The Mechanical Challenges of Modern Agriculture

Agricultural machinery operates in some of the most demanding industrial environments—uneven terrain, abrasive soil, and long operational cycles. Small inaccuracies in components can quickly scale into fuel waste, breakdowns, or missed harvest windows. CNC machining parts, produced with micron-level precision, bring reliability and consistency that traditional fabrication methods cannot guarantee.

For OEM equipment builders, the use of CNC machining parts directly translates into improved operational uptime, reduced warranty claims, and stronger competitiveness in global agricultural markets.

Precision Components That Redefine Farm Equipment Performance

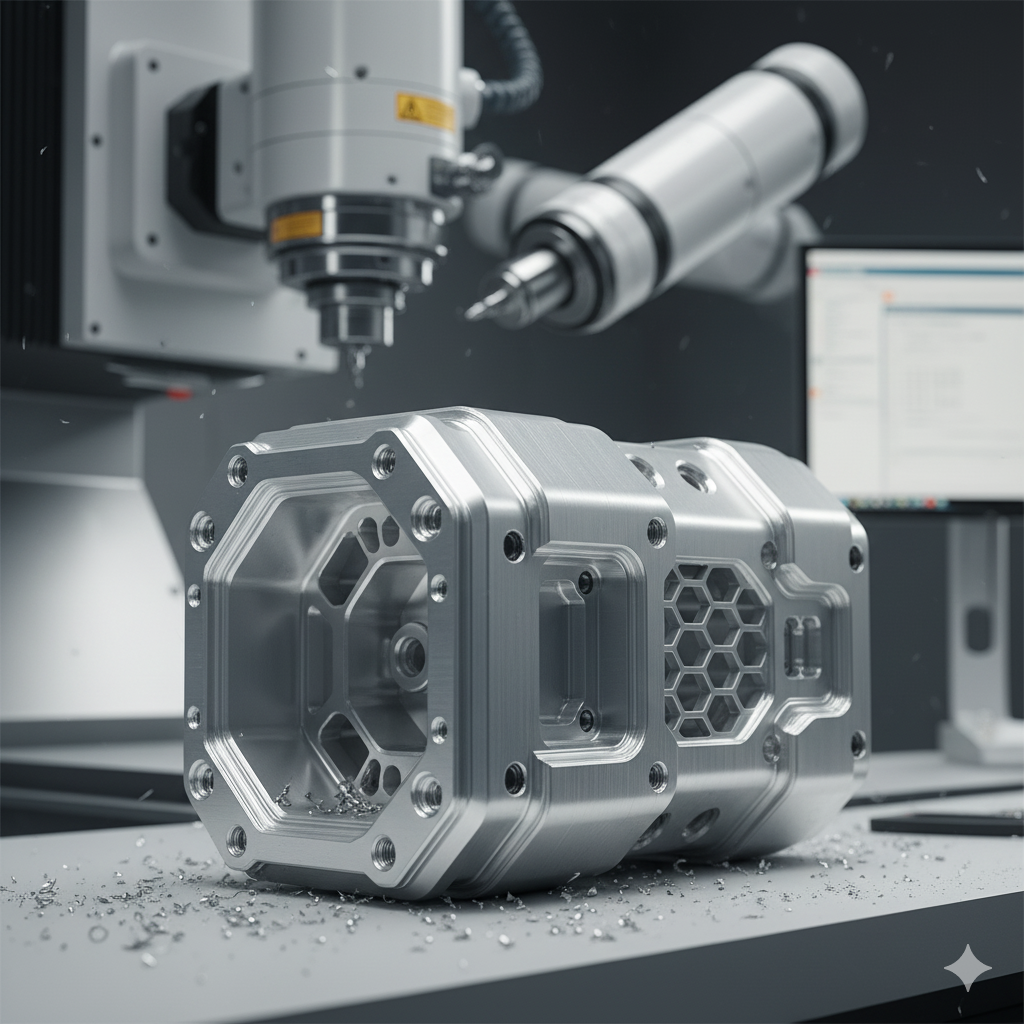

CNC machining is not just about cutting metal—it’s about producing application-specific parts that drive efficiency in agricultural systems:

-

Engines and powertrains – machined pistons, housings, and gears reduce energy losses.

-

Hydraulic controls – precision pump housings and valve blocks ensure consistent pressure for implements.

-

Wear-resistant joints – bushings and couplings designed for abrasive soil contact.

-

Custom fasteners and brackets – OEM parts tailored for compact machinery layouts.

-

Automation-ready parts – components engineered for GPS-guided and smart farming equipment.

Traditional vs. CNC Machined Components in Agriculture

| Aspect | Conventional Parts | CNC Machining Parts (JINGLE OEM) |

|---|---|---|

| Dimensional Accuracy | ±0.2 mm | ±0.01 mm precision |

| Energy Efficiency | Moderate | Optimized geometry for engines |

| Durability in Soil Use | Limited | Coatings & hardened alloys |

| Downtime Frequency | High | Reduced with precision fit |

| OEM Customization | Low | Full design flexibility |

How CNC Machining Translates to Farming Efficiency

By integrating CNC machining parts, agricultural machinery delivers more than durability—it delivers operational efficiency at scale:

-

Fuel savings through optimized combustion and reduced friction.

-

Lower repair costs due to longer-lasting components in high-load areas.

-

Higher uptime during critical planting and harvesting seasons.

-

Improved automation compatibility with precision-ready parts.

-

Sustainability benefits by reducing waste and energy consumption.

These advantages allow manufacturers and farmers alike to build a foundation for smarter, more sustainable agriculture.

JINGLE’s OEM Advantage in Agricultural Components

As a precision machining factory, JINGLE provides OEM agricultural machinery parts that go beyond standard supply:

-

Prototype-to-production scaling for equipment manufacturers testing new models.

-

Material diversity including stainless steel, aluminum, and wear-resistant alloys.

-

Surface engineering with advanced coatings for corrosion and abrasion resistance.

-

Batch consistency ensured through CNC-controlled production processes.

-

Compliance and export readiness with ISO9001 and CE-certified production.

For global agricultural equipment suppliers, partnering with JINGLE means access to a factory that understands field conditions and OEM-specific requirements.

Industry Questions and Practical Answers

Q1: How do CNC machining parts perform in heavy soil and dust exposure?

Specialized coatings and tight tolerances prevent premature wear, keeping components stable under harsh loads.

Q2: Can CNC machining reduce downtime for large-scale harvesters?

Yes. Precision-fit gears, shafts, and hydraulic blocks minimize failures, allowing longer continuous operation.

Q3: Are CNC machining parts adaptable for both tractors and specialized implements?

Absolutely. OEM flexibility ensures compatibility with a wide range of agricultural machinery.

Q4: Do CNC parts contribute to cost savings over time?

Yes. Though initial investment may be higher, lifecycle costs are lower thanks to fuel efficiency, fewer breakdowns, and extended service intervals.

Driving the Future of Agricultural Machinery

Agriculture is shifting toward precision farming and automation, where every component matters. CNC machining parts enable this transition by:

-

Improving energy efficiency in powertrains and hydraulics.

-

Reducing downtime during peak farming operations.

-

Enabling OEM-level customization for global manufacturers.

-

Supporting sustainability by cutting waste and extending equipment life.

By investing in CNC machining parts, agricultural machinery manufacturers ensure their systems are field-ready, globally competitive, and future-proof.

Discover more about JINGLE’s CNC machining solutions for agricultural machinery on the homepage or contact our team directly via the contact page.