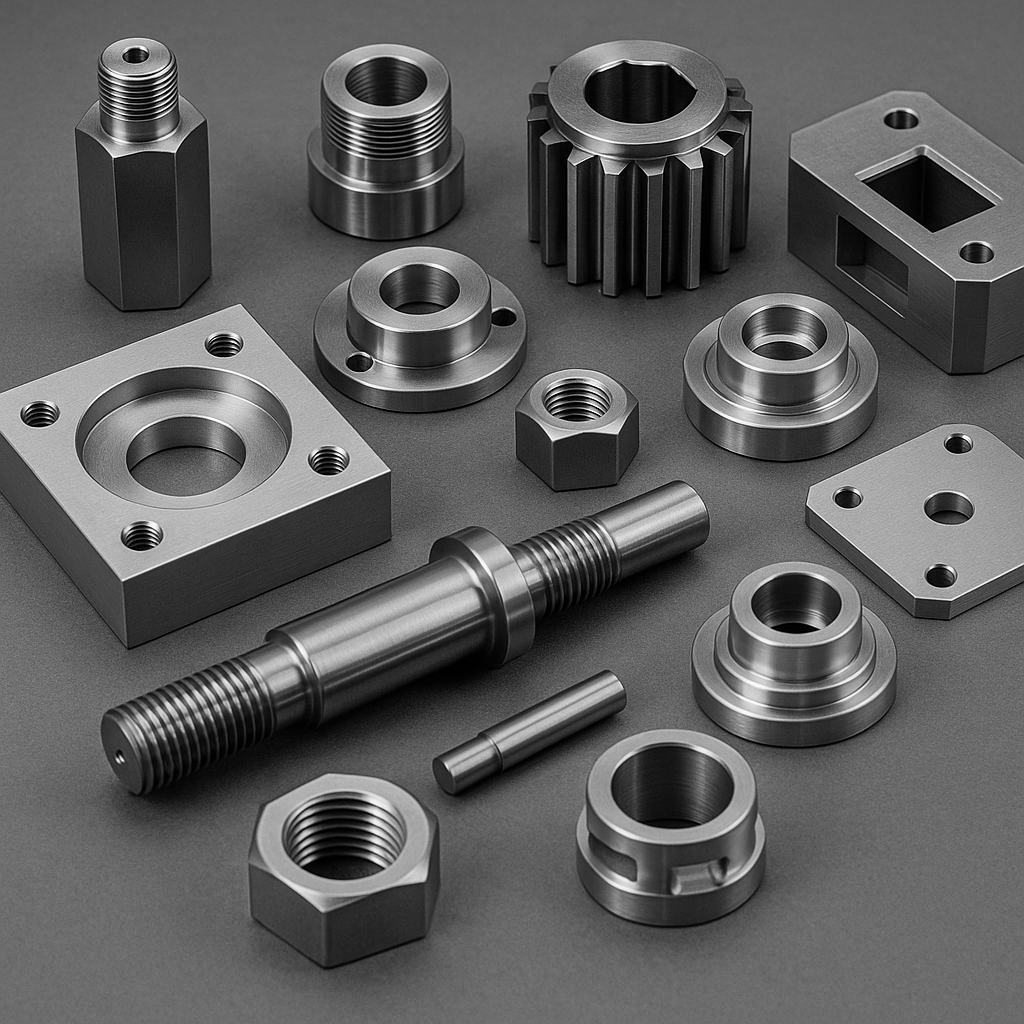

Fastener Factory Direct: Cutting Costs and Securing Quality

Why Factory-Direct Matters in Today’s Supply Chains

Global projects are under increasing pressure to deliver more with less—shorter timelines, stricter budgets, and higher compliance standards. In this context, factory-direct sourcing provides a competitive edge. Traditional distribution often involves multiple intermediaries, each adding cost, uncertainty, and potential for delay. By sourcing directly from a fastener factory, industrial buyers secure better pricing, faster lead times, and consistent quality, with the added confidence that comes from working with a certified manufacturer.

Factory Direct vs. Traditional Distribution

To understand the value of factory direct, it helps to compare it with traditional supply models:

-

Traditional Chain: Manufacturer → Distributor → Sub-distributor → Contractor. Each step adds markup and potential miscommunication.

-

Factory Direct: Manufacturer → Project. Costs are reduced, specifications remain clear, and deliveries are better aligned with schedules.

For construction firms, energy developers, and machinery manufacturers, this streamlined approach means less risk and greater control—particularly in projects where delays or non-compliance can cost millions.

The Advantages of Direct Factory Supply

When choosing a fastener factory direct model, industries gain benefits that go beyond price:

-

Cost Efficiency: Eliminating intermediaries avoids unnecessary markup, ensuring competitive project bids.

-

Certified Quality: Bolts, nuts, rivets, and anchors are delivered with testing documentation that satisfies international standards.

-

OEM Customization: Factories design and manufacture non-standard fasteners, coatings, or head shapes tailored to unique requirements.

-

Batch Consistency: Automated inspection and ERP-driven scheduling ensure identical tolerances across large orders.

-

Reliable Delivery: Direct integration of production with logistics reduces supply uncertainty and prevents schedule disruptions.

This combination explains why global contractors increasingly prefer factory-direct fastener supply.

JINGLE’s Factory-Direct Strength

At JINGLE, factory-direct supply is not just a delivery model—it is a manufacturing ecosystem designed for industrial buyers:

-

OEM Engineering Support – From drawings to prototypes, JINGLE supports contractors developing custom fastening solutions.

-

Large-Scale Production – Capacity to handle bulk orders for bridges, refineries, and industrial facilities.

-

Quality Assurance – Tensile, shear, fatigue, and corrosion testing performed in-house, with ISO and CE certification.

-

Digital Integration – ERP systems connect design, production, testing, and delivery into one traceable workflow.

-

Global Logistics – Factory shipments coordinated to align with multi-phase construction schedules.

This system provides customers with not only fasteners, but confidence in performance, compliance, and timely project delivery.

Applications Where Factory Direct Adds Value

The value of factory-direct sourcing is best understood through its applications:

-

Construction and Infrastructure: Bolts and rivets for bridges, high-rises, and industrial facilities delivered at scale with compliance documents.

-

Energy Projects: Fasteners for wind turbines, refineries, and pipelines require coatings and fatigue testing available only from certified factories.

-

Heavy Machinery: Equipment assembly lines benefit from bulk, consistent fastener supply without quality variation.

-

OEM Product Development: Brands creating new machines or systems need custom-designed fasteners delivered directly from the factory floor.

Each of these scenarios highlights how factory-direct supply reduces cost and risk while improving quality and delivery assurance.

Building Stronger Projects with Factory Direct Supply

Factory direct sourcing is about more than saving money—it is about ensuring structural integrity and project continuity. By partnering with a fastener factory, buyers secure OEM flexibility, certified quality, and logistics that align with project demands.

With its global-scale production, testing laboratories, and ERP-driven delivery, JINGLE positions itself as a factory-direct partner trusted in construction, energy, and industrial projects worldwide.

Learn more about JINGLE’s factory-direct fastener supply on the official website or explore project-specific solutions via the contact page.