The Harsh Reality of Oil & Gas Operations

Oil and gas exploration is one of the toughest industrial sectors. Equipment must withstand:

-

High pressure in drilling and pumping systems.

-

Corrosive environments due to saltwater and chemical exposure.

-

Extreme temperatures, from offshore rigs to desert pipelines.

-

Continuous operation, often 24/7, with little margin for downtime.

In these conditions, generic components fail quickly. CNC machining parts bring precision tolerances and superior material strength, ensuring reliable performance even under severe mechanical and environmental stress.

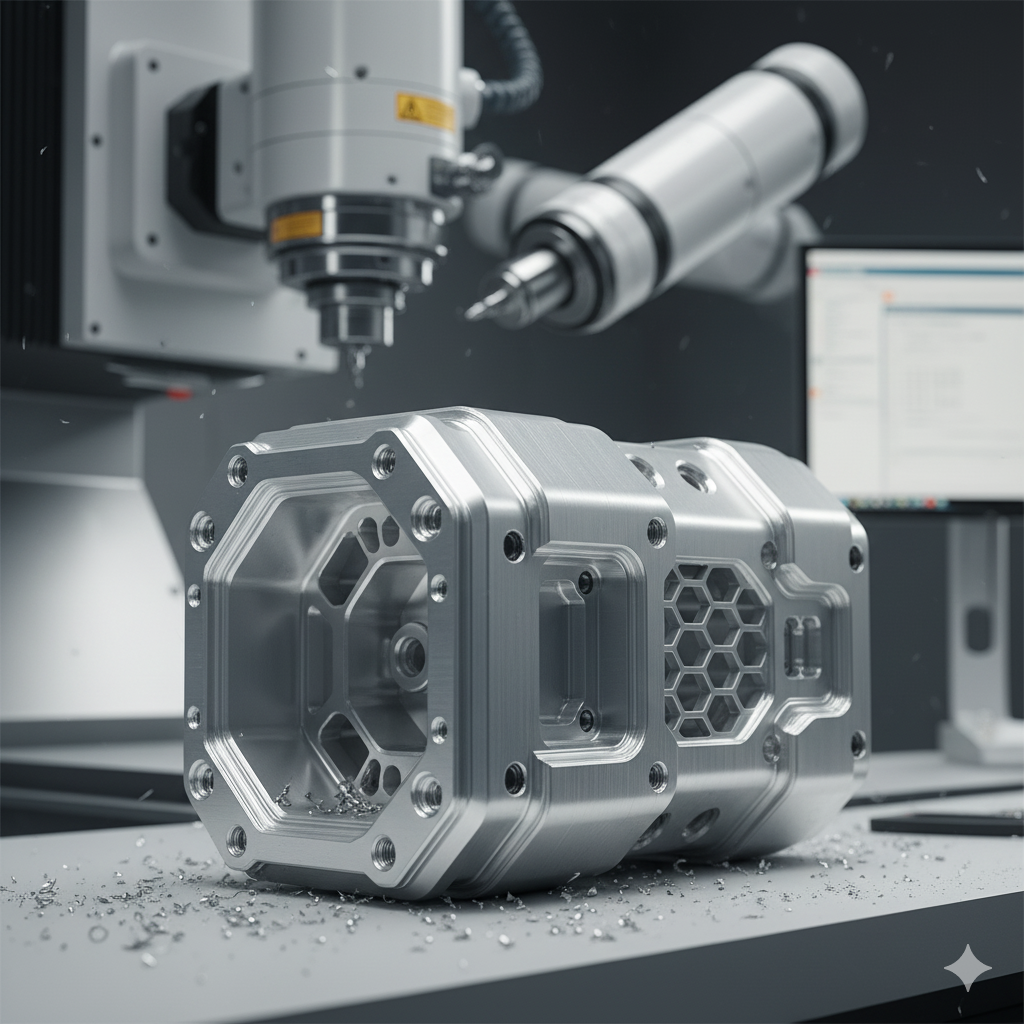

Engineering CNC Parts for Harsh Industrial Use

CNC machining enables the production of parts that meet rigorous oil & gas industry requirements:

-

Valve bodies and pump housings – precision-machined for sealing under pressure.

-

Rotors and shafts – engineered for vibration resistance in drilling equipment.

-

Flanges and couplings – CNC parts designed for leak-free connections in pipelines.

-

Custom fittings – OEM parts tailored for offshore rigs and subsea modules.

-

Corrosion-resistant alloys – including stainless steel, duplex, and Inconel.

📊 Performance Comparison: Standard vs. CNC Machined Oil & Gas Parts

| Feature | Standard Components | CNC Machined Parts (JINGLE OEM) |

|---|---|---|

| Pressure Endurance | Limited | High pressure sealing capability |

| Corrosion Resistance | Basic coating | Advanced alloys + protective finish |

| Dimensional Accuracy | ±0.2 mm | ±0.01 mm precision |

| Service Life | Shorter | Extended under continuous load |

| OEM Customization | Low | Fully customizable |

Application Scenarios in Oil & Gas Equipment

CNC machining parts are essential across the entire oil & gas value chain:

-

Upstream – drilling rigs, rotary systems, and wellhead equipment.

-

Midstream – CNC flanges and couplings in pipelines and pumping stations.

-

Downstream – precision-machined valves and housings in refineries.

-

Offshore platforms – corrosion-resistant CNC parts for subsea applications.

-

LNG systems – precision sealing components for cryogenic conditions.

Each application demands durability against harsh environments, where failure is not an option.

JINGLE’s OEM Factory Capabilities

JINGLE delivers CNC machining parts for oil & gas with a focus on long-term reliability and customization:

-

Prototype-to-mass production tailored for industrial projects.

-

Material expertise covering duplex stainless steel, titanium, and nickel alloys.

-

Batch consistency guaranteed by CNC-controlled quality systems.

-

Surface engineering with anti-corrosion coatings suitable for saltwater and chemical exposure.

-

Global certifications (ISO, CE) ensuring compliance with international oil & gas standards.

By combining precision machining with OEM adaptability, JINGLE positions itself as a strategic supplier for global energy infrastructure.

Common Questions from the Industry

Q1: How do CNC machining parts handle extreme pressure in drilling?

By using precision-engineered geometries and high-strength alloys, parts can seal and endure pressures that exceed standard thresholds.

Q2: Are CNC parts resistant to saltwater corrosion in offshore environments?

Yes. JINGLE uses duplex stainless steel and specialized coatings to extend service life offshore.

Q3: Can OEM CNC parts be adapted for both onshore and offshore systems?

Absolutely. Customization ensures compatibility with diverse installation conditions.

Q4: Do CNC machining parts reduce operational costs?

Yes. Longer component life and fewer failures minimize downtime, directly lowering operating expenses.

Precision That Withstands the Elements

Oil & gas operations demand reliability in the harshest conditions. CNC machining parts deliver:

-

Resistance to pressure, vibration, and heat.

-

Long-lasting performance in corrosive environments.

-

OEM flexibility for different system designs.

-

Global compliance for industrial-scale deployment.

By choosing CNC machining parts, oil & gas operators ensure that equipment remains durable, efficient, and ready for the challenges of tomorrow.

Learn more about JINGLE’s CNC machining solutions for oil & gas equipment on the homepage or connect directly with the team via the contact page.