Precision CNC Parts: From Micro-Tolerances to Industrial Scale

Precision as the Foundation of Modern Engineering

In today’s industrial landscape, precision is no longer a luxury—it is a necessity. Components that once could tolerate minor variations are now required to perform flawlessly under demanding conditions. Precision CNC parts embody this evolution, offering accuracy down to the micron level. In aerospace, a single misaligned bracket can compromise safety. In medical devices, an imperfect surface finish can affect biocompatibility. Across industries, precision CNC parts are the invisible backbone that ensures systems function seamlessly, safely, and efficiently.

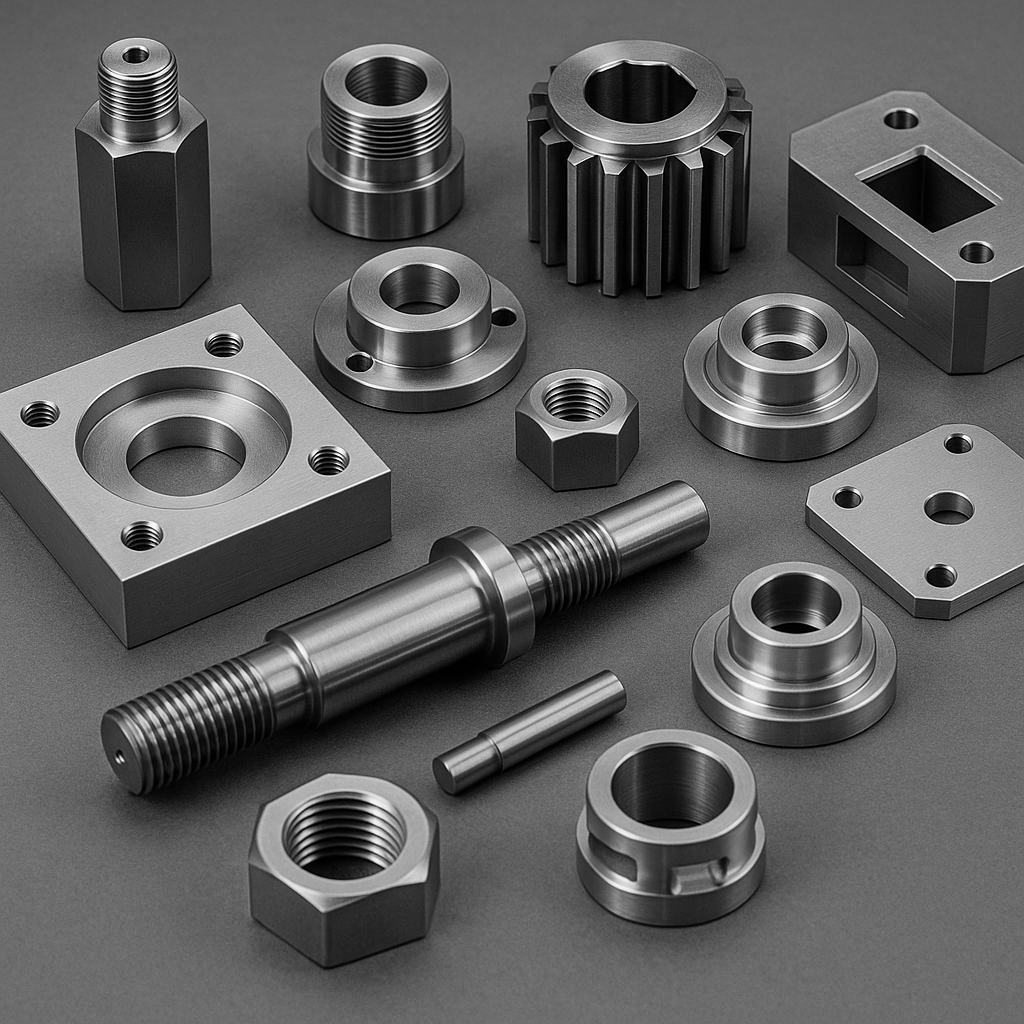

What Makes Precision CNC Parts Distinct

Precision CNC parts stand apart not because of their shape, but because of the strict standards behind their manufacture. A part milled from stainless steel is not valuable simply for the material—it is the tight tolerance, surface finish, and dimensional repeatability that make it indispensable. Unlike standard machined parts, these components undergo carefully planned machining strategies, quality control, and certification processes. Every element, from thread geometry to heat treatment, is optimized to ensure that when thousands of identical pieces are produced, each performs exactly as designed.

Inside the Factory: How JINGLE Ensures Precision

At JINGLE, precision CNC parts are not treated as commodities; they are engineered solutions built through an integrated factory system. The process begins with collaboration—engineers work with project teams to adapt designs into manufacturable forms, using CAD/CAM systems that translate complexity into achievable machining paths. Multi-axis CNC machines then execute these plans, producing intricate geometries with repeatable accuracy.

The story doesn’t end at machining. Surface engineering is applied to match the operating environment: anodizing for corrosion protection, coatings to reduce friction, or polishing for medical-grade smoothness. Each batch then passes through rigorous in-house testing. Dimensional checks confirm tolerances, tensile and fatigue tests verify strength, and corrosion chambers simulate years of environmental exposure. Finally, ERP-driven workflows ensure that this quality is maintained across bulk production, allowing prototypes and large-volume orders to flow through the same controlled system.

JINGLE’s Competitive Advantage in CNC Manufacturing

Factories are not equal, and what sets JINGLE apart is its ability to scale precision. While workshops can achieve accuracy in single prototypes, JINGLE ensures the same standard across thousands of components. This is possible through:

-

OEM Flexibility: Developing parts tailored to specific applications, from gears and shafts to housings and connectors.

-

Certified Assurance: Compliance with ISO, CE, and ASTM frameworks ensures global acceptance.

-

Production Scale: Annual output designed for both small specialty runs and international supply chains.

-

Integrated Supply: ERP-managed logistics reduce delays, aligning delivery with construction or assembly schedules.

This approach turns JINGLE into not just a factory, but a long-term partner that supports industries where downtime or failure cannot be tolerated.

Real-World Applications of Precision CNC Parts

The versatility of precision CNC parts is visible in industries that demand accuracy and reliability: aerospace relies on titanium brackets and structural components capable of withstanding vibration and stress; medical device manufacturers specify stainless steel and biocompatible alloys for surgical tools and implants; automotive companies require gears and housings that endure constant temperature shifts and mechanical fatigue; energy developers use precision-machined connectors and pump housings in turbines and refineries.

Each sector demonstrates that precision CNC parts are not interchangeable commodities. Instead, they are critical enablers of safety, performance, and compliance in systems that shape modern life.

Scaling Precision for Global Projects

Precision is only meaningful if it can be reproduced consistently. A CNC part that is perfect in a prototype but inconsistent in production offers little value to large projects. The true test of a precision CNC factory is the ability to scale accuracy, ensuring every unit in a batch of thousands meets the same stringent criteria. This consistency is what allows aerospace engineers to trust flight components, or contractors to specify parts for multi-phase infrastructure projects.

At JINGLE, this promise is delivered through OEM flexibility, certified testing, and large-scale production capacity. Every component shipped is more than a part—it is a guarantee of long-term reliability.

Learn more about JINGLE’s precision CNC manufacturing capabilities on the official website or connect directly via the contact page.