Cast-In Plate Anchors for Precast Concrete: What Determines Connection Reliability

In precast concrete construction, connections rarely fail because of insufficient concrete strength.

They fail because loads do not enter the structure the way designers expect.

Cast-in plate anchors sit precisely at that interface. Once embedded, they define how forces move from steel to concrete, how elements align on site, and how tolerant the structure is to construction deviation. Selecting them well reduces uncertainty. Selecting them casually multiplies risk.

Why Cast-In Plate Anchors Are a Structural Commitment

Unlike post-installed anchors, a cast-in plate anchor is fixed the moment concrete cures.

Its position, orientation, weld configuration, and anchorage geometry cannot be corrected without compromising the element itself.

This makes cast-in plate anchors front-loaded decisions. They influence:

-

load transfer paths

-

tolerance during installation

-

long-term crack behavior

-

compatibility with steel connections

Once the panel leaves the factory, the anchor plate either works with the project—or against it.

Where Problems Typically Emerge on Site

Issues with cast-in plate anchors rarely present as immediate failures. More often, they surface as installation friction and unplanned adjustments.

Common site-level problems include:

-

plate misalignment requiring shim stacking or torch correction

-

weld studs inducing local concrete cracking

-

uneven load distribution across the plate surface

-

difficulty achieving flush steel-to-steel contact

Each issue may appear minor in isolation. Together, they increase crane time, inspection overhead, and structural uncertainty—especially in multi-panel assemblies.

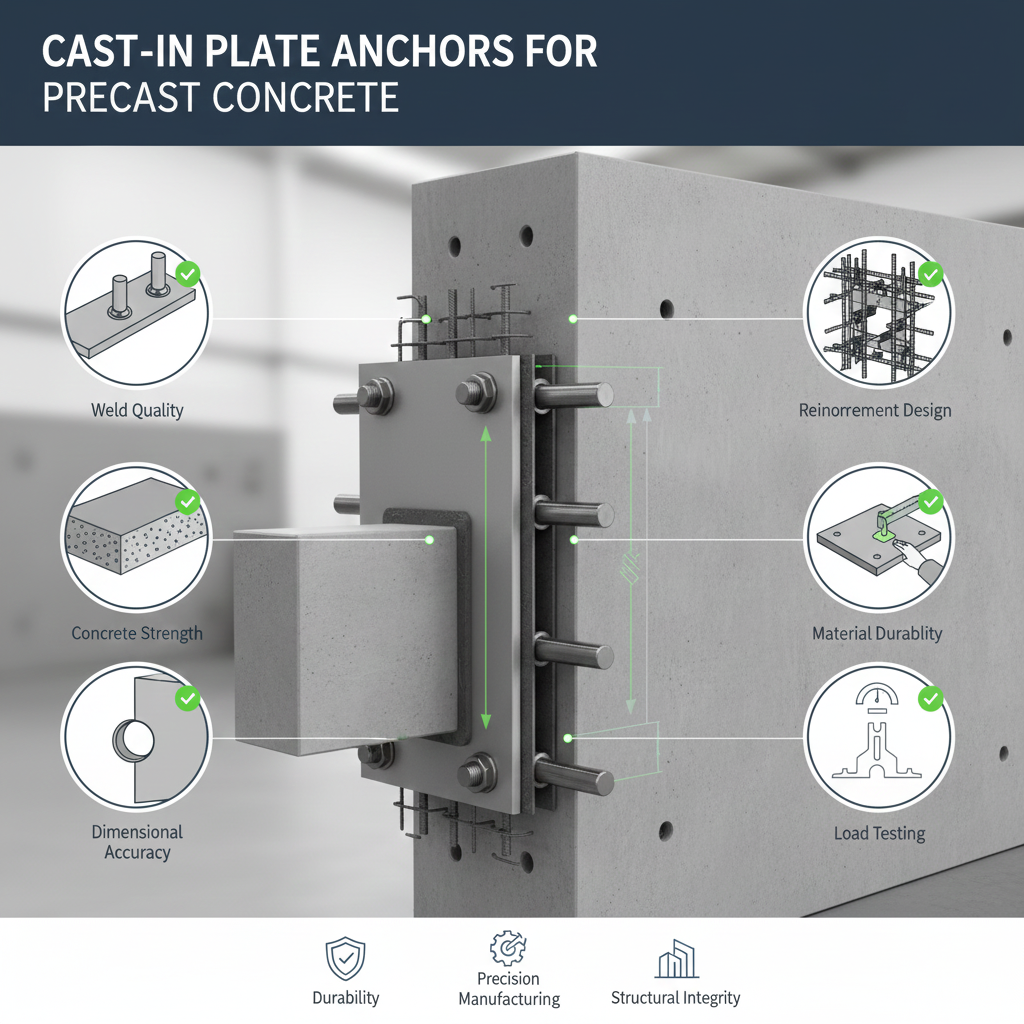

Plate Geometry and Anchorage Design Matter More Than Thickness

It is tempting to evaluate anchor plates by thickness alone.

In reality, geometry governs performance far more than mass.

Key design variables include:

-

plate dimensions relative to edge distance

-

stud layout and embedment depth

-

weld quality between studs and plate

-

interaction with surrounding reinforcement

Anchor plates that distribute load evenly into the concrete core reduce stress concentrations and long-term cracking. Plates that rely on a small number of studs or shallow embedment may satisfy design loads on paper but behave poorly under construction tolerances and dynamic effects.

Material Selection and Surface Treatment in Real Conditions

Material choice affects not only strength but also durability and compatibility with connected steel members.

| Material option | Practical impact |

|---|---|

| Carbon steel | Cost-effective for interior or protected structures |

| Zinc-coated steel | Improved durability in semi-exposed environments |

| Hot-dip galvanized | Preferred where moisture or condensation is expected |

| Stainless steel | Used selectively for aggressive or architectural environments |

Surface condition also influences welding quality and corrosion behavior after installation. Poor surface preparation often leads to site-level welding complications or premature corrosion at the steel–concrete interface.

Manufacturing Quality Is Not Optional

Because cast-in plate anchors are embedded, quality cannot be inspected or corrected later.

Reliable suppliers control:

-

plate flatness and dimensional tolerance

-

stud welding consistency and penetration

-

material traceability

-

alignment fixtures during assembly

Manufacturers such as Jingle treat anchor plate assemblies as structural components rather than generic hardware, verifying weld integrity and load behavior before delivery to precast plants.

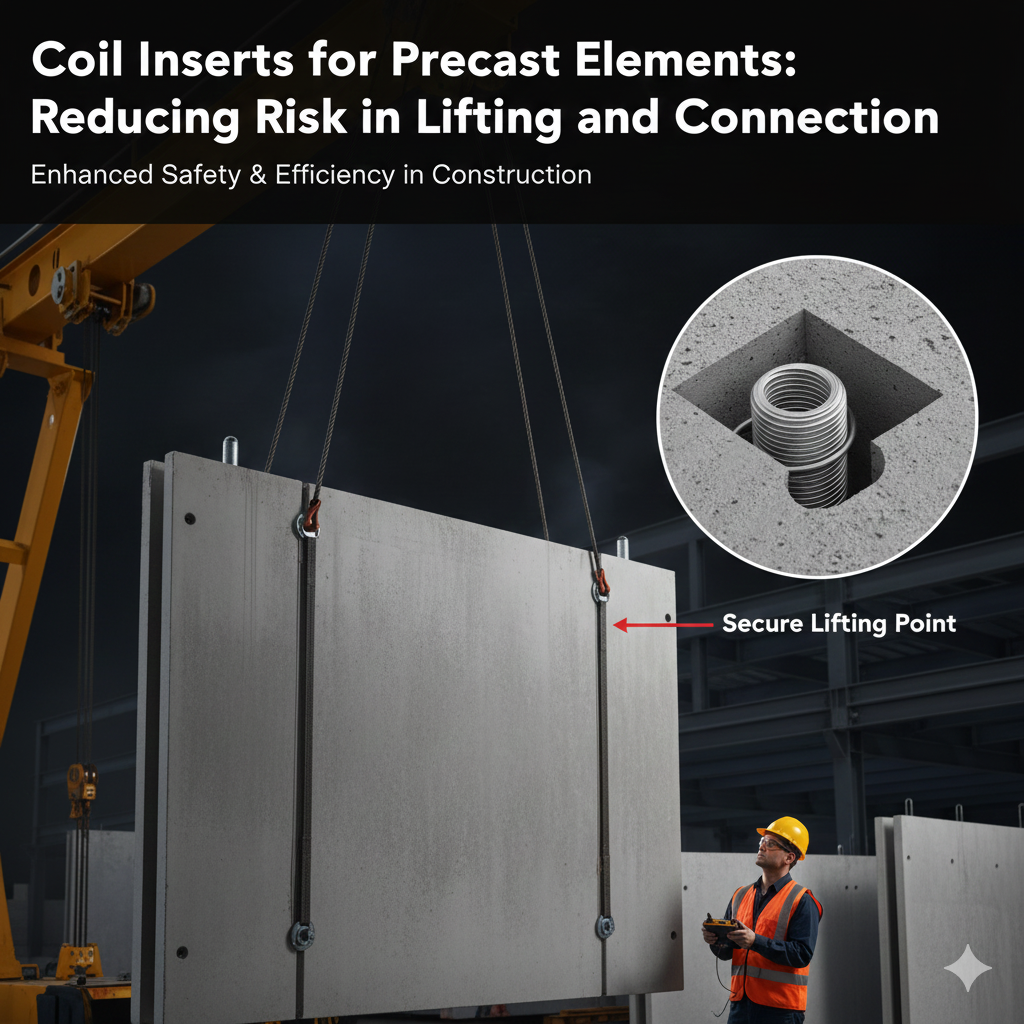

How Cast-In Plate Anchors Affect Installation Efficiency

Well-designed anchor plates simplify installation. Poorly designed ones force improvisation.

Accurate plate positioning allows steel elements to bolt or weld directly without adjustment. Misaligned plates require shims, field welding, or rework—each introducing variability and risk.

In projects with repetitive precast elements, even small misalignments compound quickly, affecting schedule reliability and labor planning.

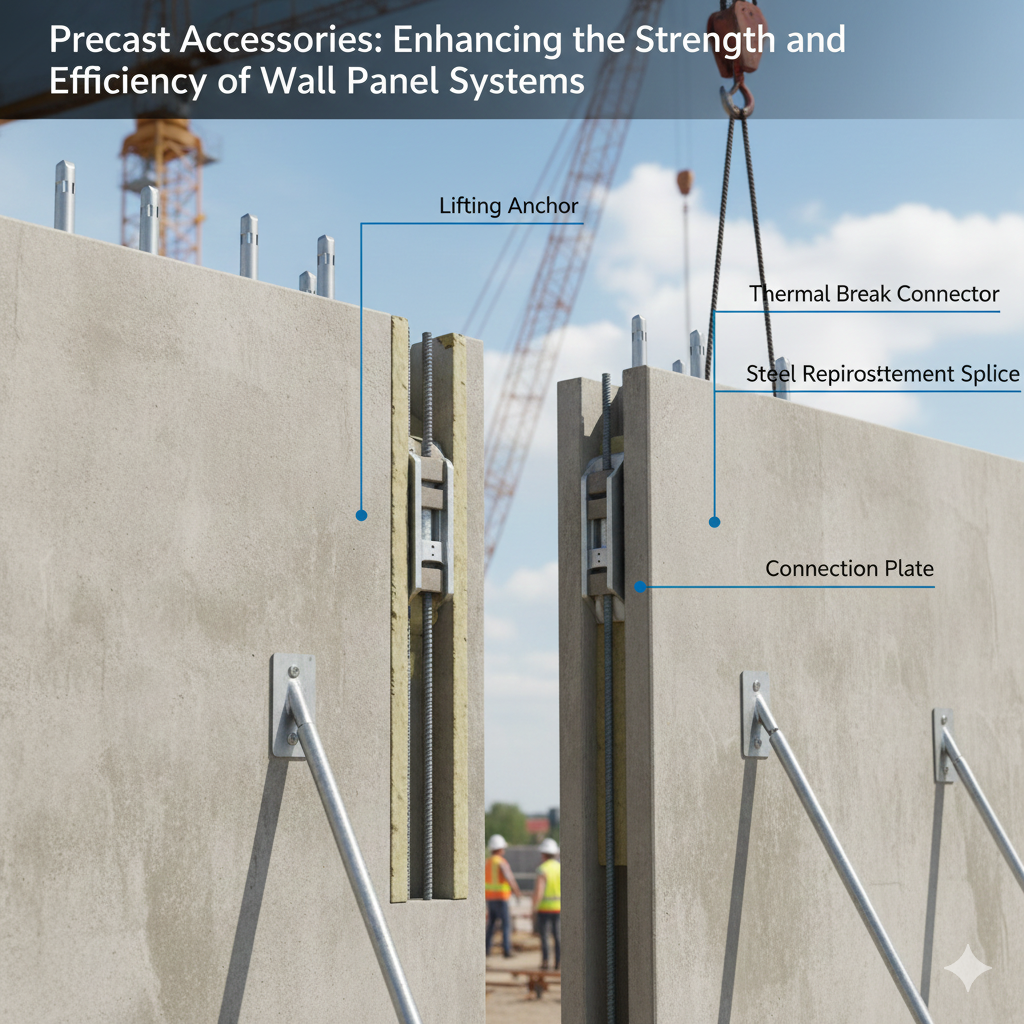

Cast-In Plate Anchors Across the Project Lifecycle

Viewing anchor plates only at installation misses their broader impact.

| Project stage | Role of the anchor plate |

|---|---|

| Casting | Coordinates reinforcement and embedded steel |

| Handling | Maintains structural integrity during lifting |

| Installation | Defines steel-to-concrete alignment |

| Service life | Transfers long-term loads without fatigue |

| Maintenance | Limits corrosion and cracking at interfaces |

This lifecycle influence is why anchor plates deserve the same scrutiny as primary reinforcement design.

Cost Is Hidden in Adjustments, Not Components

Cast-in plate anchors represent a small fraction of total material cost.

Yet they influence some of the most expensive corrective actions on site.

Poor anchor performance leads to:

-

additional welding and inspection

-

extended crane occupation

-

structural tolerancing disputes

-

schedule compression downstream

When evaluated against these risks, investment in well-designed anchor plates functions as risk control, not cost escalation.

Building Predictable Precast Connections

Predictability is the real goal of precast construction.

Cast-in plate anchors contribute to that predictability when their design, material, and manufacturing quality align with real construction conditions—not just drawings.

When chosen carefully, they disappear into the structure.

When chosen poorly, they dominate site discussions.

Embedded Decisions Shape Structural Outcomes

Cast-in plate anchors may be hidden within concrete, but their influence is permanent. They determine how confidently elements connect, how efficiently structures rise, and how reliably loads are transferred over time.

Choosing the right supplier is less about price and more about reducing uncertainty at the most irreversible stage of construction.

To explore embedded anchoring and precast connection solutions, visit the Jingle home page or contact the team through the contact page for technical documentation and application-specific support.