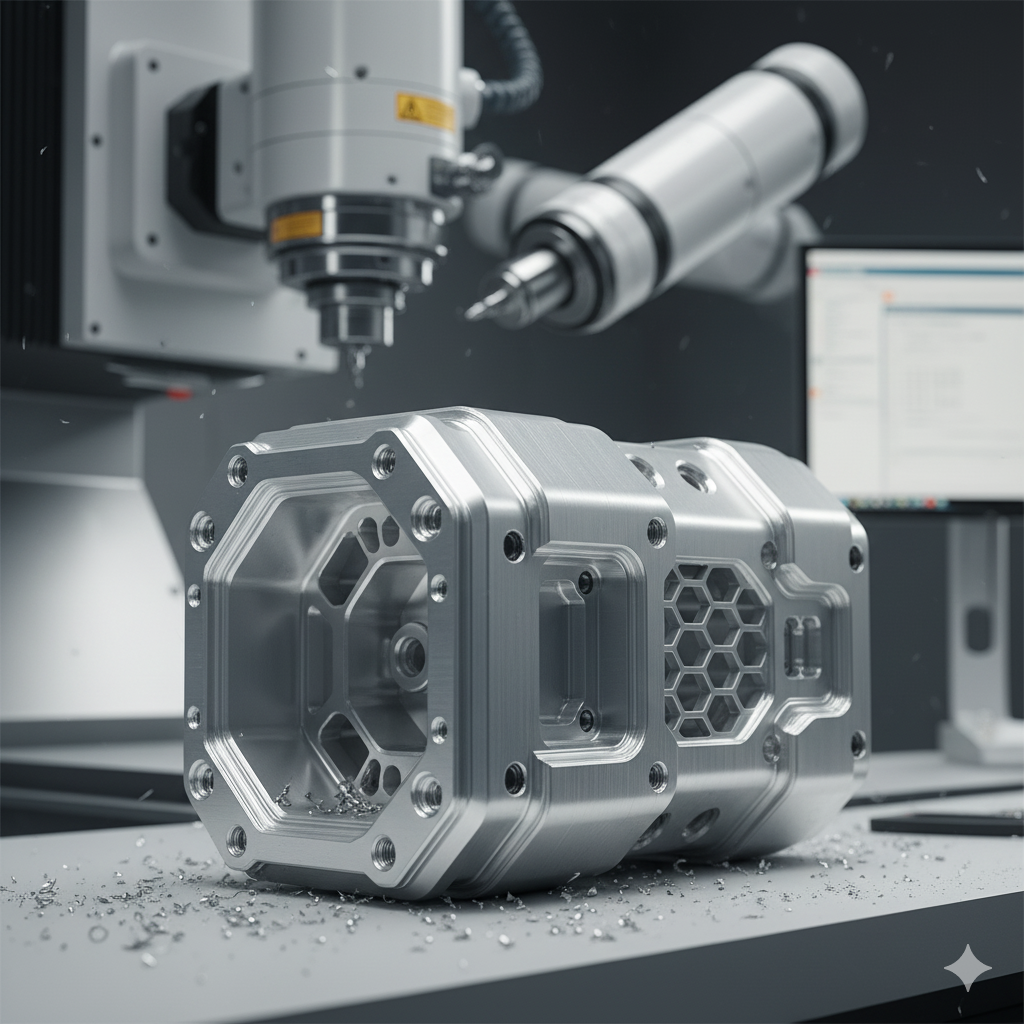

CNC Machined Enclosures for Robotics: Precision Protection and Performance

Protecting Sensitive Robotics Systems with CNC Machined Enclosures

Robotic systems increasingly operate in demanding environments—from factories and warehouses to research labs and healthcare facilities. Protecting sensitive electronics, sensors, and actuators is critical for performance, safety, and longevity.

CNC machined enclosures offer precision protection, enabling:

-

Secure housing of delicate circuits and control boards

-

Shock and vibration resistance in high-movement applications

-

Consistent alignment for modular components and interfaces

For OEM manufacturers, these enclosures support compact, reliable, and customizable designs, ensuring robots perform consistently under operational stresses.

Engineering CNC Enclosures for Precision and Durability

CNC machining expertise enables production of high-precision enclosures tailored to robotic applications. Key engineering advantages include:

-

Dimensional Accuracy: Multi-axis CNC machining delivers tight tolerances, ensuring all components align perfectly and interfaces function reliably.

-

Material Selection: Metals, composites, and alloys can be used to provide lightweight strength, thermal management, and corrosion resistance.

-

Custom Geometry: Enclosures can be tailored for unique robot designs, including integrated cable channels, mounting points, and access panels.

-

Surface Finish and Protection: Anodizing, powder coating, and precise surface treatments enhance durability and wear resistance.

-

Batch Consistency: CNC processes guarantee identical parts across small prototypes and full-scale production, supporting scalable OEM deployment.

Through these engineering practices, CNC machined enclosures ensure that robotic systems maintain optimal performance, even in high-stress or industrial environments.

Tailored Solutions from JINGLE

JINGLE provides OEM CNC enclosure solutions for robotic systems, offering:

-

Custom Design: Enclosures tailored for specific robot models, sensor layouts, or modular systems

-

Certified Quality: ISO and CE-compliant manufacturing ensures enclosures meet global safety and durability standards

-

Material Expertise: Lightweight alloys for mobile robots, robust steel for industrial arms, and specialized composites for sensitive equipment

-

Scalable Production: Rapid prototyping and high-volume CNC machining allow OEM manufacturers to scale without sacrificing precision

-

Integration-Ready: Designed for seamless assembly with electronics, actuators, and mechanical interfaces

JINGLE’s solutions enable robotics OEMs to reduce risk, improve durability, and maintain precise system alignment across their product lines.

Applications of CNC Machined Enclosures in Robotics

CNC machined enclosures are widely used across various robotic applications:

-

Industrial Robots: Protective housings for robotic arms, toolheads, and conveyor-mounted units

-

Service Robots: Compact enclosures for cleaning robots, delivery robots, and healthcare assistants

-

Autonomous Vehicles & Logistics Robots: Precision housings for navigation sensors, motor controllers, and communication modules

-

Research & Laboratory Robotics: Enclosures that support experimental setups while protecting sensitive components

In each scenario, CNC enclosures contribute to mechanical integrity, thermal management, and operational safety, ensuring the robot performs reliably in its intended environment.

Frequently Asked Questions

Q1: Can CNC enclosures be retrofitted to existing robotic systems?

A: Yes. Custom CNC enclosures can be designed for compatibility with legacy and modular robot designs, allowing easy upgrades.

Q2: How do CNC enclosures improve robot longevity?

A: By providing shock resistance, precise alignment, and thermal protection, CNC enclosures reduce mechanical and electrical failures.

Q3: Are CNC machined enclosures suitable for harsh industrial conditions?

A: Absolutely. Material selection and finishing techniques ensure resistance to vibration, dust, moisture, and chemical exposure.

Q4: Can the enclosures be OEM customized for different robot models?

A: Yes. JINGLE provides full OEM customization, including geometry, mounting interfaces, and material selection.

Why CNC Machined Enclosures Matter

CNC machined enclosures are more than protective shells—they enable:

-

Structural Stability: Precise housings protect electronics and sensors under vibration and impact.

-

Thermal Management: Metal and composite enclosures help dissipate heat in high-performance robotics.

-

Design Flexibility: Custom geometries allow integration of sensors, connectors, and actuators while maintaining compact designs.

-

Scalability: OEM-friendly CNC machining allows rapid prototyping and production scaling without quality loss.

By combining precision engineering with material expertise, CNC enclosures from JINGLE ensure that robotic systems operate reliably, safely, and efficiently.

Learn more about JINGLE’s CNC machined enclosures for robotics on the official website or explore custom OEM solutions via the contact page.