Fastening Challenges in Electric Vehicle Systems—and How to Solve Them

EV Power Systems: A New Set of Stress Factors for Fasteners

Electric vehicles (EVs) introduce unique engineering challenges. Unlike ICE vehicles, they involvehigh voltages,tighter compartments, andmore complex thermal & vibration environments.

According to a 2024 IEA study,EVs will represent 45% of global passenger car sales by 2030, and 63% of Tier 1 suppliers surveyed reportedincreased fastener failure ratesduring EV test cycles compared to ICE systems.

Common Failure Risks in EV Fastener Use

| Risk Factor | Root Cause | Consequences |

|---|---|---|

| Galvanic corrosion | Aluminum/copper contacts + moisture | Electrical failure or loosening |

| Dielectric breakdown | Conductive fasteners near busbars | Short-circuits, fire hazard |

| Vibration fatigue | High acceleration + compact packaging | Loosening bolts, broken brackets |

| Thermal mismatch | Expansion between steel and polymer parts | Casing cracks, misalignment |

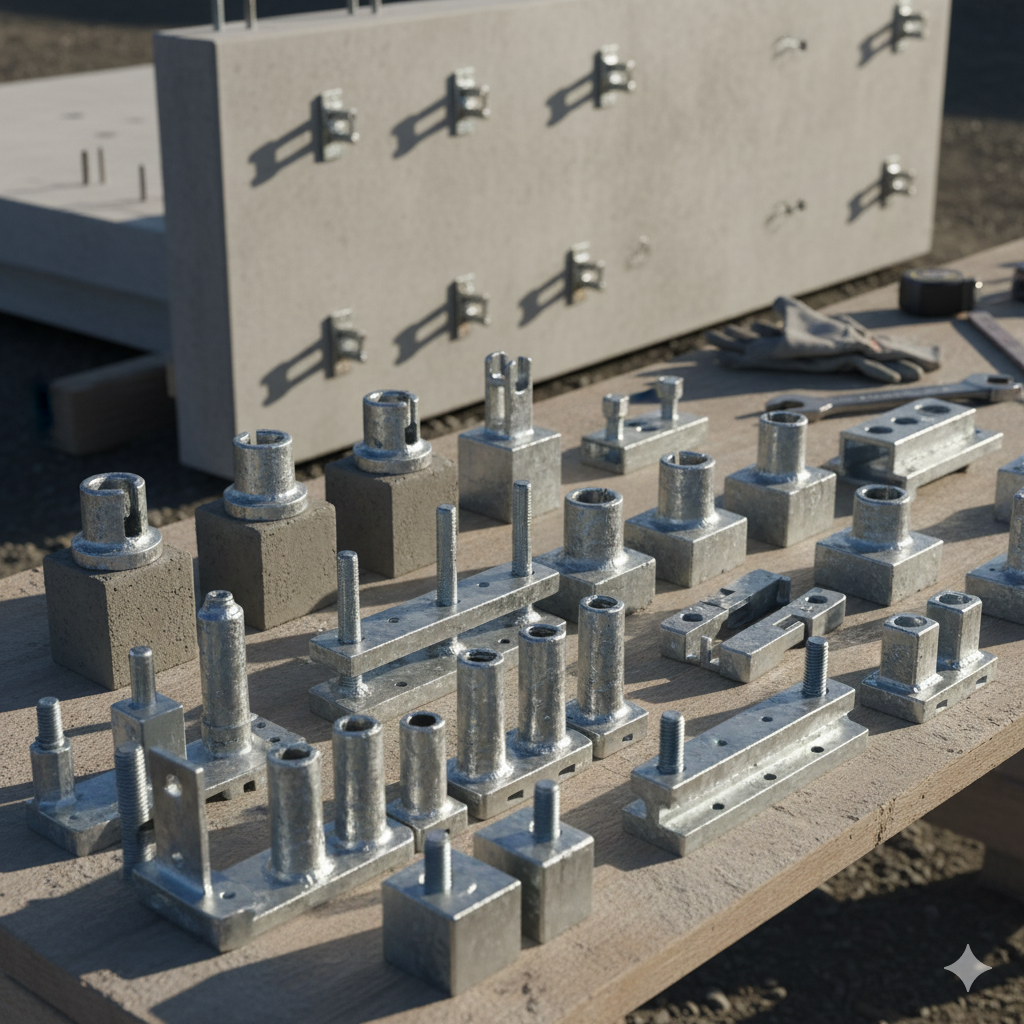

Use Case: Battery Pack Assembly – Material Meets Design

A North American EV startup experiencedinconsistent torque behaviorwhen using standard coated steel bolts on aluminum battery trays. Over-torquing caused micro-cracks; under-torquing led to busbar instability.

JINGLE’s Solution

-

Battery pack boltsusing A2 stainless with nylon insulating washer sets

-

Controlled thread finish for precise torque coefficient

-

Heat-treated and passivated to prevent micro-corrosion

Result: Assembly variation dropped by 84%; bolts passed 96-hour salt spray and electrical leakage tests.

Use Case: Motor Mounting & Insulated Brackets

In compact e-axle motor housings, a client requiredbrackets with both mechanical strength and partial insulation, to separate high-voltage elements from chassis contact points.

JINGLE’s Response

-

CNC-machinedinsulated CNC bracketsfrom hybrid composite-aluminum stock

-

PTFE-treated bolt kits for secured assembly with electrical barrier

-

Delivered with laser markings and matched pairs for mirrored parts

Result: Passed CE and UL insulation clearance protocols; enabled the client’s regulatory clearance for EU and US export.

Design Principles for EV-Focused Fasteners & CNC Parts

-

Use stainless or coated aluminum to avoid galvanic mismatch

-

Incorporate dielectric barriers or washerswhere current proximity exists

-

Design for tight torque control and preload consistency

-

Validate thermal cycling effectson mixed-material contact points

-

Trace batch performance across vehicle lifespanwith stamped IDs and test logs

JINGLE Capabilities Supporting EV Suppliers

| Capability | EV Value |

|---|---|

| ISO 9001, TS16949, CE certified | Global compliance across markets |

| CNC precision to ±0.01 mm | Perfect fit for modules, trays, and mounts |

| Nylon/PVC insulating options | Ensures safety in high-voltage zones |

| Salt spray testing (96h+) | Prevents battery-side corrosion |

| Custom kits per BOM | Speeds up module-level pre-assembly |

Secure Your EV Component Supply with Confidence

If you're scaling EV platforms, upgrading hybrid drive systems, or preparing for regulatory audits in Europe or North America, your fasteners can’t just “fit”—they mustperform, insulate, and comply.

With JINGLE’s support, you get:

-

EV-specific CNC brackets & battery pack fasteners

-

Certified torque, corrosion, and insulation performance

-

Design validation and fast prototyping

-

Batch traceability and pre-assembled packaging

EV engineering is complex—but sourcing the right fasteners doesn’t have to be.Partner with JINGLE to build better, safer electric vehicles.