How a Structural Fasteners Supplier Delivers OEM Solutions for Non-Standard Demands

The Challenge of Non-Standard Demands

In large-scale construction and infrastructure projects, structural fasteners are rarely one-size-fits-all. Bridges, tunnels, and high-rise buildings often call for non-standard dimensions, unique coatings, or custom load capacities that cannot be found in standard catalogs. For engineers, these demands create a challenge: how to secure parts that not only fit the design but also comply with strict safety codes and environmental conditions.

This is where a professional structural fasteners supplier steps in. Unlike generic distributors, a factory-backed supplier provides OEM flexibility, certified testing, and the ability to scale production without compromising quality.

OEM Solutions from a Factory Partner

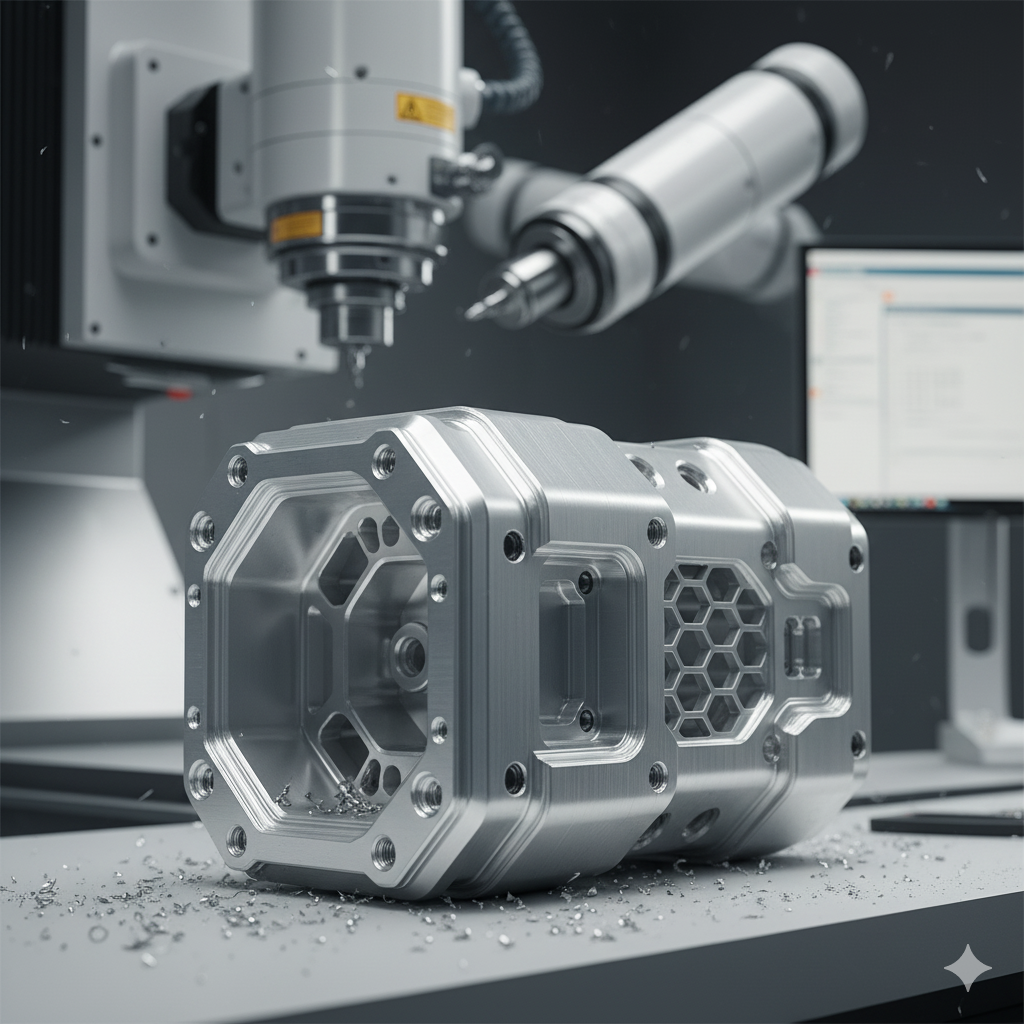

An OEM solution is not simply about making something different—it is about delivering a component that integrates seamlessly into a project’s requirements. A factory-driven supplier like JINGLE transforms drawings into manufacturable parts through CAD/CAM integration, precision machining, and controlled workflows.

The process includes material selection—high-strength steels, stainless alloys, or corrosion-resistant coatings—followed by heat treatments or protective finishes tailored for the operating environment. In-house laboratories then conduct tensile, fatigue, and corrosion tests, ensuring that each batch of fasteners can perform reliably in demanding applications.

With factory direct supply, projects benefit from reduced lead times, consistent specifications, and transparent logistics that align with construction schedules.

Our Advantages as a Structural Fasteners Supplier

At JINGLE, structural fasteners are not treated as generic products but as engineered solutions designed for demanding projects. What sets the factory apart is its ability to combine OEM flexibility, certified quality, and reliable global supply under one system.

-

OEM Customization at Scale: From oversized anchor bolts to corrosion-resistant nuts, JINGLE turns complex engineering drawings into functional fasteners ready for critical applications.

-

Certified Manufacturing Processes: Compliance with ISO, CE, and ASTM standards ensures products meet international construction and safety requirements.

-

Batch Consistency and Traceability: ERP-driven workflows guarantee identical tolerances across thousands of units, with full documentation for audits and project records.

-

Factory Direct Supply: By eliminating intermediaries, JINGLE reduces lead times, controls costs, and delivers fasteners that align with project schedules.

These advantages ensure that JINGLE is not just a structural fasteners supplier, but a long-term partner capable of supporting infrastructure, energy, and industrial projects with reliable, high-performance components.

Real-World Applications of Non-Standard Structural Fasteners

The importance of OEM structural fasteners is evident in industries worldwide:

-

Bridge Construction: Oversized anchor bolts and custom washers designed to handle decades of stress and vibration.

-

High-Rise Buildings: Non-standard fasteners ensuring secure load transfer across steel frameworks.

-

Energy Facilities: Corrosion-resistant fasteners used in turbines, offshore structures, and renewable installations.

-

Heavy Machinery: Customized bolts and nuts capable of withstanding constant vibration and extreme loads.

In these environments, the margin for error is slim, and only a specialized structural fasteners supplier can deliver solutions that match both design intent and operational reality.

From Non-Standard Design to Reliable Supply

The transition from engineering drawings to field-ready components is where many projects face delays. By working with a factory-backed supplier like JINGLE, projects gain access to a seamless workflow—from OEM design support to certified mass production and on-time delivery.

This approach ensures that even when demands are non-standard, the supply is consistent, certified, and ready to support large-scale infrastructure and industrial projects.

Learn more about JINGLE’s OEM structural fasteners solutions on the official website or connect through the contact page.