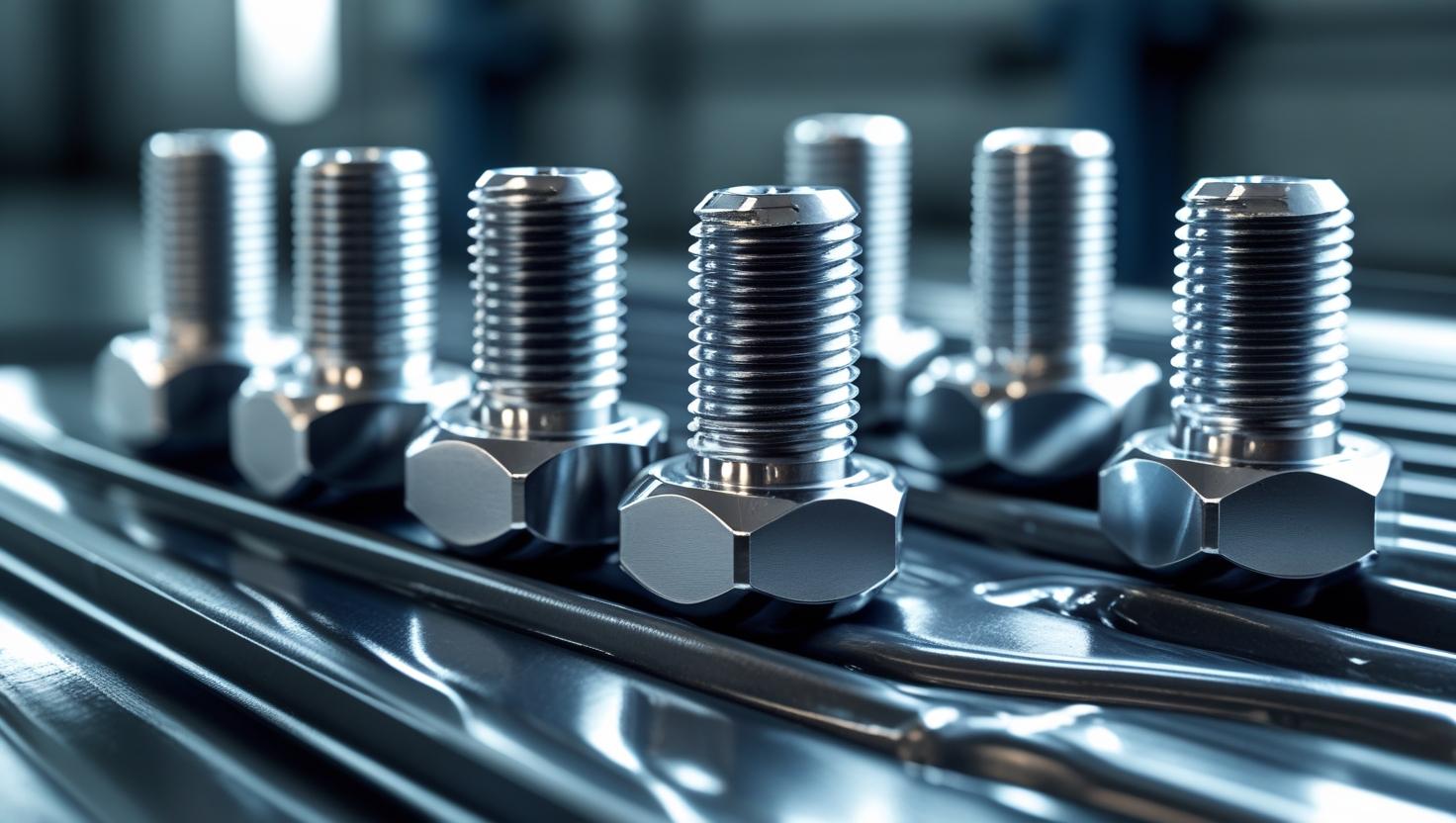

Cap Screws for Industrial Reliability: What Engineers Need to Know

What Are Cap Screws and Why Do They Matter?

Cap screws, often known assocket cap screwsorhex socket bolts, are threaded fasteners designed for high-strength, load-bearing assemblies. Unlike general-purpose bolts, they’re precision-made, typically with tighter tolerances, deeper threads, and high-tensile materials such as alloy steel or stainless steel.

Used extensively in:

-

CNC and machining equipment

-

Automotive assemblies and brake systems

-

Robotics and automation frames

-

Structural steel and aluminum joints

Their strength, reliability, and clean design make them a preferred choice for engineers requiring bothmechanical performanceandassembly efficiency.

Real-World Challenges in Cap Screw Sourcing

If you’ve sourced cap screws before, you may have run into one or more of these issues:

-

Inconsistent thread qualitycausing misfits or stripping

-

Lack of hardness certificationfor high-torque applications

-

Dimensional variancemaking them incompatible with automated feeds

-

Poor corrosion resistance, especially in marine or humid environments

-

Incomplete documentation, affecting customs clearance and compliance

Whether you’re an OEM buyer or a maintenance lead, these problems cost time, increase warranty claims, and risk project integrity.

Choosing the Right Cap Screw for Your Application

Not all cap screws are created equal. You should match based on:

| Application | Best Cap Screw Type | Material |

|---|---|---|

| High-load mechanical parts | Socket head cap screw | Alloy Steel (Grade 12.9) |

| Corrosive outdoor settings | Button head cap screw | SS304 / SS316 |

| Space-constrained assemblies | Low-profile cap screw | Zinc-plated Steel |

| Aesthetic finish | Black oxide cap screw | Stainless or carbon steel |

Jingleoffers a wide variety of cap screws in both metric and inch sizes, customizable to client drawings or kits.

From Bulk Supply to Custom Kits: What Makes a Great Supplier

Bulk buyers and OEMs often face gaps in logistics or communication. A capable cap screw supplier must offer more than just SKUs:

-

Custom packagingper application scenario

-

Batch traceability and inspection reports(ISO, RoHS, etc.)

-

CAD drawing support and technical consulting

-

Flexible MOQfor pilot and mass production

-

Fast response and documentation readiness: CO, CI, PL, MSDS, etc.

AtJingle, we provide OEM services, component bundling, and cap screw kits tailored for automated production lines or maintenance workflows—helping clients avoid rework and downtime.

Secure and Streamline Your Assembly with the Right Cap Screws

When mechanical reliability matters, cap screws are not the place to compromise. Choosing the right grade, finish, and supplier ensures both performance and efficiency across every application.

Need socket cap screws for high-torque assemblies? Or corrosion-resistant fasteners for marine use?Jingleis ready to support your next build.

🔗Explore our products

📩Talk to our teamfor technical advice or custom quotations.