How CNC Machining Components Drive Custom OEM Solutions

The Role of CNC Components in OEM Projects

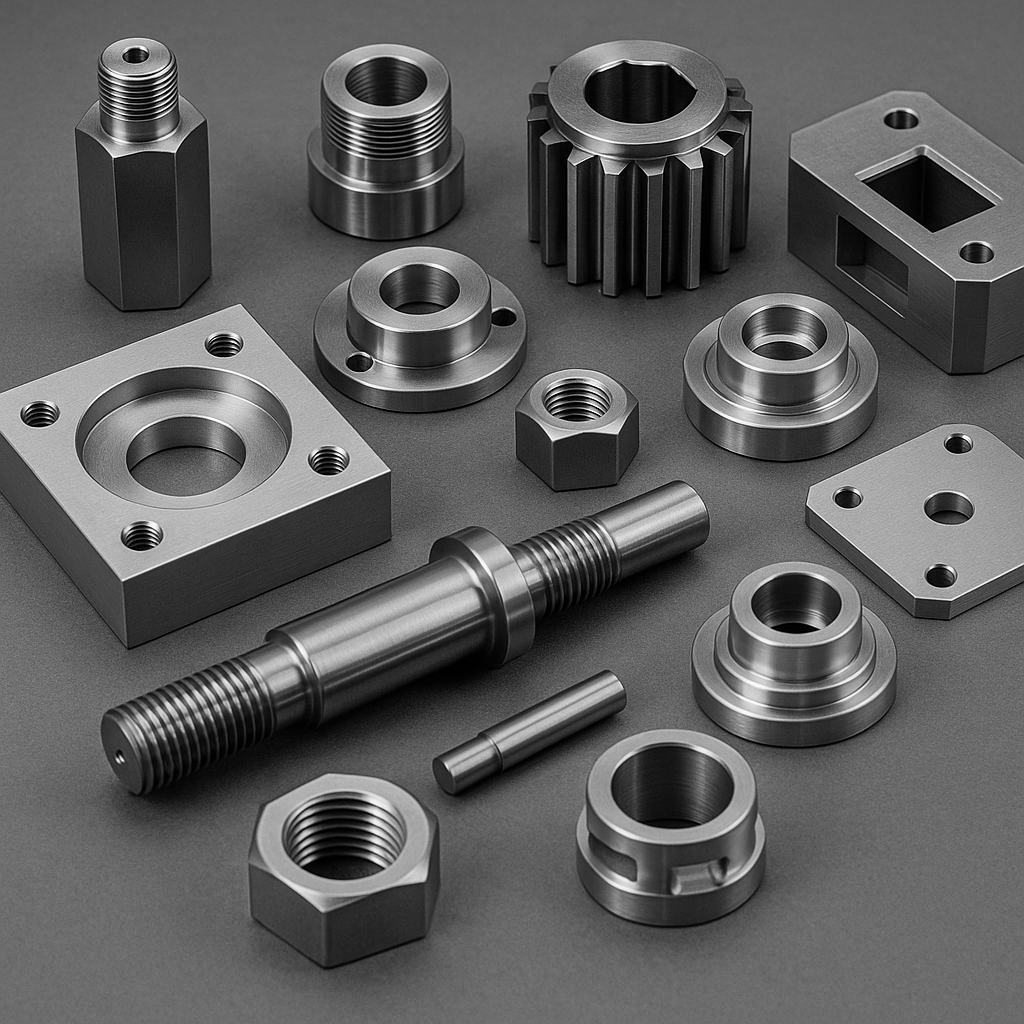

Every OEM project starts with a challenge: creating components that cannot be sourced off the shelf. Whether it is a connector for a medical device, a gear for an automotive system, or a housing for energy equipment, CNC machining components are the bridge between design concepts and real-world performance. Unlike standard catalog fasteners or generic parts, CNC components are engineered to meet the specific tolerances, materials, and finishes that OEM applications demand.

Why CNC Machining Fits OEM Customization

The value of CNC machining for OEM projects lies in its flexibility. With multi-axis machines and advanced programming, factories can produce components with complex geometries and micro-level accuracy. More importantly, CNC machining allows manufacturers to respond to non-standard requirements without compromising on consistency.

For OEM customers, this means:

-

Components designed to exact drawings and prototypes.

-

Ability to use specialized materials such as titanium or high-strength alloys.

-

Surface finishes tailored to the operating environment, from anodizing to PVD coatings.

-

Confidence that prototypes can transition smoothly into scaled production.

This blend of precision and adaptability makes CNC machining the foundation of modern OEM supply chains.

JINGLE’s Approach to OEM CNC Manufacturing

At JINGLE, OEM customization is embedded in the factory process. Projects begin with design collaboration—engineers review customer requirements, suggest improvements, and ensure manufacturability. Once confirmed, CAD/CAM integration translates these designs into machining paths.

From there, production flows through:

-

Advanced Equipment: Multi-axis CNC centers capable of handling complex parts with repeatable accuracy.

-

Material Expertise: Machining stainless steel, aluminum, titanium, and specialized alloys.

-

Surface Engineering: Heat treatments, protective coatings, and polishing for durability and performance.

-

In-House Testing: Dimensional inspections, tensile and fatigue tests, and corrosion simulations under ISO and CE standards.

-

ERP-Managed Workflow: Traceability from raw material to shipment, ensuring consistency across batches.

This factory-level system ensures that OEM requirements are met without sacrificing cost efficiency or scalability.

Industry Applications of Custom CNC Components

The demand for OEM CNC machining components spans multiple industries:

-

Medical Technology: Biocompatible implants, surgical instruments, and housings require exact tolerances and certified finishes.

-

Automotive Engineering: Custom gears, engine housings, and electronic connectors are developed to meet efficiency and safety standards.

-

Energy Systems: Turbine components, pump housings, and structural connectors must endure high loads, corrosion, and fatigue.

-

Heavy Machinery: Shafts, couplings, and brackets demand strength and repeatable performance for continuous operations.

Each of these sectors depends on components that cannot be replaced with generic alternatives. CNC machining delivers the OEM flexibility and certified assurance that critical industries demand.

Scaling Customization Without Compromise

The greatest challenge in OEM supply is scaling customization. Prototypes may meet exact specifications, but the real test is producing thousands of identical units without deviation. This is where JINGLE’s strength lies—bridging the gap between design intent and large-scale delivery.

Through OEM-focused workflows, certified quality systems, and high-capacity production, JINGLE ensures that every batch of CNC machining components is consistent, compliant, and project-ready.

Learn more about JINGLE’s CNC machining OEM solutions on the official website or explore tailored support through the contact page.