Essential Fastener Solutions for Construction Projects

The Real Risk of Fastener Failure in Construction

Fasteners are often overlooked—but on construction sites, they bear immense responsibility.A single failed bolt in a foundation, curtain wall, or prefab module can lead to severe structural risk, costly delays, or even legal liabilities. Construction professionals face three major pain点:

-

Corrosion in exposed environmentsleads to bolt weakening and safety hazards

-

Mismatch in embedded partscauses panel misalignment and on-site rework

-

Unreliable supply or poor-quality batchesdelay timelines and harm client trust

According to a 2023 study by the European Structural Steel Association,over 18% of on-site delays in prefab projects are due to anchoring or embedded part issues.

Corrosion Resistance Isn’t Optional—It’s Safety-Critical

Real Use Case

An EU infrastructure firm reported that bolts used on a bridge parapet began corroding within 14 months, requiring early replacement.

Our Response

-

Hot-dip galvanized, Dacromet-coated, and stainless-steelISO-certified construction bolts

-

Salt spray testing (up to 500+ hours) in our internal lab

-

Material traceability and test reports included in every shipment

Scene-Based Tip

Outdoor steel structures (e.g., railings, shade canopies)must use bolts with long-term anti-rust protection, especially in coastal or high-humidity zones.

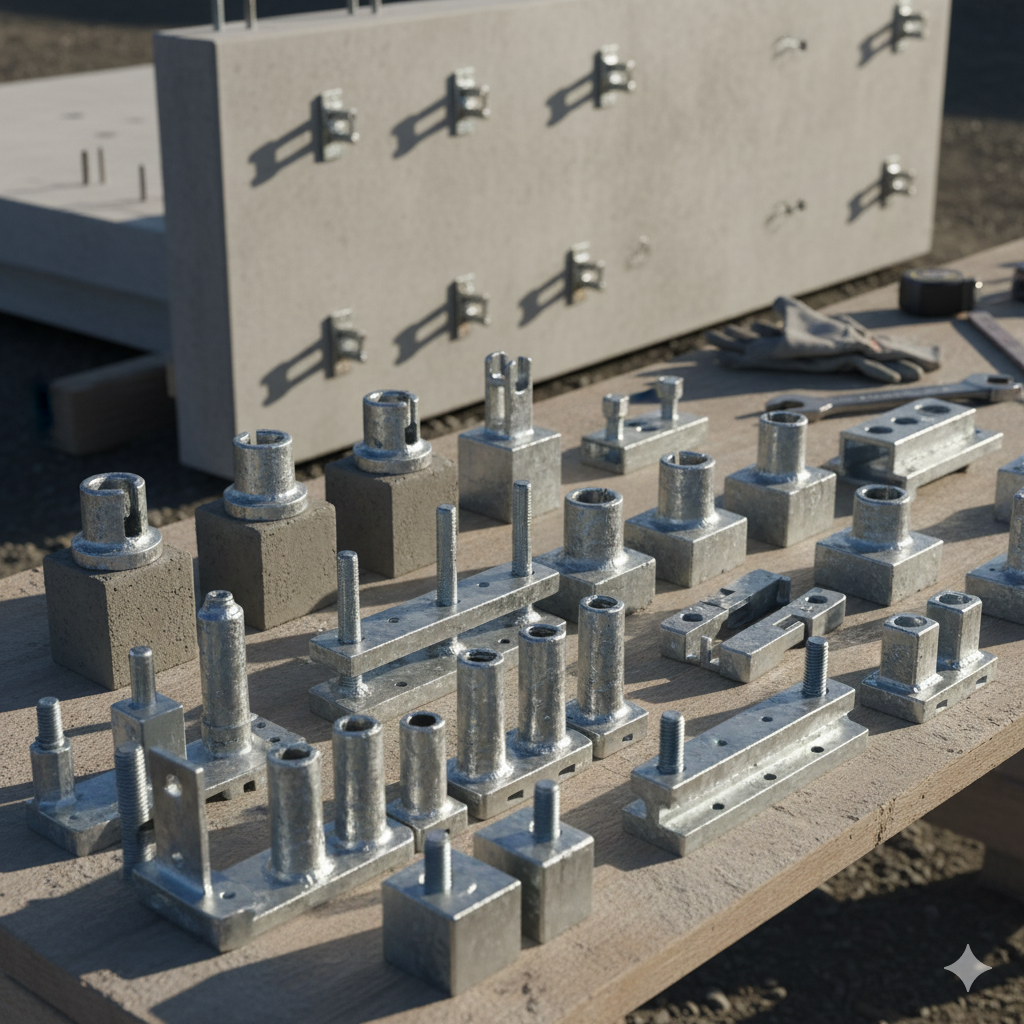

Precision Matters in Prefab Embedded Parts

Real Use Case

A German prefab builder reported a 3-day delay on-site due to embedded rebar cages that were 3 mm off from the panel design.

Our Solution

-

Custom embedded parts for prefabproduced to ±0.02 mm tolerances

-

2D/3D drawing support for project-specific requirements

-

Batch inspections before shipment to verify fit

Scene-Based Tip

Modular housing or façade unitsrequire tight tolerance fasteners and inserts to ensure flush installation—reducing crane hours and labor costs.

Don’t Let Last-Minute Custom Requests Derail Timelines

Real Use Case

A Southeast Asian contractor needed 500 sets of oversized anchor bolts in 10 days for an emergency foundation retrofit.

Our Response

-

In-house CNC and forging lines with flexible setup

-

Rapid prototyping for non-standard bolts or embedded sockets

-

Full compliance with ISO9001 and third-party inspection on urgent orders

Result:Products delivered on time and passed SGS third-party testing.

Why Construction Teams Choose JINGLE

| Feature | What It Solves |

|---|---|

| ISO/CE-certified products | Meet legal and safety requirements |

| Salt spray & tensile testing | Withstand weather and stress |

| Full-process traceability | Meet documentation & inspection demands |

| Design-to-delivery support | Handle urgent or project-specific changes |

Choosing the Right Fasteners for Construction Projects

To avoid costly rework or failures, construction engineers should:

-

Match material to environment

-

Use stainless steel or coated bolts for exterior or marine structures

-

-

Validate load-bearing requirements

-

Request proof load and tensile reports

-

-

Align with prefab tolerances

-

Ensure embedded parts match the mold design precisely

-

-

Confirm documentation readiness

-

CE, ISO, and lab certificates speed up site approval

-

-

Plan for emergency sourcing

-

Partner with suppliers like JINGLE with fast turnaround capacity

-

Build Safer and Smarter with Proven Fastener Solutions

Construction doesn’t wait—and neither should your components. With access toconstruction fasteners for concrete,corrosion-resistant fasteners for building, andcustom embedded parts for prefab, you can ensure:

-

Compliance with global standards

-

Efficient job-site assembly

-

Lasting strength and reliability backed by testing and certification

Contact us todayto get a tailored quote, request samples, or submit your drawings for expert support.