What Makes a Great Nut Head for Export and Wholesale: Insights from the Field

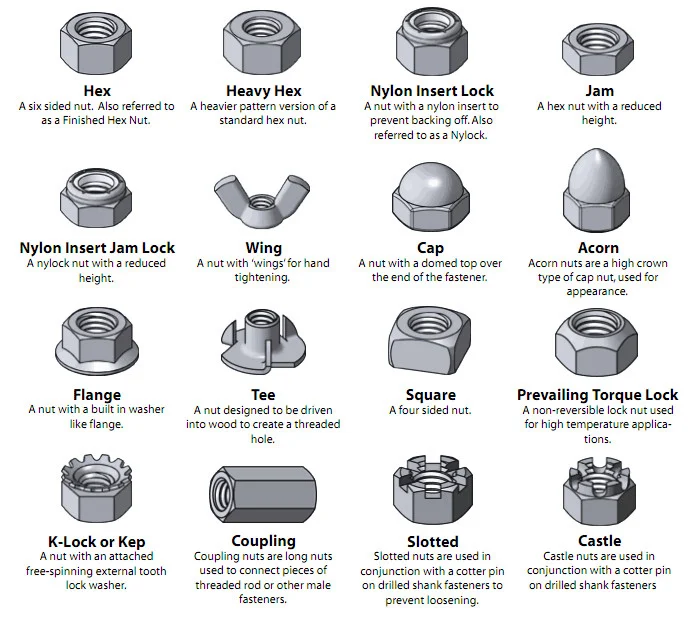

In global industrial supply chains,nut headsare more than just shapes—they define the interface between torque, fit, and field reliability. Whether you’re managing wholesale distribution or sourcing for international projects, choosing the rightnut export headorwholesale configurationcan significantly reduce mechanical failures and shipping risks.

Why the Nut Head Matters More Than You Think

The “head” of a nut refers to its gripping or locking surface—the part that interfaces with tools or mechanical loads. In real-world applications, these often dictate:

-

Ease of assembly/disassembly

-

Resistance to slippage and stripping

-

Torque tolerance and mechanical stress

-

Compatibility with automation or field tools

A buyer sourcinghex nuts for solar installationsorwing nuts for tool-free repair kitswill require different tolerances, plating, and thread pitches. At Jingle, we supply bothstandardized and custom nut headsfor wholesale and export—each tested under industry-grade standards.

Export Expectations: It’s Not Just About the Hardware

Global buyers often face delays not from bad products—but from incomplete packaging, improper labeling, or missing documentation. That’s why ournut export headsolutions come with:

-

Neutral packaging with English labels

-

Export documentation: Commercial invoice, packing list, Certificate of Origin (CO), and customs HS codes

-

Batch-level traceability: Lot codes tied to QC records

-

Kit assemblyoptions for grouped components (with bolts/washers)

This attention toexport readinesssaves time at customs and ensures compliance for EPCs, OEMs, and regional distributors.

Automotive Components Distributor

A German automotive parts distributor requiredlocking nut headsin various thread sizes, packed inretail-friendly setsfor their B2B customers. Key requirements included:

-

DIN-compliant head shapes

-

Laser-etched part numbers

-

Recyclable plastic packaging with barcode

-

Full RoHS and REACH documentation

Jingle delivered a full run within 15 business days, reducing their regional warehouse delays by 22%.

What Wholesale Buyers Really Need

When purchasing in bulk, especially for resale or reassembly,wholesale nut headsmust:

| Criteria | Why It Matters |

|---|---|

| Head Type Consistency | Avoids mismatches during high-volume production |

| Material Grading | Impacts mechanical strength and lifespan |

| Finish Quality | Prevents corrosion and aesthetic defects |

| Cost Efficiency | Influences margin, especially in competitive markets |

That’s why Jingle supports:

-

Carbon steel, stainless steel, brass nut head options

-

Custom head designs for automation or branding

-

Bulk packaging with MOQ flexibility

-

Dedicated support for wholesale reorders and private labeling

From Workshop Design to Global Shipment: Jingle’s Full-Cycle Support

At Jingle, we don’t just sell parts—we help industrial buyers build reliable systems. Our nut head products are manufactured under a full ISO-compliant process, covering:

-

Precision machiningwith strict tolerance control

-

Material verificationthrough third-party testing

-

Salt spray & torque resistance testsbefore shipment

-

Custom documentationsupport for bulk/export clients

-

OEM logo etching or packagingon request

Whether you’re preparing a government tender, B2B resale line, or long-term procurement contract, ournut factory kitsare engineered to support your real business needs.

Secure the Right Nut Head, the First Time

Don’t let mismatched heads or incomplete export paperwork delay your project. Jingle’snut export headandnut wholesale headsolutions are designed for global buyers who need speed, reliability, and long-term support.

View our full catalog atjinglefix.com, orcontact us hereto request samples, compliance files, or a tailored quote.