Bolt Grades Explained: Which Strength Level Do You Really Need?

Understanding Why a Simple Number Defines Structural Integrity

In engineering and industrial manufacturing, a bolt is far more than a piece of metal—it’s a safety device that holds entire systems together. The “grade” stamped on a bolt head isn’t random. It represents tensile strength, heat treatment, material composition, and—ultimately—the level of responsibility it carries in a design.

At Jingle, we’ve seen too many projects fail not because of poor design, but because the wrong bolt grade was chosen. This guide breaks down what those numbers really mean and how to choose the right strength level for your application.

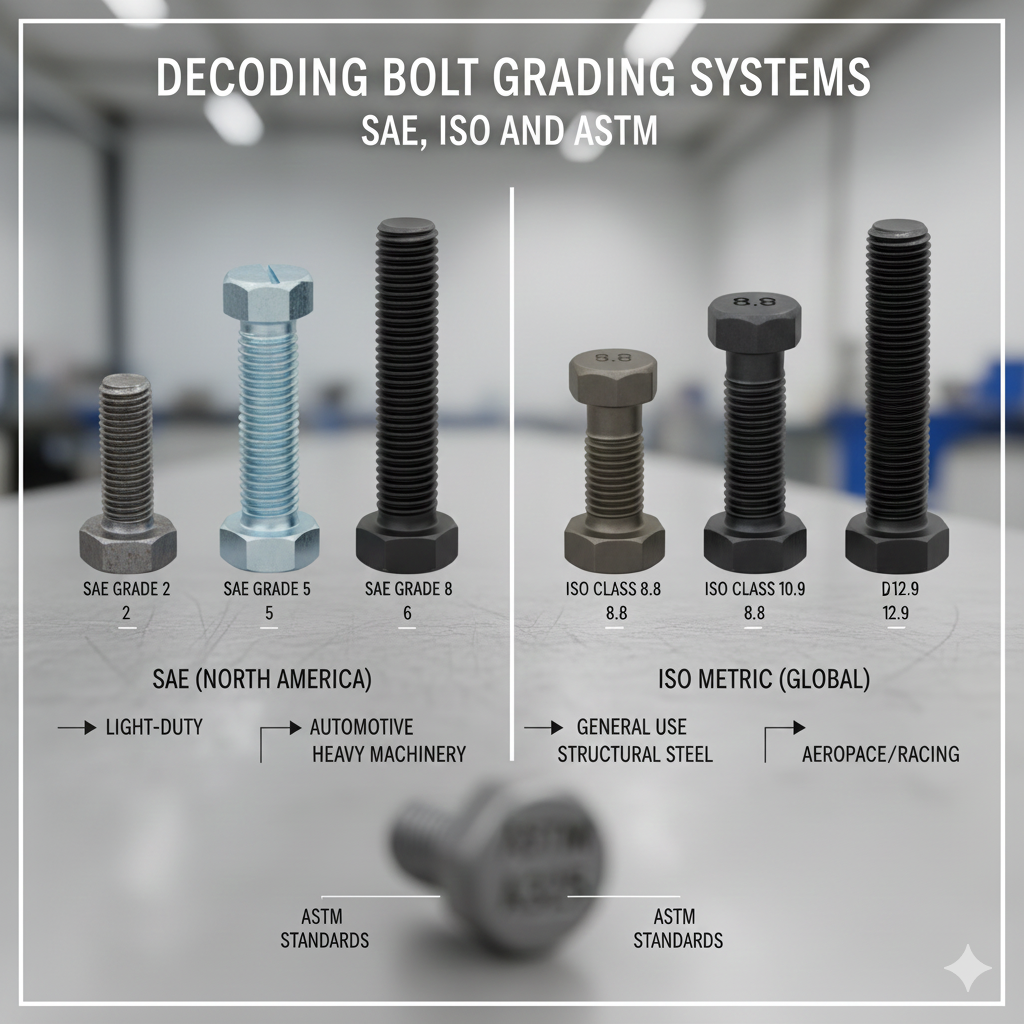

Decoding Bolt Grading Systems: SAE, ISO, and ASTM

Globally, bolts follow several grading systems, each defining different performance levels.

According to the Fasteners Institute, three systems dominate the market:

-

SAE (Society of Automotive Engineers) – Common in North America (e.g., Grade 2, 5, 8)

-

ISO Metric System – Used internationally (e.g., Class 8.8, 10.9, 12.9)

-

ASTM Standards – Structural and high-strength bolts (e.g., ASTM A325, A490)

| System | Grade/Class | Typical Tensile Strength | Common Applications |

|---|---|---|---|

| SAE | Grade 2 | ~60,000 psi (≈414 MPa) | Light-duty or non-critical connections |

| SAE | Grade 5 | ~120,000 psi (≈827 MPa) | General automotive and machinery use |

| SAE | Grade 8 | ~150,000 psi (≈1,034 MPa) | Heavy-duty and structural assemblies |

| ISO | 8.8 | ~800 MPa tensile / 640 MPa yield | Global standard for medium strength |

| ISO | 10.9 | ~1,040 MPa tensile / 940 MPa yield | Structural steel and machinery joints |

| ISO | 12.9 | ~1,220 MPa tensile / 1,100 MPa yield | Aerospace, racing, and extreme loads |

Reference: Bolt Depot & SAE J429 standards

The higher the number, the stronger the bolt—but also the stricter the requirements for material, heat treatment, and testing.

Beyond Strength: When and Why Grade Selection Matters

Choosing the wrong bolt grade is like using household glue on an aircraft panel—it may hold at first, but it won’t last.

1. Light-duty vs heavy-load:

If your assembly supports minimal loads or is easily accessible for maintenance, low grades (Grade 2 or Class 4.6) may suffice.

2. Dynamic vs static loading:

For vibrating or cyclic environments—such as engines, compressors, or rotating assemblies—high-grade bolts (Grade 8 / Class 10.9+) are mandatory to prevent fatigue.

3. Environmental exposure:

Humidity, salt, and temperature extremes accelerate corrosion and fatigue. Consider galvanized or nickel-coated fasteners for coastal and industrial settings.

Common Misconceptions That Cause Failures

-

“Higher grade equals safer.”

Not necessarily. Over-strength bolts can crack if paired with weak materials or insufficient preload. -

“Grade only matters for bolts.”

Wrong. The nut, washer, and torque value must match the same grade class. -

“All bolts marked 10.9 perform the same.”

Only if manufactured and tested to certified standards such as ISO 898-1 or ASTM F3125. -

“Visual inspection is enough.”

Microscopic defects or improper heat treatment often require tensile and hardness testing for validation.

Engineering Considerations Before Choosing a Grade

| Factor | Engineering Insight |

|---|---|

| Load Direction | Determine whether the joint is primarily under shear or tension. |

| Vibration Level | The higher the cyclic load, the greater the risk of fatigue failure. |

| Temperature Range | Extreme heat can weaken even high-grade bolts. |

| Corrosive Environment | Consider stainless or coated options over bare carbon steel. |

| Maintenance Interval | For inaccessible joints, invest in higher grades with longer life cycles. |

Selecting a bolt grade isn’t only about immediate strength—it’s a balance between performance, durability, and economics across the product’s lifespan.

Best Practices After Selecting the Grade

-

Verify head markings – Always confirm the manufacturer’s identification and grade stamp.

-

Ensure proper torque control – Use calibrated torque wrenches or tension measurement methods.

-

Avoid mixed assemblies – Never pair Grade 8 bolts with Grade 5 nuts.

-

Document traceability – Keep mill certificates and batch inspection reports.

-

Schedule re-torquing – Especially for machinery subject to vibration.

At Jingle, our engineers integrate material selection, machining, and coating in one workflow—ensuring your chosen grade performs exactly as intended in real-world conditions.

FAQs

Q1 – Which is better, Grade 5 or Grade 8?

Grade 8 provides higher tensile strength and is ideal for heavy-duty assemblies, but Grade 5 is often sufficient for general machinery.

Q2 – How do ISO and SAE grades compare?

Class 8.8 ≈ Grade 5; Class 10.9 ≈ Grade 8.

Q3 – Can low-grade bolts be used temporarily?

Yes—but only in non-critical structures with controlled load and environment. Always plan for replacement.

Q4 – What standards ensure bolt reliability?

Refer to ISO 898-1, SAE J429, or ASTM A490 for global certification and traceability guidelines.

From Numbers to Reliability: Building Confidence Through Specification

Choosing a bolt grade isn’t a guess—it’s an engineering decision that affects safety, warranty, and long-term cost.

At Jingle, we transform bolt data into dependable solutions—through material expertise, in-house testing, and OEM customization that align with your project’s stress profile and environmental challenges.

Explore our complete range of industrial fasteners at Jingle Homepage or discuss your next project’s specifications with our engineering team via Contact Us.