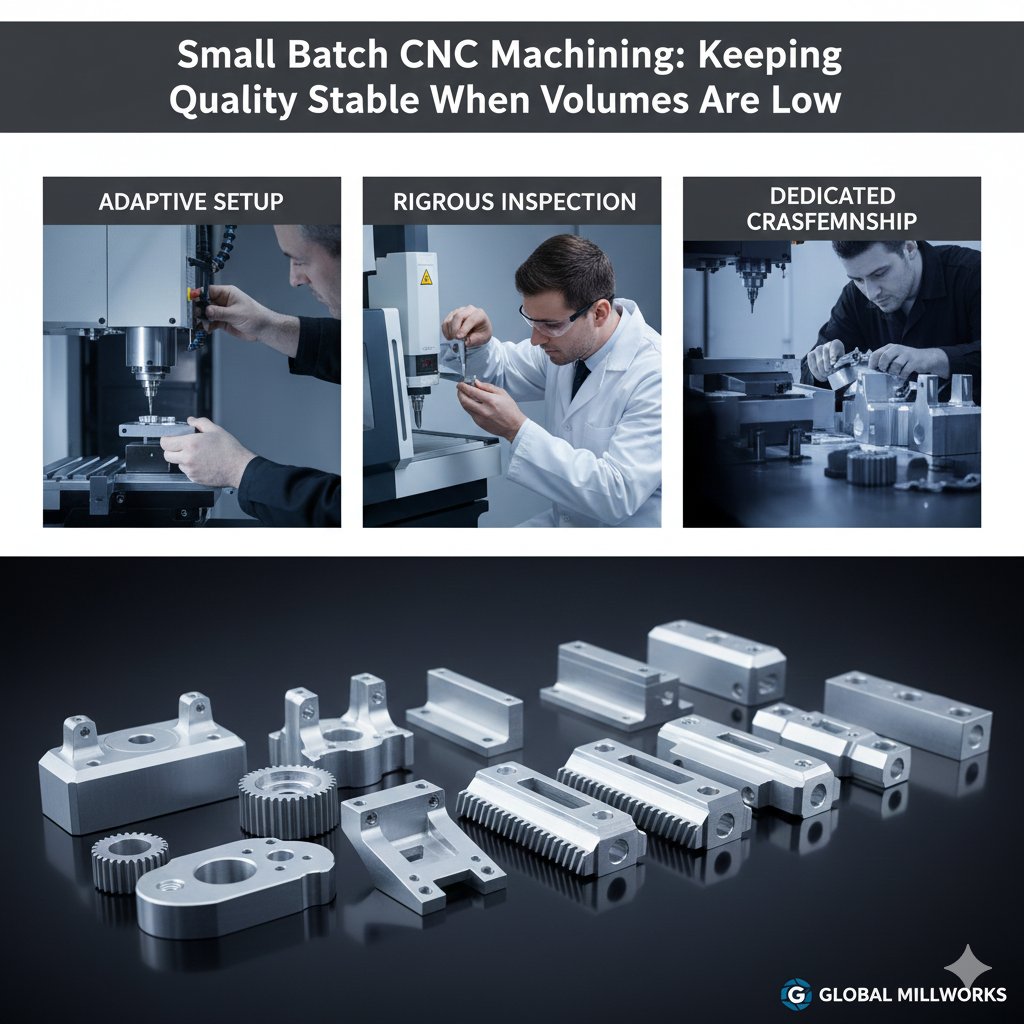

Small Batch CNC Machining: Keeping Quality Stable When Volumes Are Low

Small batch CNC machining is often described as flexible.

In reality, it is less forgiving than high-volume production.

When volumes are low, every setup matters more. Every decision carries a higher cost per part. There is less statistical smoothing, less tolerance for drift, and fewer opportunities to “average out” variation.

This is why small batch CNC machining succeeds only when processes are deliberately controlled—not improvised.

Why Low Volume Increases Risk Instead of Reducing It

At first glance, fewer parts should mean fewer problems.

In practice, the opposite is often true.

Small batch projects face challenges that large runs do not:

-

setup time dominates total cost

-

fixture repeatability is tested less frequently

-

tool wear data is limited

-

inspection feedback loops are shorter

Any inconsistency appears immediately—and directly affects usable output.

Setup Consistency Becomes the Primary Quality Driver

In high-volume production, process drift can be detected gradually.

In small batch CNC machining, there is no buffer.

Each setup must be correct the first time.

| Setup factor | Why it matters more in small batches |

|---|---|

| Datum definition | Prevents rework across setups |

| Fixture repeatability | Maintains feature alignment |

| Program verification | Avoids scrap on first pieces |

| Operator handoff clarity | Reduces interpretation error |

Suppliers who rely on informal setup knowledge struggle as soon as part variation increases.

Fixture Strategy Must Balance Speed and Control

Quick-change fixtures are often favored for small batches.

Speed alone, however, does not guarantee consistency.

Overly flexible fixturing introduces positional variation, especially on complex parts or thin sections. Stable small batch machining requires fixtures that are fast and repeatable.

This balance is one of the clearest indicators of supplier maturity.

Tooling Decisions Carry More Weight at Low Volume

In small batch CNC machining, tool changes are frequent and optimization cycles are short. Poor tooling choices show up immediately as surface inconsistency or dimensional scatter.

Rather than chasing aggressive parameters, experienced suppliers prioritize predictable tool behavior over marginal cycle-time gains.

| Tooling consideration | Impact in small batches |

|---|---|

| Insert geometry | Affects consistency more than speed |

| Tool life tracking | Prevents sudden variation |

| Edge preparation | Improves surface stability |

| Change discipline | Reduces part-to-part drift |

Inspection Strategy Must Be Targeted, Not Broad

Inspecting everything slows small batch projects unnecessarily.

Inspecting the wrong things misses real risk.

Effective small batch CNC machining focuses inspection on functional features—those that determine fit, alignment, or load behavior.

| Inspection focus | Benefit |

|---|---|

| First-off verification | Confirms setup accuracy |

| Critical feature checks | Protects assembly fit |

| Time-delayed inspection | Reveals post-machining movement |

| Dimensional comparison | Detects early drift |

Targeted inspection keeps cost controlled without sacrificing confidence.

Cost Control Is About Avoiding Rework, Not Cutting Time

In low-volume machining, machine time is rarely the main cost driver.

Rework, scrap, and delayed decisions are.

Small batch CNC machining remains economical only when:

-

setups are validated before cutting

-

communication gaps are eliminated early

-

corrections are made once, not repeatedly

This shifts cost control from the shop floor to planning and review.

Scaling Small Batches Without Losing Control

Many projects begin as small batches and grow later.

The transition exposes weaknesses quickly.

Suppliers prepared for this evolution design small batch processes that scale—fixtures that can be reused, programs that tolerate volume increase, and inspection plans that adapt smoothly.

Manufacturers such as Jingle approach small batch CNC machining with scalability in mind, ensuring early-stage work does not become technical debt later.

Where Small Batch CNC Machining Adds the Most Value

Small batch CNC machining is best suited for:

| Application | Typical use case |

|---|---|

| Construction hardware | Trial production and variants |

| Industrial equipment | Replacement and upgrade parts |

| Energy systems | Early-stage assemblies |

| Automation | Custom brackets and mounts |

| Product development | Design validation runs |

In these scenarios, control and clarity matter more than raw speed.

The Real Measure of a Small Batch CNC Supplier

A capable small batch CNC machining partner delivers:

-

predictable results across low volumes

-

clear communication around risk

-

stable setups without trial-and-error

-

parts that assemble correctly the first time

Flexibility without discipline is chaos.

Discipline enables flexibility.

Small Batches Demand Big Control

Small batch CNC machining magnifies every weakness in process control. Suppliers who treat low volume as “simple” often struggle. Those who treat it as high-risk, high-visibility work deliver consistent results even under tight constraints.

That difference determines whether small batches accelerate projects—or delay them.

To explore small batch CNC machining capabilities and related industrial components, visit the Jingle home page or reach out via the contact page for project-specific discussions and documentation support.