How Heavy-Duty Fasteners Support Structural Integrity in Construction

1. The Backbone of Every Structure

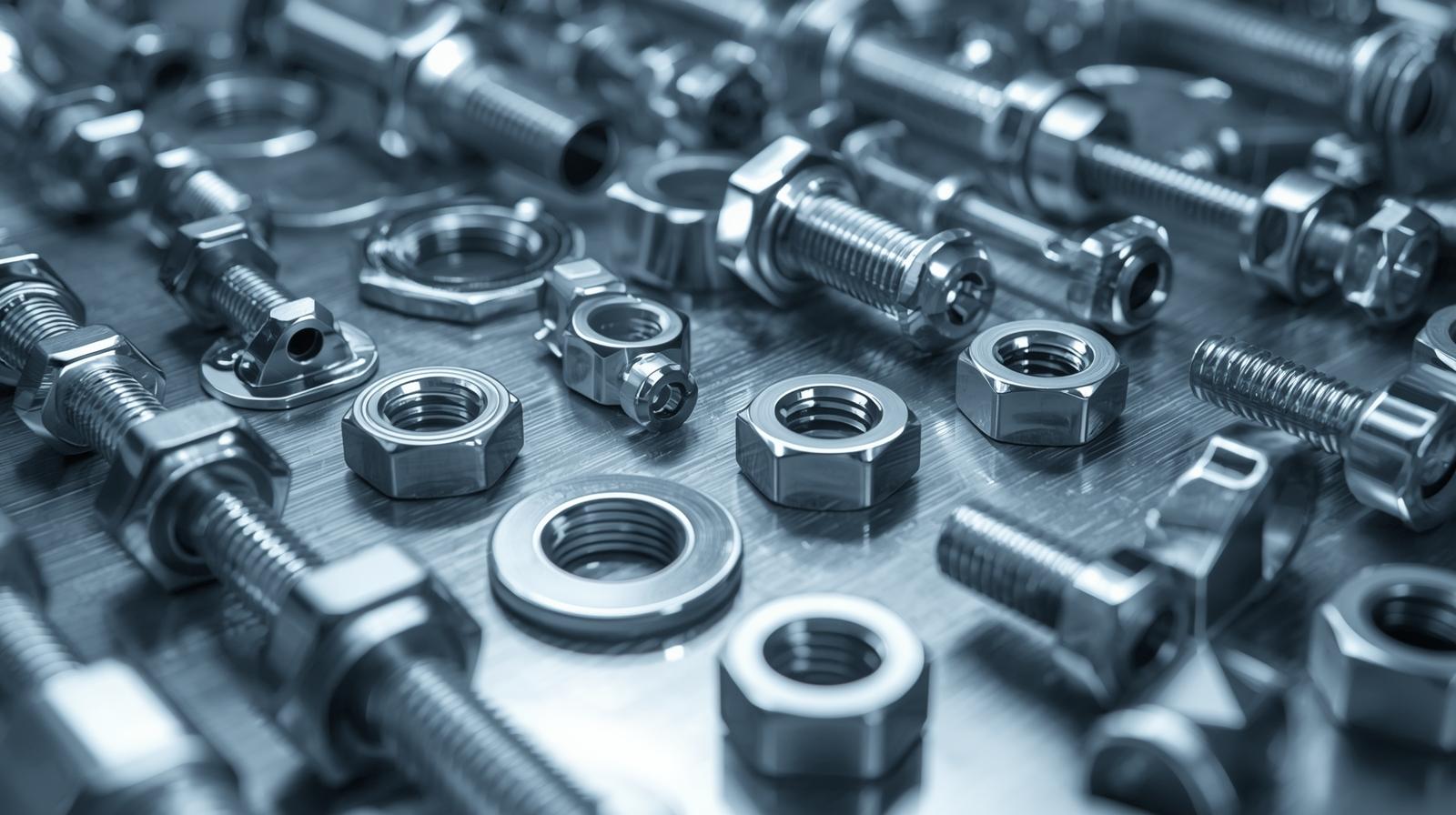

Behind every skyscraper, bridge, or steel frame lies an array of fasteners that silently carry immense loads. Heavy-duty fasteners—including high-tensile bolts, structural nuts, washers, and anchor systems—are engineered to maintain alignment, absorb vibration, and resist environmental stress.

They are the mechanical “joints” of the built world, converting torque into holding force that ensures stability for decades. Choosing the right grade and coating of fasteners determines whether a structure endures time, load, and weather.

2. What Defines a Heavy-Duty Fastener

Heavy-duty fasteners are specifically designed for high-stress applications where strength, ductility, and fatigue resistance are critical.

They differ from standard bolts through their:

-

Material composition (alloy or heat-treated steel)

-

Tensile grade (8.8, 10.9, or 12.9)

-

Thread accuracy and torque tolerance

-

Surface treatment for corrosion control

A typical structural fastener set includes:

-

Bolt: provides clamping force.

-

Nut: maintains joint tension.

-

Washer: distributes load and prevents surface damage.

Each element must meet precise mechanical properties and dimensional standards such as ISO 898-1, ASTM A325, and DIN EN 14399 to ensure predictable performance in dynamic or static loads.

3. Material and Coating: The Dual Shield of Strength

Material selection is the foundation of load capacity, while coating protects against the environment.

| Material | Tensile Strength | Coating Type | Application |

|---|---|---|---|

| Alloy Steel 8.8 / 10.9 | 800–1000 MPa | Hot-dip galvanizing | Structural steel frames |

| Carbon Steel | 400–600 MPa | Electro-zinc plating | Indoor or mild climates |

| Stainless Steel 304 / 316 | 700–850 MPa | Passivated finish | Coastal or chemical sites |

Surface coatings such as Dacromet, HDG, or mechanical plating extend fastener life by preventing rust and maintaining friction consistency.

Jingle applies automated galvanizing and torque verification to ensure consistent preload during assembly and long-term joint stability.

4. Mechanical Design for Structural Safety

The performance of a heavy-duty fastener is not determined by strength alone—it’s about how forces are distributed.

Designers focus on:

-

Thread engagement length to balance clamping and shear resistance.

-

Head geometry to avoid localized stress concentrations.

-

Preload control to minimize fatigue from repeated load cycles.

-

Shear and slip factors critical for steel-to-steel joints.

Advanced production uses cold-forging and CNC rolling to achieve exact thread profiles, ensuring uniform torque transfer and fatigue endurance over millions of cycles.

5. Applications Across Modern Construction

| Construction Type | Fastener Use | Core Requirement |

|---|---|---|

| Steel Structures | Frame joints, girders, beams | High tensile strength |

| Bridges | Expansion joints, rail fixings | Anti-vibration capacity |

| High-Rise Buildings | Column-beam connections | Load uniformity |

| Precast Concrete | Embedded anchors | Pull-out resistance |

| Industrial Plants | Equipment mounting | Long-term torque stability |

Each application requires specific fastener grades and coatings depending on exposure level, expected load, and maintenance accessibility.

6. Testing Standards That Guarantee Performance

Heavy-duty fasteners must pass stringent testing before being approved for structural use. Common quality control procedures include:

-

Tensile test (ASTM E8): verifies mechanical strength.

-

Torque and tension test (ISO 16047): ensures proper preload range.

-

Salt-spray test (ASTM B117): measures corrosion endurance.

-

Fatigue testing: simulates long-term cyclic loads.

-

Dimensional inspection: checks thread pitch, concentricity, and tolerance.

Jingle integrates these tests in both in-house and third-party audits (SGS, TÜV) to ensure global compliance and traceability for every lot.

7. Advantages That Matter to Engineers and Builders

| Advantage | Description | Impact |

|---|---|---|

| High load capacity | Handles extreme stress | Reduces joint failure risk |

| Anti-corrosion finish | Withstands harsh climates | Lowers maintenance cost |

| Dimensional precision | Ensures smooth installation | Improves project efficiency |

| Custom specification | Available in varied grades | Fits diverse project needs |

Well-manufactured fasteners are not only components but also safety assurances embedded in every structure.

8. Selecting the Right Fastener Supplier

When choosing a supplier for large-scale construction projects, reliability comes first. Key factors include:

-

Certifications: ISO 9001, CE, and EN 15048.

-

Material traceability: heat numbers and testing documentation.

-

Customization: tailored diameters, coatings, and packaging.

-

Lead time consistency: critical for infrastructure projects.

Partnering with a professional manufacturer ensures stable supply chains and reduced risk across project timelines.

9. Strength That Shapes the Skyline

Every bolt and nut in a construction project carries more than just metal—it carries the trust of engineers and the safety of people.

Heavy-duty fasteners form the invisible framework of progress, providing strength that allows concrete, steel, and design to coexist seamlessly.

To learn more about high-performance structural fasteners, visit the Jingle Home Page

or contact our specialists through the Contact Page for detailed product consultation and specification support.