In countless industrial, automotive, and domestic applications, the secure transfer of fluids and gases is paramount. The integrity of these systems often relies on a deceptively simple yet critical component: the clamp. This device is fundamental to creating a reliable, leak-proof seal at connection points, particularly where flexible hoses meet rigid fittings. A properly selected and installed clamp ensures system efficiency, prevents loss of valuable materials, and safeguards against potential hazards caused by leaks, making it an unsung hero of mechanical and fluid engineering.

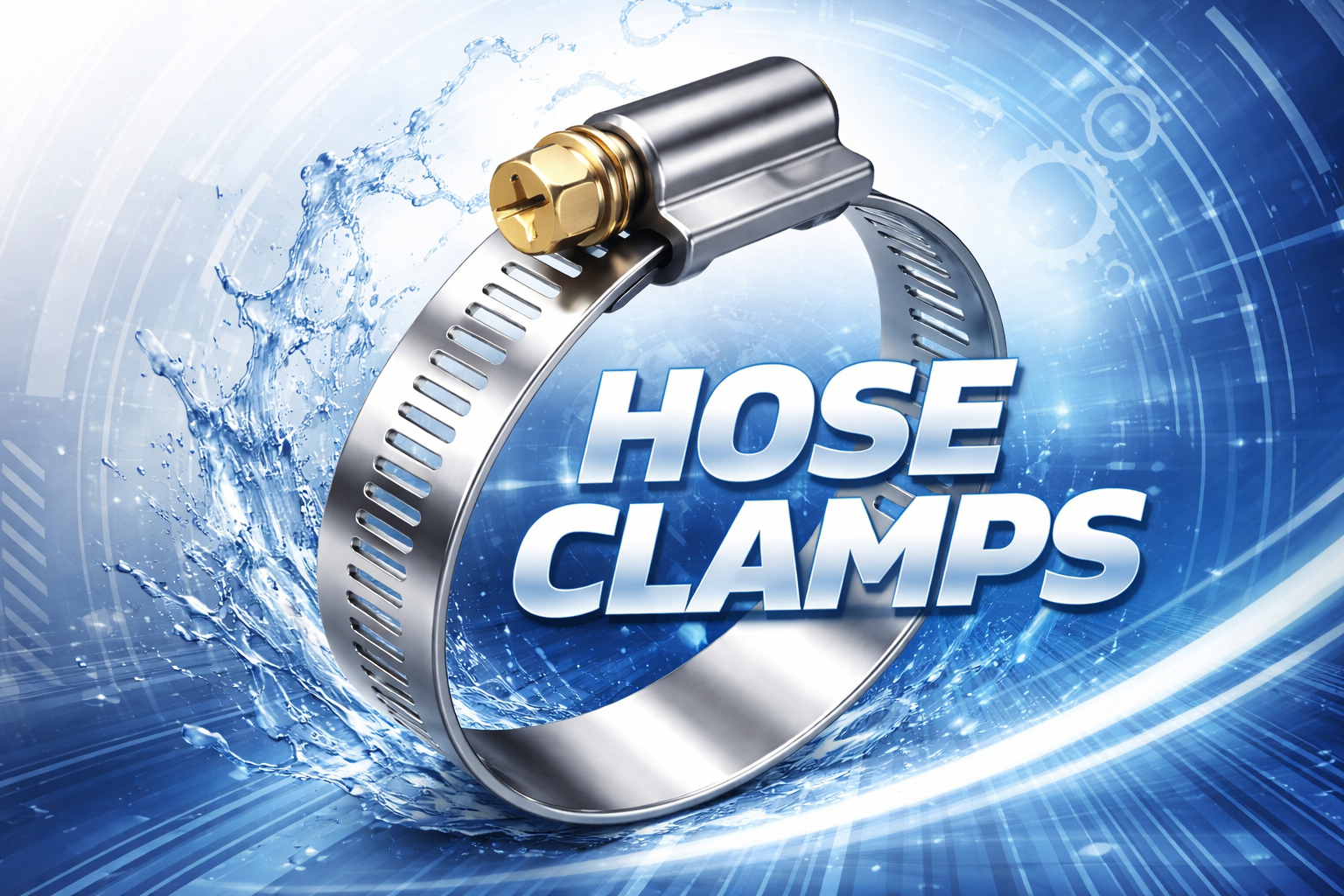

The Technical Anatomy of a Hose Clamp

A standard worm-drive hose clamp, one of the most common types, operates on a straightforward yet effective mechanical principle. It consists of three main parts: the band, the housing, and the screw. The band is typically made from stainless steel and features a series of stamped or cut perforations that act as a screw thread. This band is designed to encircle the hose. The screw, housed within a small casing, engages with these perforations. As the screw is turned clockwise, its threads mesh with the band's perforations, effectively pulling the band through the housing and reducing its diameter. This tightening action applies uniform radial pressure around the circumference of the hose, compressing it against the underlying barb or fitting. Material selection is critical; stainless steel grades like 304 or 316 are chosen for their superior corrosion resistance, while the screw mechanism is engineered to handle specific torque values without stripping, ensuring a durable and secure connection.

Selecting the Right Clamp for the Application

Not all clamping tasks are equal, which has led to the development of various clamp designs tailored for specific conditions. While the worm-drive is a versatile workhorse, high-pressure systems, such as those with turbochargers, often demand a T-bolt clamp. This design utilizes a separate bolt and nut to achieve significantly higher clamping forces and a more uniform pressure distribution, crucial for preventing blow-offs under extreme pressure. For applications involving significant temperature fluctuations, like an engine's cooling system, a spring clamp is often the superior choice. This type of hose clamp is designed to expand and contract with the hose as temperatures change, maintaining constant tension and preventing leaks that might otherwise occur due to thermal cycling. The synergy between hose and clamps is a critical consideration; the clamp must be compatible with the hose material, the transported medium, and the system's operating pressure and temperature to guarantee a lasting seal.

Best Practices for Hose and Clamps Installation

Proper installation technique is just as important as selecting the correct hardware. The process begins with inspecting both the hose and the fitting for any damage, dirt, or oil that could compromise the seal. Once cleared, the hose clamp should be slipped over the hose before the hose is pushed onto the fitting. Correct positioning is vital: the clamp should be placed just behind the last barb of the fitting, not directly on the end of the hose. This ensures the clamping force is applied over the most effective sealing area. When tightening, it is crucial to apply the correct amount of torque. Over-tightening can damage the hose material, leading to splits and premature failure, while under-tightening will result in a weak seal and potential leaks. In mission-critical applications, using a calibrated torque wrench is highly recommended to achieve the manufacturer's specified tightness, ensuring the entire assembly of hose and clamps performs as a reliable and integrated system.

Ensuring System Integrity with Proper Clamping

Ultimately, the performance and safety of any fluid or gas conveyance system are directly tied to the quality of its connections. The humble clamp is the linchpin of this integrity. A deep technical understanding of a clamp's mechanics, the different types available, and the precise installation procedures is not a trivial matter. It is a fundamental aspect of robust engineering design. By carefully considering the application's demands—pressure, temperature, and chemical compatibility—and adhering to installation best practices, one can ensure that these small components provide the reliable, long-term performance required to keep complex systems running smoothly and safely.