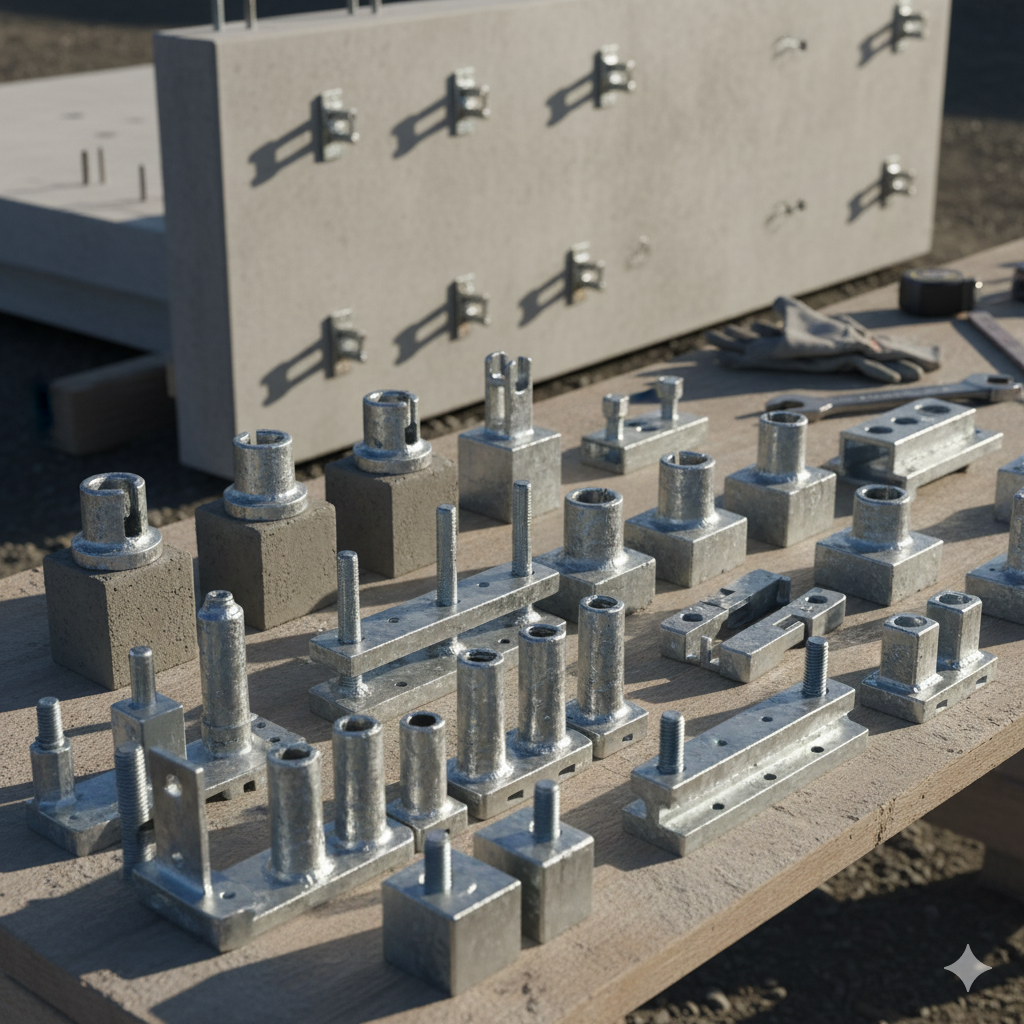

OEM Customization of Galvanized Precast Accessories for Infrastructure Projects

Durability Standards for Infrastructure Lifecycles

Infrastructure works are designed for lifespans measured in decades. The embedded components that secure precast concrete elements must match this expectation. Galvanized finishes extend the service life of steel accessories by resisting corrosion from rain, salt, and industrial environments. According to the American Galvanizers Association (AGA), hot-dip galvanization can provide 50+ years of protection in urban settings and over 100 years in rural environments.

Such long-term performance ensures that anchor plates, lifting systems, and couplers maintain structural stability throughout the entire lifecycle of a project.

OEM Design Flexibility for Structural Integration

Every infrastructure project comes with unique engineering constraints. OEM customization allows accessories to be adapted for load distribution, connection geometry, and installation speed.

| Customized Feature | Engineering Purpose | Performance Benefit |

|---|---|---|

| Load-rated anchors | Bridge decks, viaducts | Distribute force across concrete sections |

| Precision couplers | Metro tunnels, underground systems | Ensure alignment under dynamic loads |

| Threaded inserts | High-rise wall panels | Simplify modular installation |

| Special coatings | Coastal structures | Resist salt spray and humidity |

OEM customization transforms accessories from standard components into project-specific structural enablers.

Managing Quality Across Production Phases

Consistency is crucial when moving from prototypes to high-volume orders. Accessories must retain the same dimensional accuracy and coating integrity across thousands of units. Modern OEM suppliers employ:

-

Automated machining centers to minimize human error.

-

Salt-spray and tensile testing for verifying corrosion resistance and load-bearing capacity.

-

Batch traceability systems that link every shipment to inspection reports.

The European Committee for Standardization (CEN) recommends full documentation for precast components to support compliance and reduce risk in long-term infrastructure audits.

Real-World Applications of Galvanized Precast Accessories

-

Highway Overpasses: hot-dip galvanized anchor plates distribute forces from heavy traffic and extend lifespan under outdoor exposure.

-

Urban Rail Systems: couplers and reinforcement connectors maintain tunnel safety under vibration and groundwater pressure.

-

Residential Towers: lifting systems speed up modular wall placement, reducing construction time without compromising strength.

-

Industrial Facilities: heavy-duty connectors support precast frames that withstand equipment vibration and mechanical loads.

These applications demonstrate how galvanized precast accessories provide both functional reliability and operational efficiency in critical projects.

Q&A: Engineering and Procurement Considerations

Q1: What testing ensures accessories will perform in aggressive environments?

A: Salt-spray tests, load capacity verification, and metallographic inspections confirm that galvanized coatings and steel substrates can withstand decades of exposure.

Q2: How can consistency be guaranteed across mass production?

A: Automated production lines and ISO 9001-certified quality systems maintain dimensional uniformity and coating thickness standards.

Q3: How are international shipments supported?

A: With experience in FOB, CIF, and DDP logistics, Jingle coordinates customs documentation, packaging, and freight solutions tailored to infrastructure projects worldwide.

Why Jingle Leads in OEM Galvanized Precast Accessories

The requirements of infrastructure projects demand suppliers who combine technical expertise, customization capability, and international delivery experience.

At Jingle, we deliver:

-

OEM/ODM customization aligned with project-specific designs.

-

Galvanized accessories with ISO-certified quality and full testing reports.

-

Global export capability, serving Europe, the Middle East, and Asia.

-

Efficient production schedules to support large-scale construction timelines.

Explore our full range of solutions on the homepage or connect with us via our contact page.