Understanding Concrete Threaded Inserts

Concrete threaded inserts are indispensable components in modern construction and industrial applications, providing robust and reliable anchoring points in concrete structures. These clever fasteners are designed to be embedded within concrete, creating a female threaded socket that allows for the secure attachment of various fixtures, equipment, or structural elements using standard bolts or threaded rods. Their versatility and strength make them a preferred choice for projects requiring durable connections, ensuring stability and longevity for everything from heavy machinery to delicate installations. The ability to create a strong, reusable threaded connection point within a solid concrete base revolutionizes how attachments are made, offering both temporary and permanent solutions.

Exploring Different Types of Threaded Inserts for Concrete

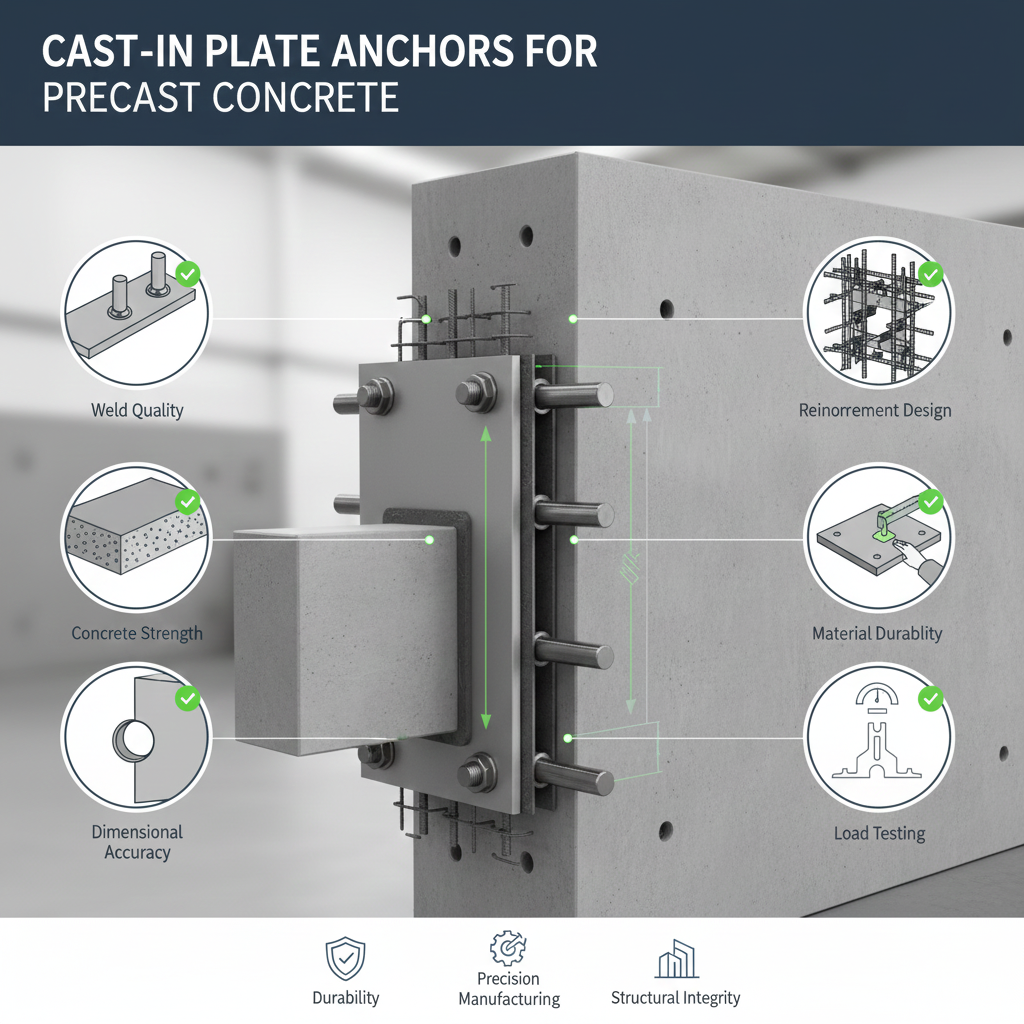

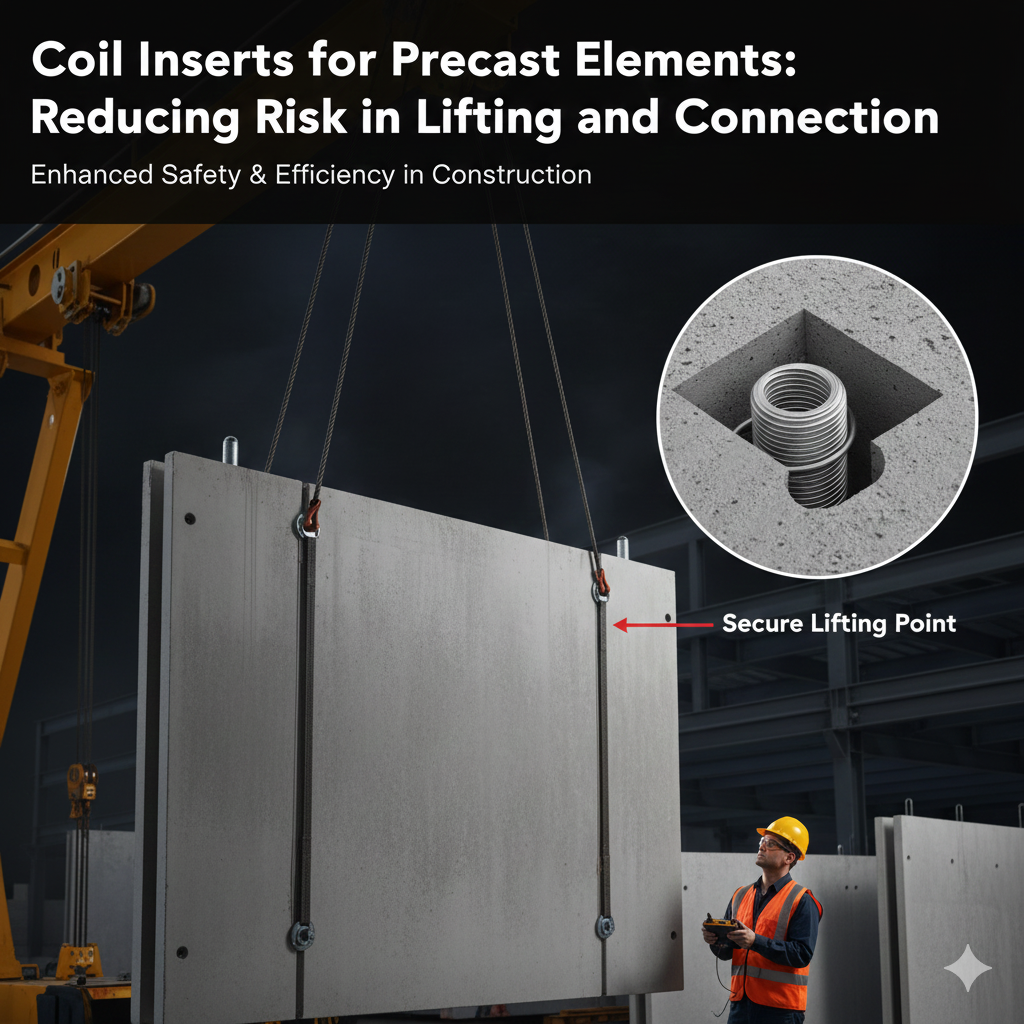

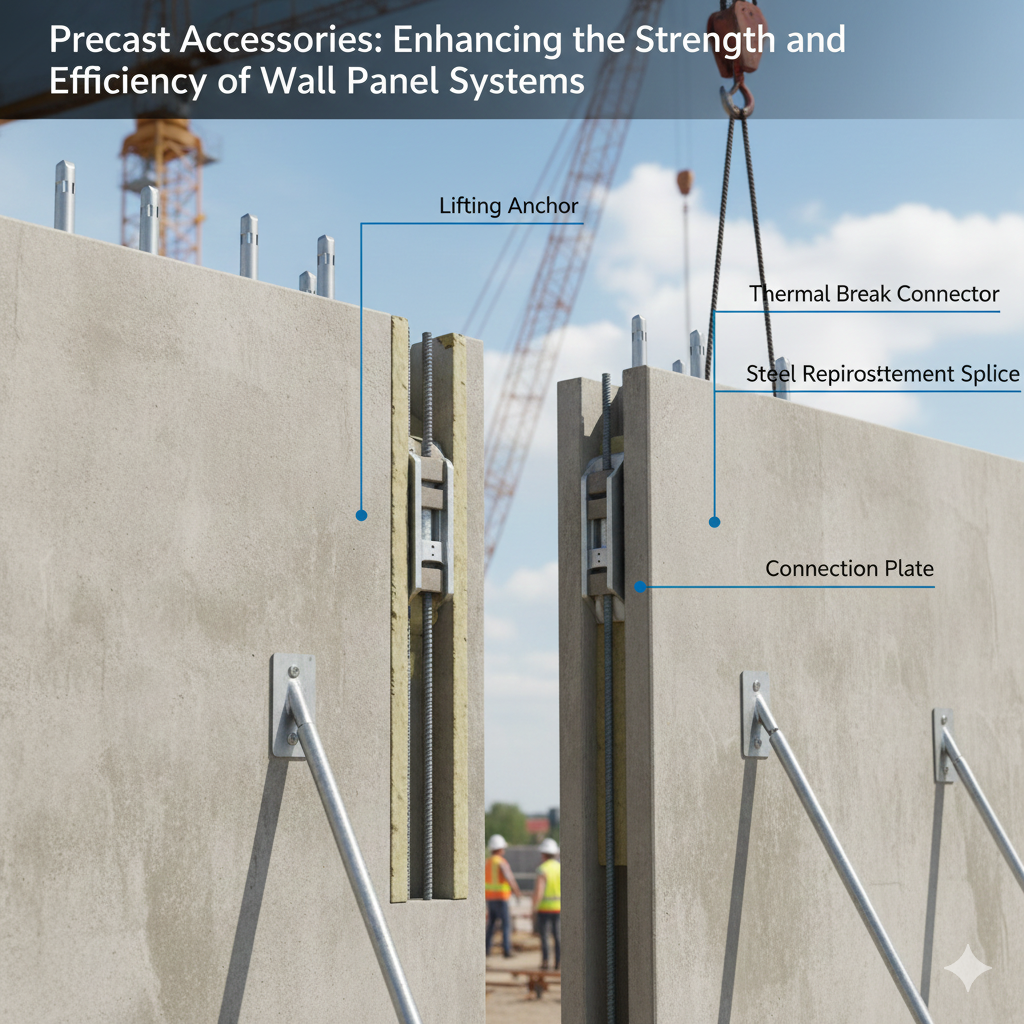

A variety of concrete threaded inserts are available, each tailored to specific load requirements, installation methods, and application environments. One common type is the drop-in anchor, which is set into a pre-drilled hole and expanded using a setting tool, creating a secure threaded socket flush with the concrete surface. Another popular option is the expansion anchor, which expands against the walls of the drilled hole as a bolt is tightened, providing excellent holding power. For heavier loads, cast-in-place inserts are often used; these are positioned before the concrete is poured, becoming an integral part of the structure. Other types include sleeve anchors, which provide a wide bearing surface, and wedge anchors, known for their exceptional tensile strength. Specialized chemical anchors, which utilize epoxy or resin, can also create threaded points and are ideal for challenging conditions or when vibration resistance is paramount.

Versatile Applications of Concrete Threaded Inserts

The utility of concrete threaded inserts spans a wide array of industries and applications. In construction, they are frequently used for securing structural steel elements, support beams, handrails, guardrails, and facade systems. Industrial settings rely on them for anchoring heavy machinery, conveyor systems, pipe supports, and equipment racks, ensuring operational safety and stability. They are also invaluable in infrastructure projects, such as bridge construction and tunnel lining, for attaching signage, lighting fixtures, and utility conduits. Even in residential and commercial buildings, these inserts find uses in attaching shelving, mounting fixtures in garages, or securing awnings. The ability to create a strong, reliable threaded point in concrete makes them a go-to solution for engineers and builders seeking secure fastening.

Why Choose Concrete Threaded Inserts? The Benefits

Employing concrete threaded inserts offers numerous advantages. Their primary benefit is the exceptional holding power they provide, creating a very strong and durable connection capable of withstanding significant tensile and shear loads. This makes them ideal for safety-critical applications. Versatility is another key advantage; with a wide range of types and sizes available, there's an insert suitable for nearly any application or load requirement. Many types of inserts also allow for the removal and reinstallation of the bolted fixture, offering flexibility that is not possible with permanent embedments like rebar. Furthermore, when installed correctly, they can provide a neat, flush finish, contributing to better aesthetics and reducing tripping hazards. Compared to other anchoring methods, many threaded inserts offer relatively straightforward and quick installation processes, saving time and labor costs on site.

Essential Considerations for Installing Threaded Inserts

Proper installation is crucial to ensure the optimal performance and safety of concrete threaded inserts. The process typically begins with drilling a hole of the correct diameter and depth, as specified by the manufacturer. Using the wrong drill bit size can compromise the anchor's holding capacity. The hole must then be thoroughly cleaned of dust and debris using a brush and compressed air; any remaining particles can significantly reduce the anchor's effectiveness. For expansion anchors, it's vital to apply the correct torque during tightening to achieve the necessary expansion without over-stressing the concrete or the anchor itself. For cast-in-place inserts, accurate positioning and securement before concrete placement are paramount. Always refer to the manufacturer's installation instructions, as procedures can vary significantly between different types and brands of inserts. Adhering to these guidelines ensures a secure and lasting anchorage.

Choosing the Right Concrete Threaded Insert for Your Project

Selecting the most suitable concrete threaded insert for a specific application requires careful consideration of several factors. The primary determinant is often the load requirement – both tensile (pull-out) and shear (sideways) forces that the anchor will need to resist. The type and strength of the base concrete material also play a significant role, as does the thickness of the concrete member. Environmental conditions are another important aspect; for instance, in corrosive environments, stainless steel inserts might be necessary. The required embedment depth, edge distances, and spacing between anchors are critical for preventing concrete failure. Finally, consider the nature of the fixture being attached and whether a flush-mount or through-bolt style is more appropriate. Consulting with structural engineers or anchor specialists can be beneficial for complex or critical applications to ensure safety and performance.

The Enduring Value of Threaded Inserts in Concrete

In summary, concrete threaded inserts are fundamental components for creating strong, reliable, and often removable fastening points in concrete structures. Their diverse types cater to a multitude of applications, from light-duty fixtures to heavy-duty structural connections. By understanding the different options available, their specific benefits, and the critical aspects of proper installation and selection, builders and engineers can effectively utilize these fasteners to enhance the integrity, safety, and functionality of their projects. The enduring value of these components lies in their ability to provide secure anchoring solutions that contribute significantly to the overall quality and durability of modern construction.