Why 5G Modules Demand Advanced Enclosures

The leap from 4G to 5G dramatically increases signal frequency, data throughput, and system complexity. These improvements also bring vulnerabilities:

-

Heat accumulation from high data transfer rates.

-

Electromagnetic interference (EMI) disrupting stable connections.

-

Compact integration challenges as devices become smaller but more powerful.

-

Outdoor exposure in base stations and smart city infrastructure.

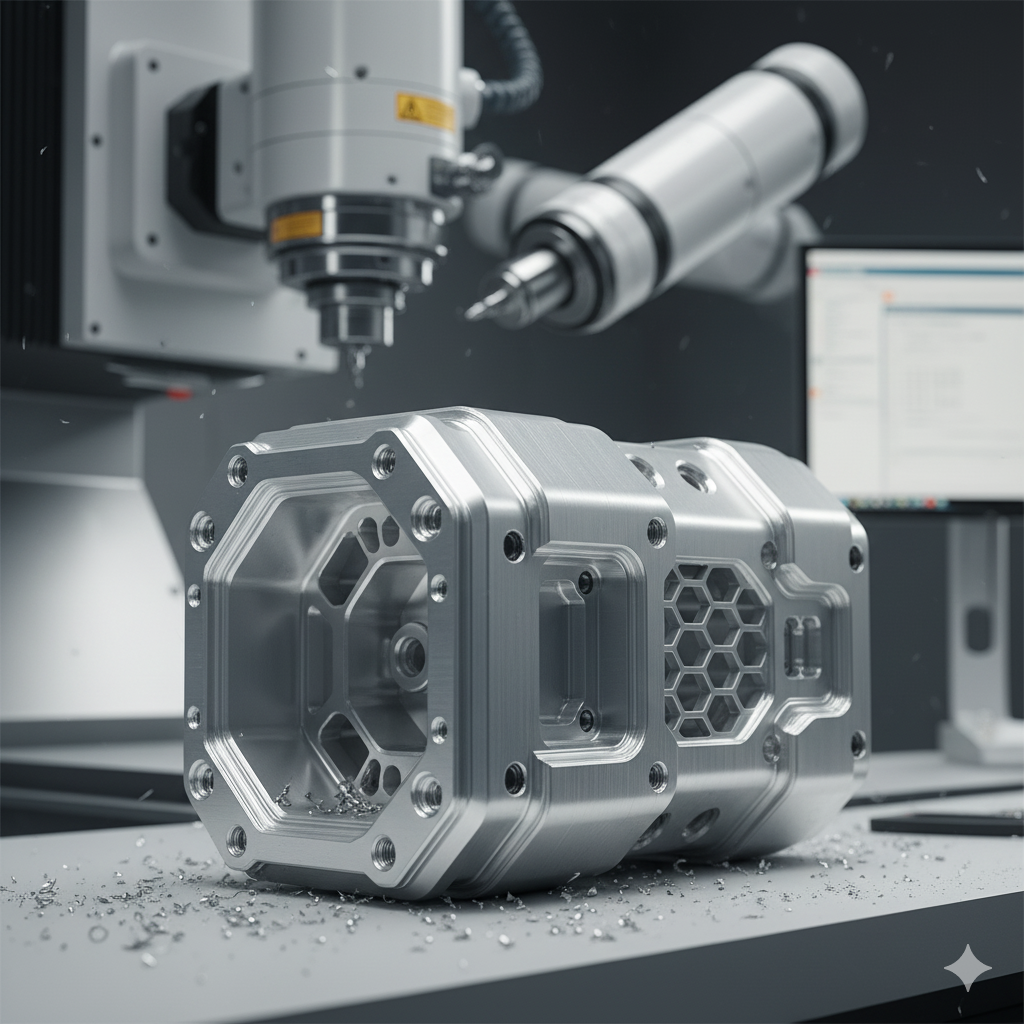

Generic housings often fail in these conditions. CNC machined enclosures address these challenges by combining mechanical strength with precision tailoring, ensuring 5G modules perform reliably.

Engineering Details That Make the Difference

CNC machining delivers enclosures designed with engineering precision, critical for 5G hardware performance:

-

Ultra-tight tolerances (±0.01 mm) ensure modules fit without stress or misalignment.

-

Heat-dissipation pathways reduce overheating in compact designs.

-

EMI shielding channels prevent frequency interference between modules.

-

Surface finishes improve corrosion resistance for outdoor telecom environments.

-

Lightweight alloys balance durability with portability.

Comparative Overview of Enclosure Options

| Feature | Cast/Stamped Housings | CNC Machined Enclosures (JINGLE OEM) |

|---|---|---|

| Dimensional Tolerance | ±0.2 mm | ±0.01 mm precision |

| Thermal Management | Passive, limited | Integrated cooling pathways |

| EMI Protection | Coatings only | Shielding geometry + coatings |

| Durability in Harsh Use | Moderate | High vibration, heat & weather proof |

| OEM Adaptability | Standardized only | Fully customizable |

Real-World Applications Across the 5G Ecosystem

CNC machined enclosures are not just protective shells—they are enablers of industry-specific performance:

-

Telecom Base Stations – Ruggedized housings withstand rain, dust, and temperature swings.

-

IoT Devices – Compact enclosures secure miniaturized 5G modules in smart city sensors.

-

Medical Equipment – Sterile, corrosion-resistant housings protect wireless surgical devices.

-

Industrial Robotics – Enclosures shield communication modules from vibration and chemicals.

-

5G Gateways – Custom geometries fit constrained designs while maintaining cooling efficiency.

This versatility shows how CNC enclosures serve as cross-industry solutions, not one-size-fits-all parts.

How OEM Manufacturing Adds Strategic Value

From a buyer’s perspective, the challenge is not just sourcing enclosures but ensuring they align with specific design and compliance requirements. JINGLE, as an OEM factory, bridges this gap by offering:

-

Custom Prototyping – small-batch samples tailored for R&D labs.

-

Scalable Mass Production – CNC-controlled processes ensure uniformity across thousands of units.

-

Material Expertise – from lightweight magnesium for handhelds to stainless steel for outdoor stations.

-

Certifications & Compliance – ISO9001, CE, and telecom-grade EMI standards.

This combination reduces risk, shortens product cycles, and ensures enclosures evolve with 5G innovation.

Common Questions Answered

Q1: How do CNC machined enclosures manage the heat of compact 5G modules?

By integrating heat sinks and ventilation paths directly into the housing design, avoiding the need for bulky external cooling.

Q2: Are these enclosures adaptable to IoT or robotic applications?

Yes. OEM customization ensures compatibility with modular systems across industries, from industrial robots to medical devices.

Q3: Will CNC enclosures add significant weight to devices?

No. Alloys such as aluminum and magnesium provide a balance of strength and lightweight efficiency.

Q4: How do these housings improve EMI performance?

Machining allows precise placement of shielding barriers, combined with conductive coatings, ensuring signal stability even in dense networks.

CNC Enclosures as Strategic Infrastructure

As industries adopt 5G, enclosures must evolve from being passive shells into active enablers of performance. CNC machining delivers housings that:

-

Safeguard modules in extreme environments.

-

Enhance thermal and EMI management.

-

Enable OEM flexibility for different industries.

-

Scale seamlessly from prototype to global rollout.

With CNC precision, 5G modules are not only protected but also optimized for longevity and efficiency.

Learn more about JINGLE’s CNC machining enclosure solutions on the homepage or connect directly via the contact page.