The Role of Micro Fasteners in High-Precision Robotics and Automation

Precision at the Core of Robotics

In high-precision robotics, every micron matters. Robotic arms executing thousands of cycles per hour, or automation lines performing micro-assembly tasks, cannot afford even the slightest instability. Micro fasteners ensure:

-

Alignment in rotating joints where mechanical tolerance is critical.

-

Compact integration for densely packed IoT and sensor modules.

-

Durability under continuous vibration, torque, and thermal variation.

This precision is not decorative—it is the foundation of reliable performance in robotics, factory automation, and medical engineering.

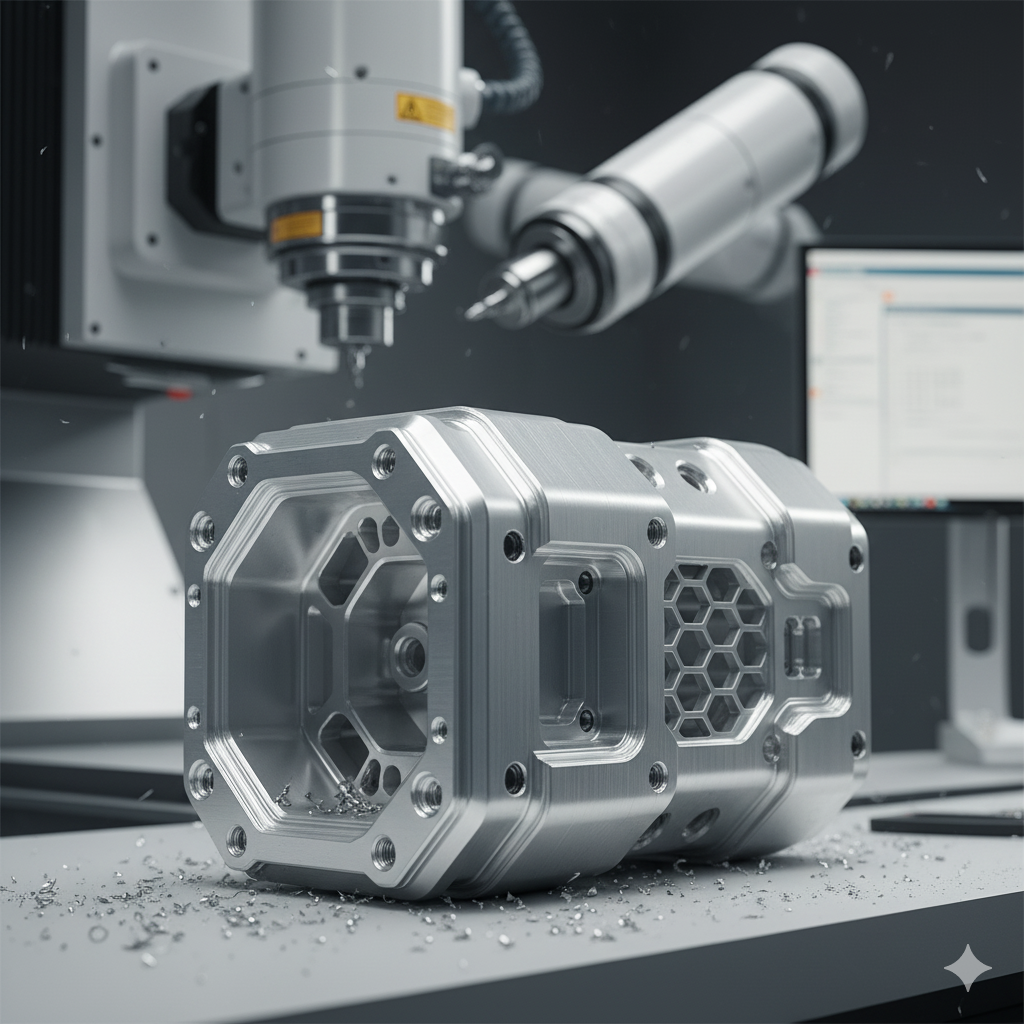

Engineering Micro Fasteners for Extreme Demands

Unlike conventional screws or bolts, micro fasteners used in robotics integrate engineering-grade enhancements:

-

Micro-thread geometries designed for ultra-tight tolerances.

-

High-tensile materials such as stainless steel, titanium, and specialized alloys.

-

Protective coatings that resist chemicals, oils, and sterilization cycles.

-

OEM modularity for compatibility with automation fixtures and robotic tooling.

These engineering refinements transform micro fasteners from “small parts” into strategic enablers of system reliability.

Key Differences Between Generic and Robotics-Grade Micro Fasteners

| Feature | Generic Fasteners | Robotics-Grade Micro Fasteners (JINGLE) |

|---|---|---|

| Tolerance Accuracy | ±0.05 mm | ±0.005 mm micro-level precision |

| Material Endurance | Mild steel | Titanium, high-tensile stainless alloys |

| Vibration Performance | Prone to loosening | Thread-locking micro-engineering |

| Corrosion Resistance | Basic plating | Advanced anti-corrosion surface treatment |

| Assembly Flexibility | Manual only | OEM tooling and modular integration |

Integration in Robotics and Automation Systems

Micro fasteners play roles across multiple automation-critical applications:

-

Robotic joints – stabilizing actuators and bearings for repetitive motion.

-

End-effectors – securing interchangeable grippers and welding tools.

-

Automation chassis – fastening sensor arrays and electronic housings.

-

Medical robotics – sterile, biocompatible fasteners for surgical assistance systems.

-

5G and IoT modules – compact enclosure fastening for high-frequency components.

By enabling lightweight yet stable assemblies, they allow automation systems to achieve higher speed, lower failure rates, and longer service life.

OEM-Driven Solutions from JINGLE

JINGLE addresses industry challenges not just as a factory, but as an OEM partner:

-

Prototyping Support – low-volume runs for R&D in robotics and medical engineering.

-

Scalable Production – high-volume batches with guaranteed tolerance repeatability.

-

Material Flexibility – alloy, titanium, or coated options based on project needs.

-

Compliance Assurance – ISO and CE certified production for global supply chains.

This OEM-focused approach makes JINGLE more than a supplier—it makes the company a strategic partner for next-generation automation projects.

Practical Questions Answered

Q1: How do micro fasteners maintain performance under vibration?

They integrate thread-locking design and optimized geometry, preventing loosening during high-cycle robotic motion.

Q2: Can coatings withstand chemical sterilization in medical robotics?

Yes. Advanced passivation and PVD coatings retain integrity under sterilization and cleanroom conditions.

Q3: Are micro fasteners scalable for both prototypes and mass production?

Absolutely. JINGLE provides small-batch OEM support for prototypes and seamless scale-up for mass production.

Q4: Do micro fasteners increase system costs?

They reduce total costs by minimizing maintenance downtime and extending service life of robotic modules.

Compact Components, Strategic Value

Micro fasteners may be small, but they define the stability and reliability of modern robotics and automation. They:

-

Maintain alignment under thousands of daily cycles.

-

Protect compact electronics in IoT and 5G modules.

-

Enable modular tool changes in automation lines.

-

Scale from prototype to high-volume production.

For robotics and automation projects that demand precision, endurance, and OEM flexibility, JINGLE’s micro fasteners deliver solutions that align with global standards and industry innovation.

Explore JINGLE’s OEM micro fastener solutions on the homepage or connect directly with the team via the contact page.