Interchangeable part design and improved thread life reduce long-term service costs for OEM users.

5. Integration-Ready Engineering

Fasteners are modeled to fit directly into CAD and PLM systems, simplifying design and procurement.

Application Scenarios: Where Custom Fasteners Redefine Reliability

-

Heavy Machinery – Bolts and nuts designed for torque stability in engines, compressors, and turbines.

-

Infrastructure Projects – Anchors and expansion bolts engineered for concrete or composite foundations.

-

Automotive & Rail Systems – Anti-vibration fasteners supporting high-speed mechanical joints.

-

Renewable Energy Systems – Corrosion-proof assemblies for wind turbines and solar panel mounts.

-

Aerospace & Defense – Lightweight titanium fasteners achieving high strength-to-weight ratios.

Each sector benefits from material-specific precision that standard parts cannot deliver.

Professional Selection Framework: Matching Fasteners to Application Requirements

Choosing the right fastener begins with understanding performance conditions—load, vibration, temperature, and exposure.

| Application Type | Recommended Material | Coating Type | Key Focus |

|---|---|---|---|

| Outdoor Construction | Hot-dip galvanized steel | Zinc/Nickel | Corrosion protection |

| Automotive Assemblies | Alloy steel / stainless | Phosphate / powder coating | Fatigue resistance |

| Heavy Equipment | High-tensile steel | Ceramic coating | Torque retention |

| Energy & Marine Systems | Duplex stainless / titanium | Anodized / epoxy | Anti-corrosion |

| Precision Instruments | Brass / aluminum | Anodized finish | Electrical insulation |

Expert engineering tips:

-

For assemblies under vibration, use self-locking threads or prevailing torque designs.

-

Specify coefficient of friction (CoF) requirements during design to maintain consistent tightening torque.

-

Always validate salt spray test hours (ASTM B117) for fasteners exposed to moisture or chemicals.

Precision Hardware for Smarter Manufacturing

As automation, energy, and mobility sectors evolve, custom industrial fasteners are redefining reliability standards. The future belongs to hardware designed for specific performance metrics, not generic dimensions.

At Jingle, our OEM customization integrates multi-axis CNC machining, surface coating science, and real-time quality analytics—ensuring each fastener strengthens the systems it connects.

Explore Jingle’s precision-engineered fasteners and discover how we’re securing the future of modern manufacturing. Visit our homepage or reach out via our contact page to discuss tailored production solutions.