How Precast Accessories Enhance the Strength and Efficiency of Wall Panel Systems

1. The Essential Role of Accessories in Precast Construction

In modern precast concrete production, accessories are more than just connecting parts—they are the foundation of accuracy, speed, and safety.

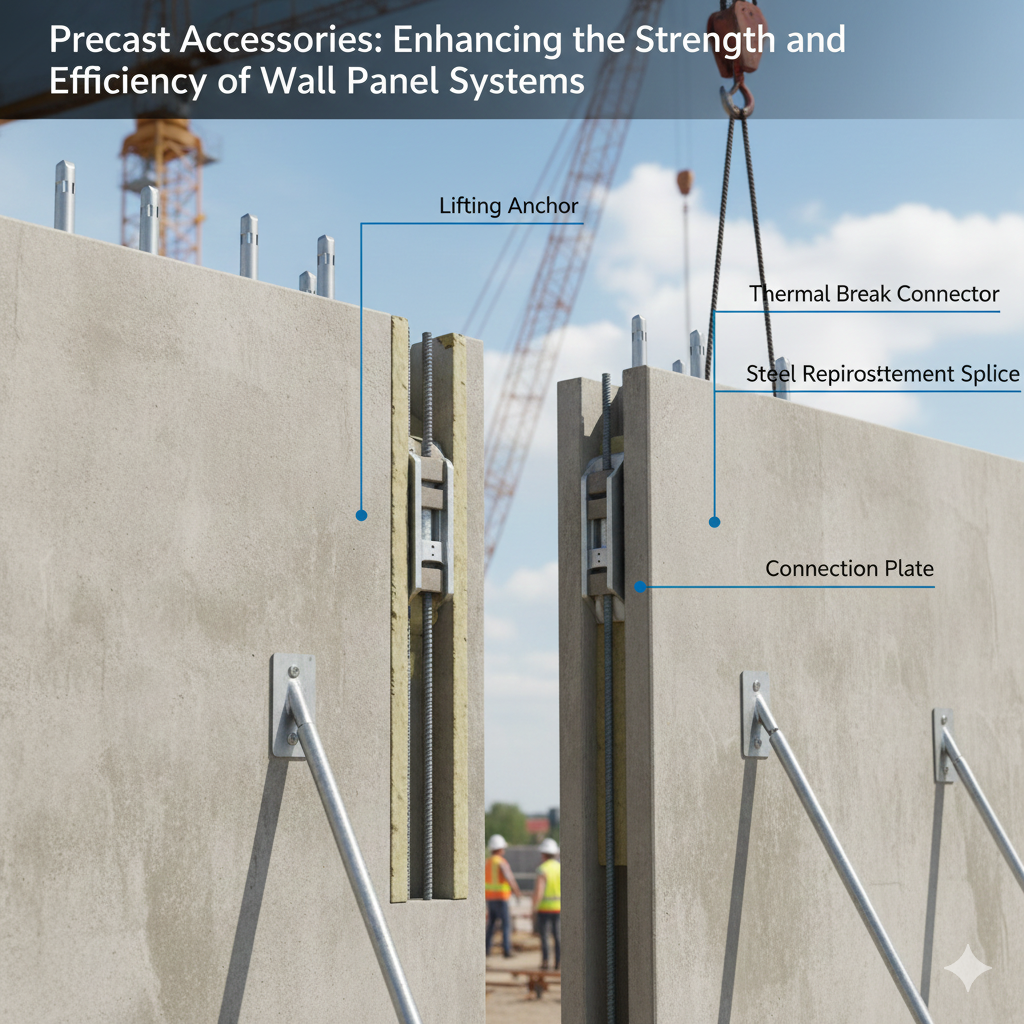

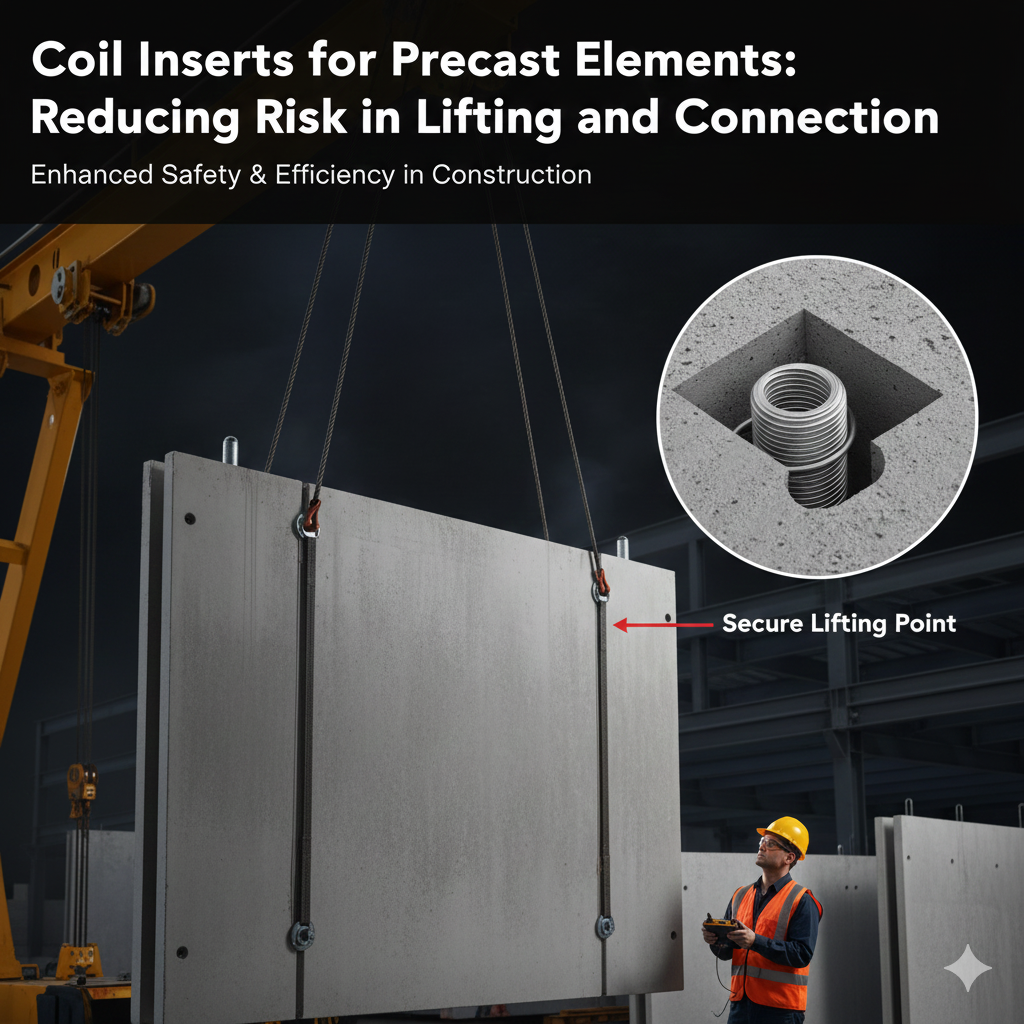

Precast accessories for wall panels include lifting anchors, threaded sockets, connection inserts, and rebar couplers that allow concrete elements to be safely lifted, transported, and installed.

Without these specialized fittings, wall panels would risk misalignment, cracking, or failure under load. High-quality accessories ensure every connection between elements is stable, uniform, and capable of handling the structural stresses of modern architecture.

2. Types of Precast Accessories Used in Wall Panels

Each wall panel demands multiple accessory types to function effectively. The following are the most commonly used categories:

| Accessory Type | Function | Application |

|---|---|---|

| Lifting Anchors | Safely transfer lifting forces during handling | Transport and installation of panels |

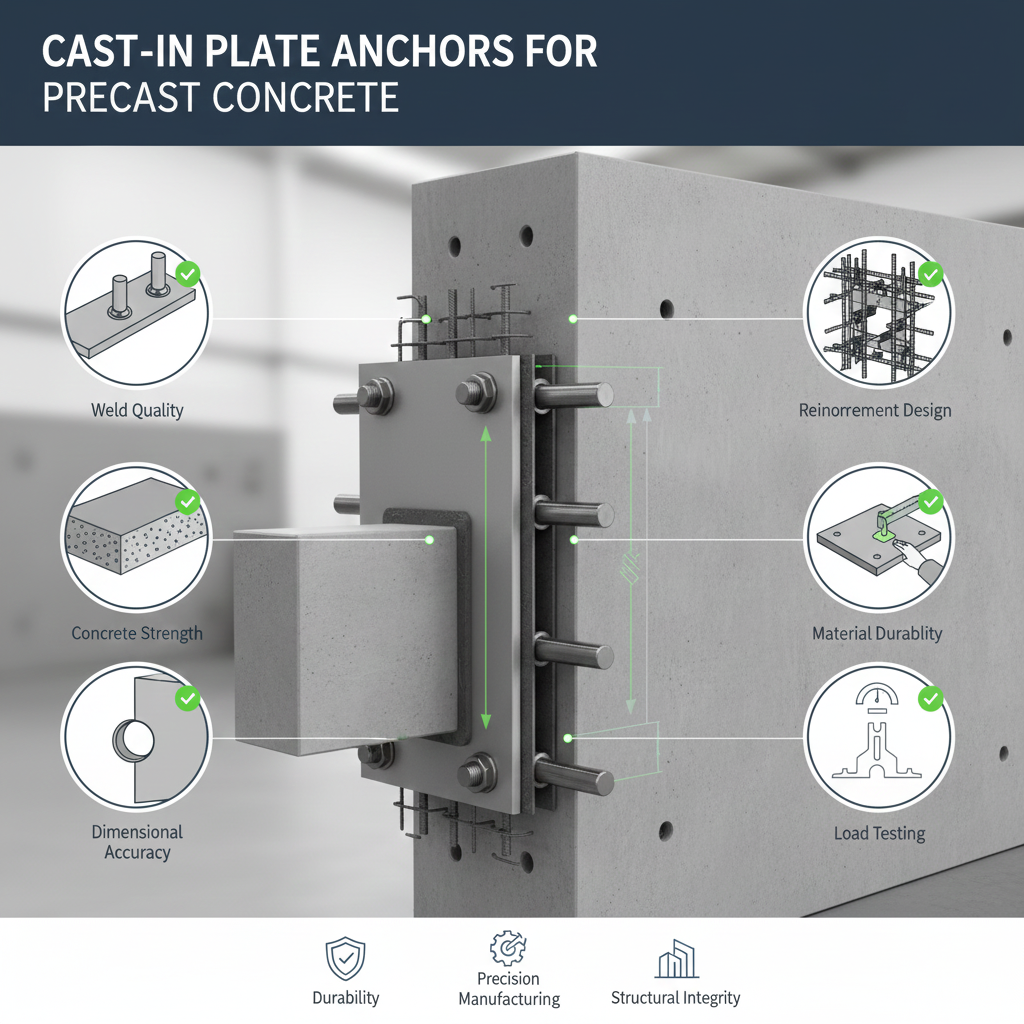

| Threaded Inserts / Sockets | Provide secure mechanical fixing points | Permanent or temporary connections |

| Panel Connectors | Join precast panels together | Structural wall junctions |

| Rebar Anchors & Loops | Reinforce stress areas | Embedded concrete reinforcements |

| Alignment Brackets | Maintain vertical positioning | On-site installation accuracy |

Together, these components transform precast panels from heavy concrete slabs into precisely engineered structural units.

3. Design and Material That Define Durability

The performance of a precast accessory is determined by its geometry, material strength, and surface treatment.

Key design considerations include:

-

Load direction: ensuring anchors resist both tension and shear.

-

Concrete edge distance: preventing spalling or breakout.

-

Reinforcement compatibility: integrating rebar to distribute load effectively.

| Material | Properties | Application |

|---|---|---|

| Carbon Steel | High strength and low cost | Standard lifting anchors |

| Stainless Steel 304 / 316 | Corrosion-resistant | Exterior or marine environments |

| Ductile Iron | High tensile and impact resistance | Heavy precast elements |

| Zinc / Hot-Dip Coating | Surface protection | Long-term outdoor exposure |

Each product is designed with precise tolerances to ensure a perfect fit with embedded hardware during casting and lifting.

4. How Accessories Improve Wall Panel Performance

Precast wall panels must handle multiple load stages—casting, lifting, transportation, and service life.

The right accessories enhance performance at every stage:

-

During lifting: anchors distribute load evenly, preventing stress concentration.

-

During transport: sockets maintain alignment and absorb vibration.

-

During installation: connectors simplify adjustment and ensure vertical precision.

-

In long-term service: stainless and galvanized finishes protect against corrosion, even in humid or coastal conditions.

By combining these mechanical and chemical protections, accessories extend the life and reliability of precast systems while reducing maintenance needs.

5. Manufacturing and Quality Control

High-quality precast accessories require both precision engineering and rigorous testing.

Jingle applies advanced forming and machining methods to produce consistent results:

-

Cold forging and CNC machining for accurate thread geometry.

-

Heat treatment to achieve balanced strength and ductility.

-

Galvanizing or passivation for surface durability.

-

Load testing according to EN 1992-4 and ACI 318 standards.

-

Batch traceability for full project documentation.

Before dispatch, every accessory undergoes visual inspection, tensile testing, and dimensional verification to ensure compliance with design specifications.

6. Real-World Applications Across Construction Sectors

| Sector | Precast Application | Core Requirement |

|---|---|---|

| Residential Buildings | Wall panels and façade elements | Safety and installation speed |

| Commercial Projects | Curtain walls, partitions | Alignment and finish precision |

| Infrastructure | Sound barriers, retaining walls | Shear and pull-out strength |

| Industrial Plants | Heavy-duty wall and floor panels | Load-bearing performance |

| Modular Housing | Prefabricated modules | Fast connection and reusability |

Across these fields, precast accessories bridge design precision with on-site efficiency, making modular construction both faster and safer.

7. Standards and Testing Compliance

To ensure safety and global compatibility, precast accessories must meet strict standards:

-

EN 1992-4 (Eurocode 2): design of anchorages in concrete.

-

ACI 318 (US): building code for concrete structures.

-

ISO 9001 / CE certification: quality and process validation.

-

Salt-spray & fatigue testing: corrosion and load endurance verification.

Compliance with these standards ensures that accessories perform predictably under structural and environmental stress.

8. Key Advantages for Precast Manufacturers and Contractors

| Advantage | Description | Benefit |

|---|---|---|

| Simplified installation | Prefitted lifting and connecting systems | Faster construction |

| Consistent load transfer | Engineered load paths | Reduced risk of cracking |

| Corrosion protection | Hot-dip galvanized or stainless finish | Long-term durability |

| Modular compatibility | Standardized inserts and anchors | Flexible system integration |

| Cost efficiency | Reduced on-site labor | Lower total project cost |

By integrating high-quality accessories, precast factories can streamline production while ensuring each wall panel meets its design load and alignment tolerance.

9. Building Smarter with Reliable Precast Accessories

The strength of a precast wall panel is only as good as the hardware it relies on.

Well-engineered accessories transform concrete from a static material into a modular, adaptable system that meets modern construction demands.

For builders and precast producers, investing in certified accessories means faster assembly, higher precision, and longer-lasting structures.

Explore more fastening and precast hardware solutions at the Jingle Home Page

or reach our technical team through the Contact Page for specification support and project consultation.