How to Choose a Reliable Screw Bulk Supplier for Pan Head Applications

When Precision Matters More Than Price

Pan head screws are commonly used in electronics, panels, and light machinery where a flush surface and visual consistency are key. But sourcing them inbulkwithout supplier quality control often leads to:

-

Size deviationsaffecting fitment

-

Inconsistent head shapedisrupting appearance or tool contact

-

Rust-prone finishesdue to poor plating

-

Packaging errorsthat cause line confusion or customs delays

If your application requires precise and clean pan head screw installs, your supplier needs more than just production capacity—they need a structured export process.

Key Qualities of a Dependable Screw Bulk Supplier

A trustworthy screw bulk supplier should be more than a factory—they should be an integrated partner who understands end-use requirements.

Look for these key traits:

-

Full material traceability(e.g. carbon steel, stainless 304, 316)

-

Dimensional checkson thread depth, head diameter, and pitch

-

Plating optionstest reports(zinc, black oxide, etc.)

-

Batch testingwith torque, pull-out, and hardness results

-

Export packagingwith polybags, carton labels, and lot codes

-

Certificationslike ISO 9001, ROHS, or SGS if required for entry

Pro tip:For pan head screws used in consumer electronics or branded goods, ask if your supplier supports laser marking or custom color finishing.

Avoid These Mistakes When Ordering Screws in Bulk

Even experienced buyers fall into common traps:

| Mistake | Risk |

|---|---|

| Choosing based on price alone | Higher sorting/rejection cost later |

| No packaging spec | Customs clearance delays, damage in transit |

| Not confirming material grade | Wrong hardness or rust risk in humid zones |

| No sample confirmation | Surprises during production or installation |

Make sure your quote includes itemized details—not just “pan head screw M4” butmaterial, finish, standard, tolerance, andpacking method.

What Jingle Customers Value in Long-Term Cooperation

At Jingle, our clients across Europe, Southeast Asia, and South America have clear expectations:

-

Consistent specs across batches, even for multi-SKU kits

-

Neutral packaging with buyer label or barcode, ready for direct resale

-

Export documentsincluding CI, PL, CO, and any regional forms(RCEP, FORM E)

-

On-time productionwith photo confirmation before shipment

-

Support for custom pan head screw requests(e.g. wide brim, non-slip slot)

Make Bulk Sourcing Easier, Not Riskier

Whether you need a standardpan head screwor a mix of fasteners inbulk, working with the right supplier will save you time and reduce downstream loss.

-

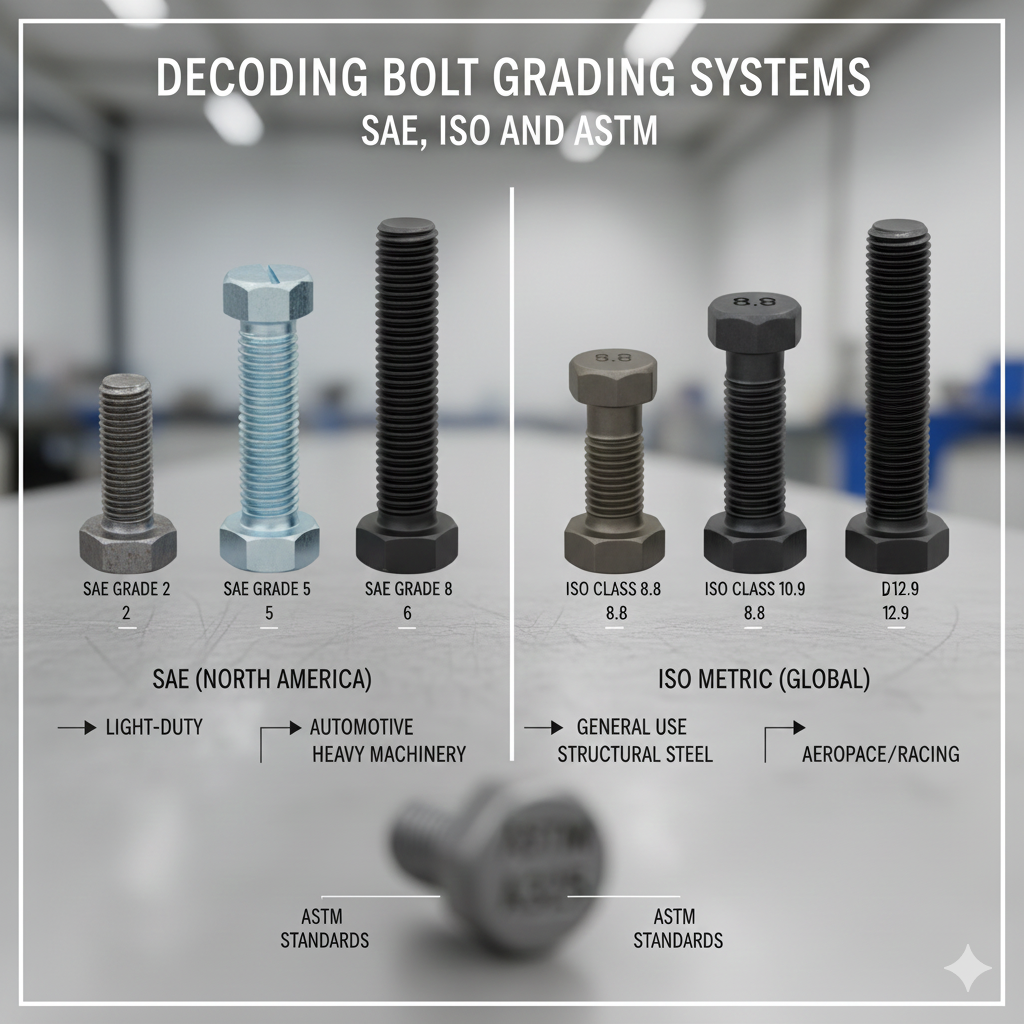

✔ Confirm standards: DIN, ANSI, ISO

-

✔ Ask for finish & test reports

-

✔ Align packaging with your warehouse workflow

-

✔ Plan for forecasted reorders—ensure long-term mold stability

Start with a Proven Process

Sourcing doesn’t have to be trial and error. When working with bulk fasteners, especially pan head screws used in OEM or industrial assembly, you deserve:

-

Clarity

-

Consistency

-

Compliance

You canvisit our homepagefor more about our screw manufacturing process, orcontact us directlyto discuss your bulk needs, get packaging photos, or request a pre-shipment spec sheet.

A better screw supply chain starts from better supplier thinking.