Precision-Ready: How Nut Custom Parts Improve Assembly Efficiency

The Real Challenge Behind Sourcing Nuts

For procurement managers in machinery, automotive, or electrical industries, sourcing nuts sounds simple—until it’s not. You face questions like:

-

Are these nuts 100% compatible with our bolts or fittings?

-

Can the supplier meet our thread pitch, coating, or torque specs?

-

How are the parts packed—can they go directly into our lines?

-

Who handles the export documentation and labeling?

That’s where nut custom parts and ready-to-use nut OEM kits become essential to streamline the process from design to delivery.

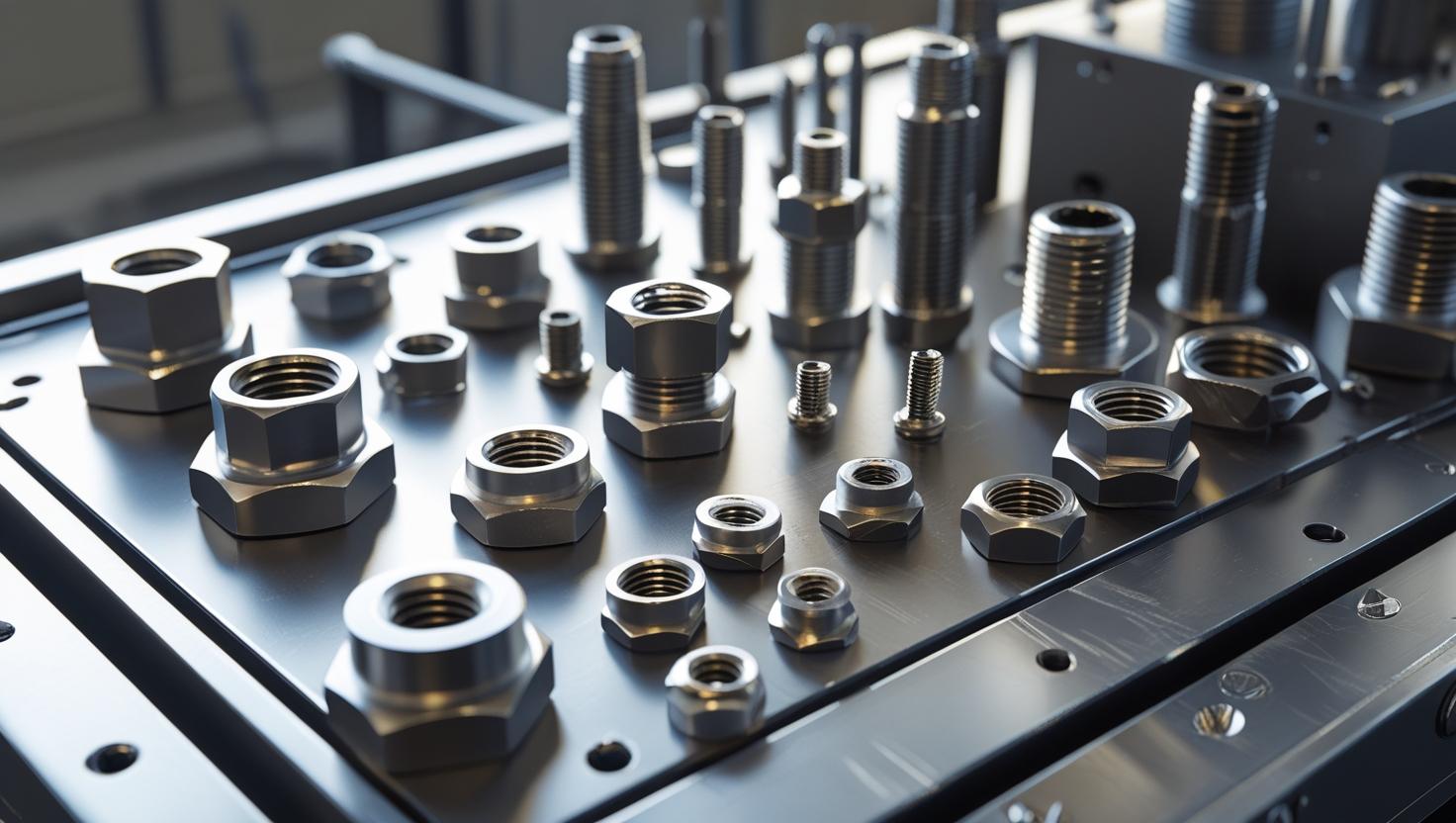

What Are Nut Custom Parts?

Nut custom parts refer to components that are manufactured to non-standard dimensions, materials, or finishes to meet your specific application. This can include:

-

Special thread pitches (UNC/UNF/BSP or metric variants)

-

Uncommon shapes (flange, square, T-nut, wing nuts)

-

Plating and surface treatments (zinc, nickel, Dacromet, black oxide)

-

Materials (A2/A4 stainless, brass, nylon insert, carbon steel)

-

Precision tolerances for aerospace, automotive, or medical industries

Jingle manufactures nut custom parts starting from drawings, CAD specs, or even physical samples—with full support for OEM confidentiality and QC traceability.

How Our Nuts Stand Out from the Rest

When it comes to fasteners, not all nuts are created equal. What makes Jingle’s nut solutions different is our ability to go beyond standard supply:

-

We don’t just sell nuts—we build kits for specific use cases. Whether you’re assembling industrial machinery or packaging aftermarket parts, our nut sets are pre-sorted, labeled, and tested to fit your workflow.

-

Our materials meet industry-specific demands. From A2/A4 stainless steel for corrosion-prone environments to carbon steel with anti-loosening designs for heavy machinery, every nut is chosen based on real engineering needs.

-

We provide true OEM integration. Each nut OEM kit can include customer-specific labeling, multilingual instructions, batch traceability, and export documentation—all tailored to your system or market.

Unlike generic suppliers, we focus on ready-to-use, precision-engineered nut kits that save you time, reduce installation errors, and ensure long-term reliability in critical applications.

Use Cases for Custom Nut Solutions

1. Machinery & Automotive Assembly Lines

Inconsistent torque or mismatched threads in mass assembly can delay production. Using nut custom parts ensures compatibility with fasteners, bearings, or housings.

2. OEM Aftermarket Product Kits

Brands shipping spare parts or repair kits need clear packaging and correct fitment. Nut OEM kits eliminate guesswork for both technicians and end users.

3. Electrical & Solar Mounting Systems

Corrosion resistance and locking design are key. Jingle supplies nylon-insert and stainless steel nuts, pre-packed by mounting type, for solar racking OEMs.

What to Look For in a Custom Nut Supplier

| Criteria | Why It Matters |

|---|---|

| Custom spec capabilities | Thread, plating, material, torque range |

| Low MOQ support | Allows prototyping and small runs |

| OEM packaging | Reduces warehouse handling |

| Export documentation | CO, invoices, labels all prepared |

| Multi-industry experience | Adapts to construction, automotive, or electronics |

Jingle supports projects from sample development to volume delivery, and we also provide test reports, RoHS/REACH compliance, and multilingual labeling if required.

The Bottom Line: Build It Right from the Smallest Part

Nuts may be small, but when mismatched, they cause real problems—downtime, returns, or failed installations. By choosing nut custom parts and OEM nut kits, you get precision, consistency, and efficiency from sourcing to delivery.

At Jingle, we make every nut count.

Contact us for a quote on your custom nut project, or explore our homepage to learn more about our OEM fastener solutions.