The Critical Role of Reliable Precast Lifting Anchors in Modern Construction

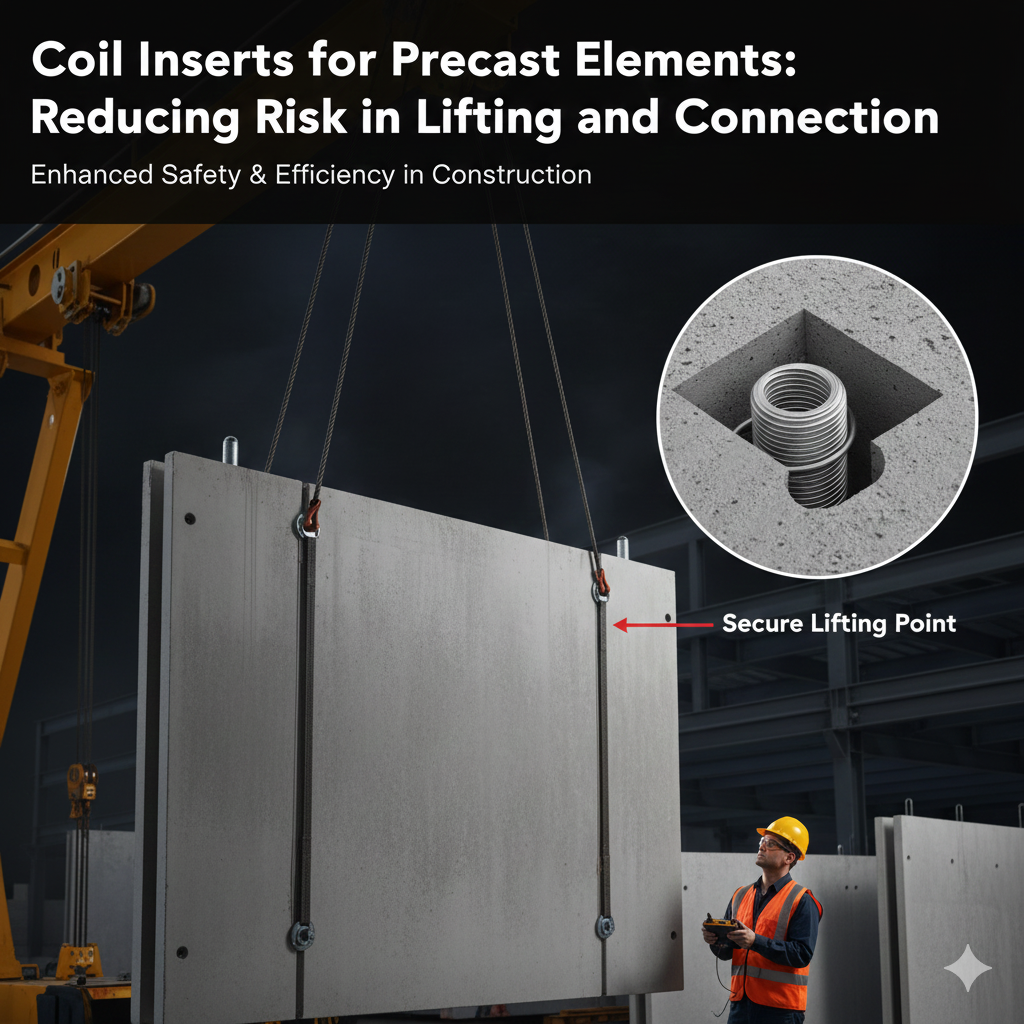

In the fast-paced world of modern construction, precast concrete has become an indispensable material, valued for its efficiency, consistency, and durability. However, the successful implementation of precast elements hinges on the smaller, yet critically important, components used to handle them. At the heart of this process are lifting anchors, the vital connection points that ensure massive concrete panels and structures can be moved safely and accurately from the factory to their final position on site. This is why partnering with a high quality precast lifting anchors manufacturer is not just a matter of procurement, but a fundamental decision that impacts project safety, timelines, and overall success. The integrity of an entire project can depend on the reliability of these small but mighty components, making the choice of supplier a paramount concern for contractors and engineers alike.

Why Sourcing from a Premier Manufacturer Matters

The difference between a standard anchor and one produced by a specialist manufacturer is profound. A reputable supplier invests heavily in material science, engineering, and rigorous quality control protocols. Each anchor is designed and tested to meet or exceed stringent industry standards, ensuring it can handle the specified loads with a significant safety margin. Inferior anchors, often made with substandard materials or inconsistent manufacturing processes, pose a catastrophic risk. A single failure can lead to devastating consequences, including worker injury, damage to materials, significant project delays, and irreparable harm to a company's reputation. Therefore, selecting a high quality precast lifting anchors manufacturer is a direct investment in risk mitigation and operational excellence, providing peace of mind that every lift is secure and reliable.

Unlocking Value with Factory-Direct Sourcing

Beyond the primary concern of quality, construction companies are constantly seeking ways to optimize their budgets without compromising on safety. This is where the advantage of sourcing with a precast concrete accessories factory direct price becomes evident. By bypassing traditional distribution channels and middlemen, companies can acquire superior products at a more competitive cost. This direct relationship with the manufacturer offers more than just financial savings. It facilitates clearer communication, provides direct access to technical support and engineering expertise, and ensures a more transparent supply chain. When you work directly with the source, you have greater confidence in the product's authenticity and a clearer understanding of its production journey, from raw material to finished good. This approach streamlines procurement and adds a layer of assurance that is invaluable in today's competitive market.

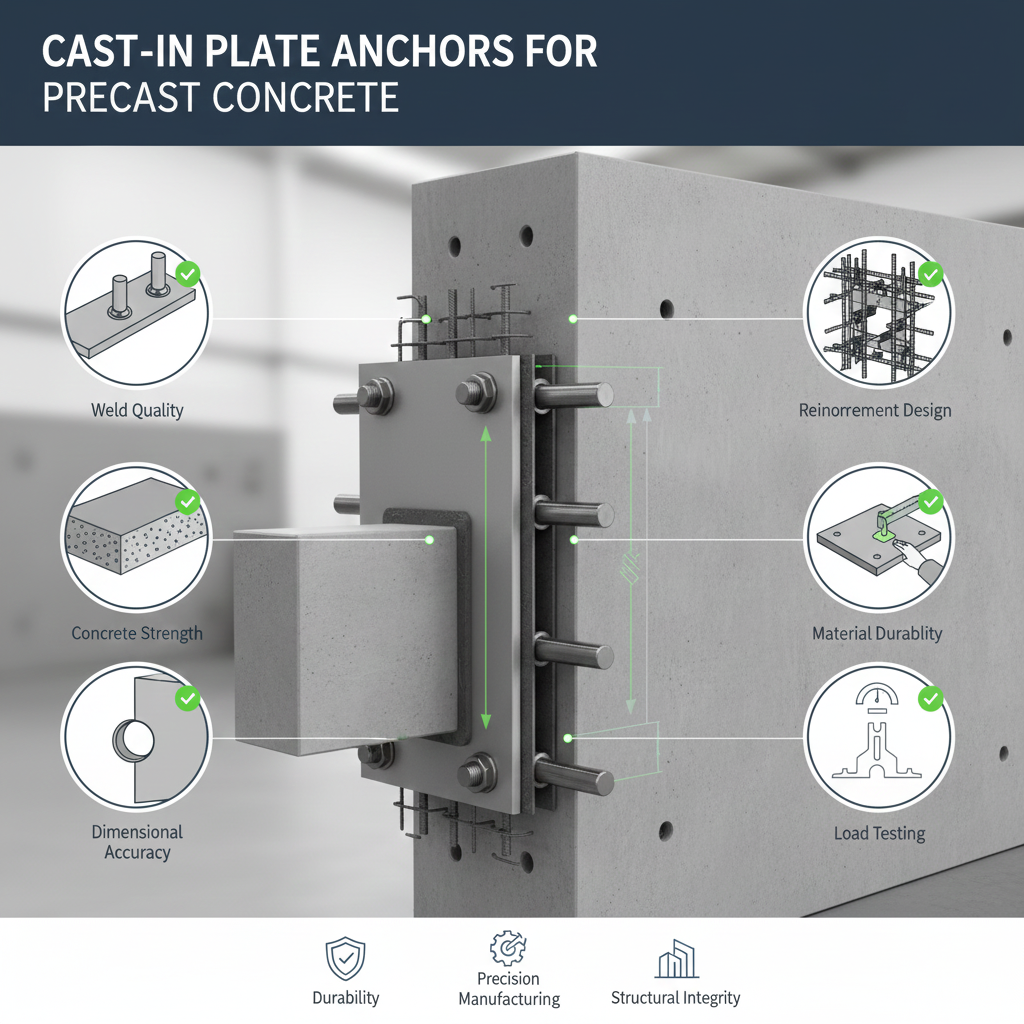

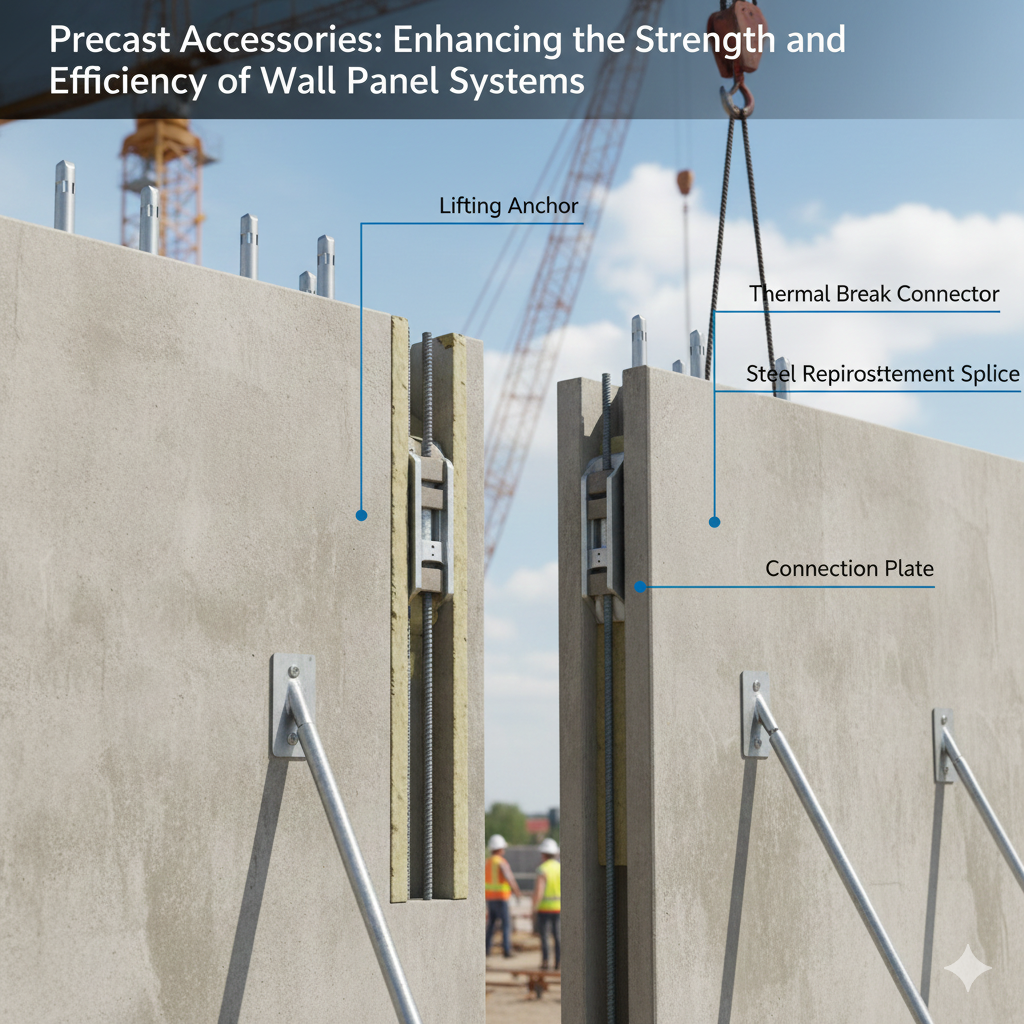

Key Attributes of a Leading Precast Accessories Supplier

When evaluating a potential manufacturing partner, several key attributes distinguish the best from the rest. Look for a company that can demonstrate a clear commitment to quality through certifications like ISO 9001 and provides comprehensive documentation, including load-bearing test results and material traceability reports. A top-tier manufacturer will offer a wide range of lifting systems and accessories to suit various project needs, from spread anchors and spherical head anchors to recess formers and clutches. Furthermore, exceptional customer service is non-negotiable. The right partner acts as more than just a supplier; they provide expert guidance to help you select the optimal solution for your specific application. Securing a precast concrete accessories factory direct price is a significant benefit, but it is most impactful when paired with the unwavering quality and support that a dedicated manufacturer provides. Ultimately, this strategic partnership is the cornerstone of building safer, more efficient, and more profitable projects.