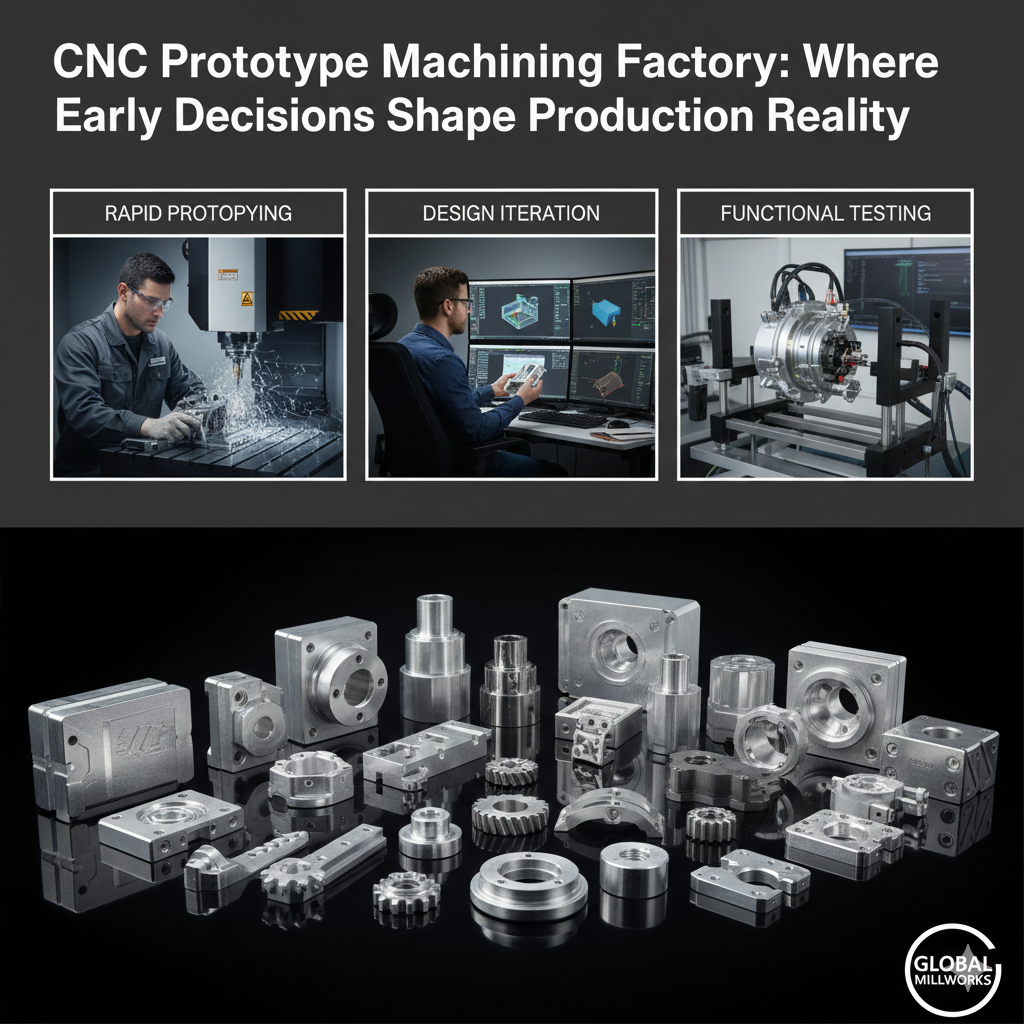

CNC Prototype Machining Factory: Where Early Decisions Shape Production Reality

Prototype machining is often treated as a speed exercise.

Get parts quickly. Check fit. Move on.

In reality, the prototype stage is where most production problems are quietly introduced—or prevented. A CNC prototype machining factory does not just cut early parts; it sets the tone for how designs behave when volumes increase.

That makes prototype machining a risk-filtering stage, not a formality.

Prototype Parts Are Assumptions Made Physical

Every prototype embodies a set of assumptions:

that tolerances interact as expected,

that material behaves predictably,

that features assemble the way drawings suggest.

If these assumptions are wrong, prototype machining is the earliest—and cheapest—place to discover it. Factories that treat prototypes as isolated tasks often miss this opportunity, allowing problems to surface later when correction costs multiply.

Where Prototype Machining Often Goes Wrong

Most prototype failures are not dramatic.

They are subtle—and therefore dangerous.

Common issues include:

-

parts fitting only with manual adjustment

-

features meeting tolerance individually but conflicting together

-

surfaces behaving differently under load or assembly

-

geometry that cannot be fixtured efficiently for production

These issues do not invalidate the design outright, but they signal future production friction.

Why Prototype Strategy Must Reflect Production Reality

Prototype machining that ignores production constraints creates false confidence.

Parts may look correct but rely on setups or sequences that cannot scale.

A capable CNC prototype machining factory evaluates early:

-

whether features can be referenced consistently

-

whether tolerances are achievable without excessive correction

-

whether material removal induces distortion

-

whether inspection methods will scale

This alignment prevents redesign loops later.

Material Choice Matters More at the Prototype Stage Than Expected

Material behavior revealed during prototyping often predicts production risk.

| Material factor | Prototype-stage insight |

|---|---|

| Residual stress | Distortion likelihood |

| Surface response | Functional performance |

| Tool interaction | Wear and finish stability |

| Stock availability | Future supply consistency |

Testing real production materials—rather than substitutes—provides information that drawings alone cannot.

Fixturing Decisions Leave Long Shadows

Prototype fixtures are often temporary.

Their design still matters.

Poor fixture logic may allow a prototype to pass, while hiding alignment problems that reappear in production. Effective prototype machining uses fixtures that mimic production intent, even if simplified.

This approach reveals positional risks early.

Inspection During Prototyping Should Be Selective

Inspecting every dimension wastes time.

Inspecting the wrong ones wastes opportunity.

Effective prototype inspection focuses on features that control:

-

assembly fit

-

load transfer

-

motion or sealing

| Inspection focus | Why it matters |

|---|---|

| Datum relationships | Assembly stability |

| Critical feature interaction | Functional fit |

| Flatness and alignment | Structural behavior |

| Repeat measurement | Early drift detection |

This targeted approach turns prototypes into learning tools.

Prototype Speed Without Feedback Is a Dead End

Fast prototypes without analysis only accelerate mistakes.

What matters is feedback—how machining results inform design decisions.

A CNC prototype machining factory adds value by:

-

highlighting tolerance conflicts

-

suggesting geometry adjustments

-

identifying risky feature combinations

-

documenting lessons for production

Manufacturers such as Jingle treat prototype machining as a collaborative validation step, ensuring insights gained early reduce downstream risk rather than being discarded.

When Prototypes Become Production Liabilities

Projects run into trouble when:

-

prototypes are approved with known adjustments

-

manual fitting becomes normalized

-

undocumented changes accumulate

-

production is expected to “fix” prototype issues

These patterns turn early speed into later delay.

The Role of CNC Prototype Machining in Scaling Projects

Prototyping sits between concept and commitment.

Handled correctly, it reduces uncertainty.

Handled casually, it hides it.

Factories prepared for this role structure prototype work to:

-

anticipate scale-up challenges

-

preserve design intent

-

generate transferable process knowledge

This is where prototype machining becomes an investment, not an expense.

Conclusion: Prototypes Decide More Than They Appear To

CNC prototype machining factories influence far more than early samples. They shape how confidently designs move into production, how predictable quality becomes, and how costly revisions will be later.

The best prototypes do not just fit—they explain why they fit, and whether that fit will last.

To explore CNC prototype machining capabilities and related industrial components, visit the Jingle home page or reach out via the contact page for project-specific discussions and technical support.