The Indispensable Role of Fasteners: Understanding the Nut

The world of mechanical assemblies, from the simplest household items to complex industrial machinery, relies on a vast array of components working in concert. Among these, fasteners play a critical role in holding parts together securely. The humble nut is a cornerstone of threaded fastening systems, working in conjunction with a bolt or screw to create a strong, reliable joint. While many types of nuts require tools for tightening, a particularly convenient variant known as the wing nut offers a unique advantage: tool-free operation. This article will delve into the world of nuts, with a specific focus on the design, applications, and technical considerations of the versatile wing nut.

Understanding the Core Function: What is a Nut?

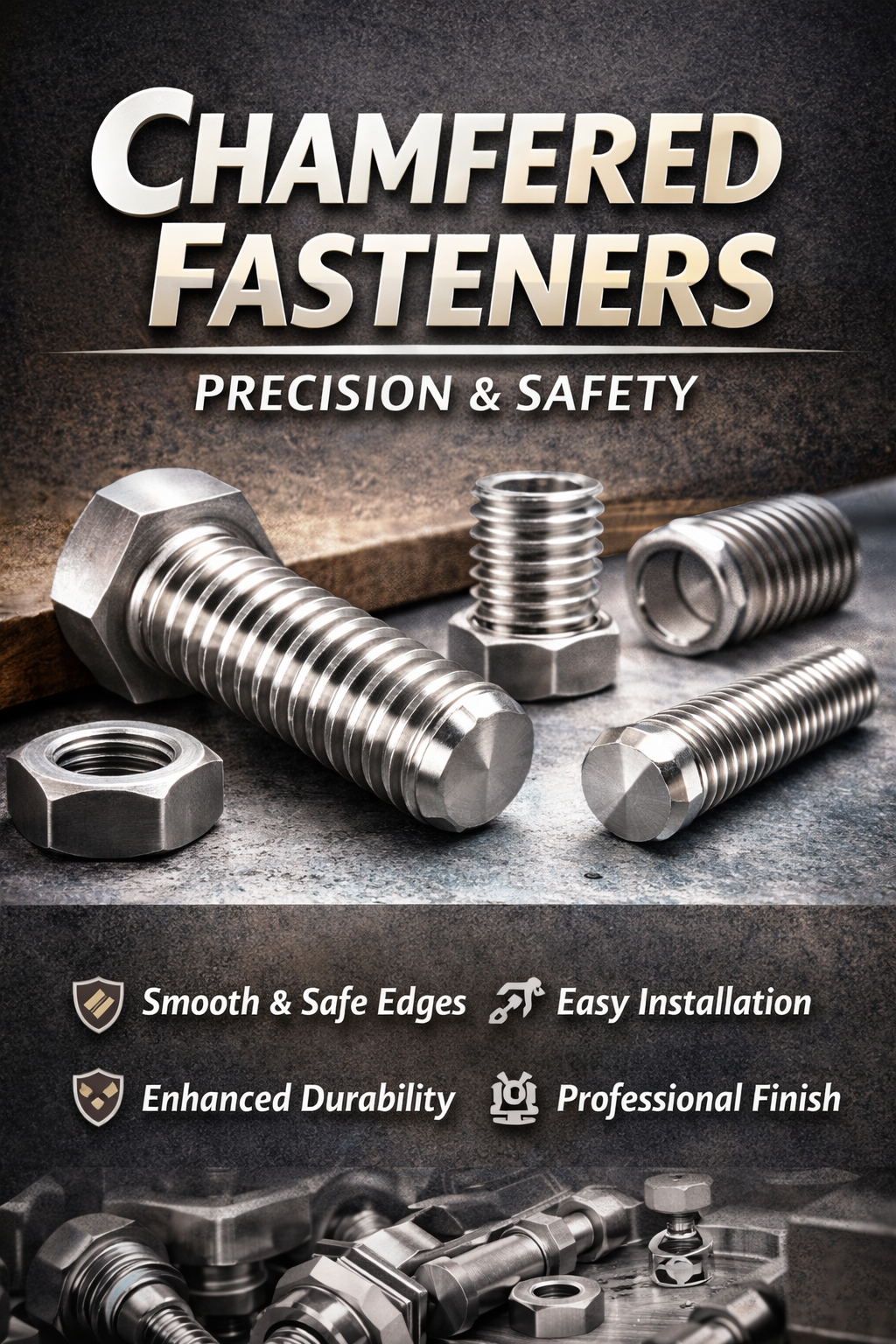

At its core, a nut is a type of fastener with a threaded hole. It is almost always used in conjunction with a mating bolt or screw to fasten multiple parts together. The threads on the nut engage with the external threads of the bolt, and as the nut or bolt is turned, an axial clamping force is generated, drawing the components together. The internal threads of a standard nut are typically right-handed, meaning they tighten in a clockwise direction. The mechanical advantage provided by the inclined plane of the thread converts rotational motion into linear clamping force. Nuts come in a vast array of shapes, sizes, materials, and thread specifications (like UNC, UNF, or metric) to suit diverse engineering requirements and load conditions. The choice of material, such as steel, stainless steel, brass, or nylon, depends heavily on factors like required strength, corrosion resistance, and environmental conditions.

A Closer Look: The Ergonomic Design of the Wing Nut

The wing nut distinguishes itself through its unique design, featuring two "wings" or tabs protruding from opposite sides of the central threaded barrel. These wings serve as finger grips, allowing the user to easily apply torque by hand, without the need for wrenches or other tools. This design is specifically engineered for applications where frequent assembly and disassembly are required, or where access for tools is limited. The mechanism is straightforward: the internal threads of the wing nut engage with the male threads of a bolt or stud. By turning the wings, the user can quickly tighten or loosen the fastener. While they don't achieve the same high torque levels as nuts tightened with tools, they provide sufficient clamping force for many light to medium-duty applications.

Material Considerations for Wing Nut Applications

Wing nuts are manufactured from a variety of materials to suit different performance requirements and environmental exposures. Common materials include:

1. Carbon Steel: Often plated with zinc or other coatings for corrosion resistance, steel wing nuts offer good strength and are cost-effective for general purpose applications.

2. Stainless Steel: Provides excellent corrosion resistance, making it ideal for outdoor, marine, or food-grade applications. Grades like 304 or 316 are common.

3. Brass: Offers good corrosion resistance, particularly against water, and is electrically conductive. It's often chosen for its aesthetic appeal in certain applications.

4. Nylon (Plastic): Lightweight, non-corrosive, and electrically insulating. Nylon wing nuts are suitable for light-duty applications where metal is not desirable, such as in electrical enclosures or where chemical resistance is needed.

The choice of material directly impacts the strength, durability, and suitability of the wing nut for a specific environment and load.

Advantages and Common Uses of the Wing Nut

The primary advantage of the wing nut lies in its convenience and speed of use. The ability to hand-tighten and loosen without tools saves considerable time, especially in scenarios requiring frequent adjustments or dismantling. This makes them invaluable in applications such as drum kits and musical instrument stands for quick setup, bicycle components like quick-release seat clamps, lighting fixtures and stage equipment allowing for rapid reconfiguration, access panels and covers where quick entry is needed, and temporary jigs in workshops. Despite their ease of use, it's important to note that wing nuts are generally not suitable for high-vibration environments or high-torque applications, as they can loosen more easily than a tool-tightened nut. For such scenarios, additional locking mechanisms might be considered.

Choosing the Right Nut for Your Project

Selecting the correct nut for any given application is crucial for ensuring the safety and reliability of the assembled structure. This involves considering several factors beyond just the convenience of manual operation. Key considerations include the required clamping force, the type and size of the thread (e.g., M6, 1/4-20), the material compatibility with the bolt and the components being joined, and the environmental conditions (temperature, moisture, corrosive agents). For critical applications, engineering calculations might be necessary to determine the appropriate size and strength. While a wing style fastener offers significant benefits in certain contexts, it's always important to assess if its mechanical properties align with the demands of the application. If high tensile strength or resistance to significant vibration is paramount, alternatives like hex nuts with locking features, or specialized locking nuts, should be evaluated.

Conclusion: The Enduring Utility of Threaded Fasteners

In the intricate world of mechanical engineering and assembly, fasteners like nuts are fundamental components that ensure structural integrity and functionality. From standard hex-headed varieties that form the backbone of heavy construction to specialized designs catering to unique needs, the diversity is vast. The specific design of the wing-type fastener highlights a thoughtful engineering approach, prioritizing user convenience and speed for applications where frequent adjustments are common and high torque is not the primary concern. Understanding the capabilities and limitations of different fastener types allows engineers, technicians, and DIY enthusiasts alike to make informed choices, leading to more efficient, reliable, and user-friendly designs. The continued evolution and application of various nut designs underscore their indispensable role in modern technology.