Bulk Screw Sourcing in 2025: How to Avoid Quality Traps and Delivery Delays

The Real Risks in Global Screw Supply

Sourcing screws in bulk might seem straightforward—until delays, misfits, and rejections start hitting your projects. Whether you're supplying a hardware chain, assembling kits, or running a distribution business, common issues include:

-

Inconsistent thread standardscausing mismatches with nuts or components

-

Undetected surface cracksleading to part failure during assembly

-

Rusting during transitdue to poor plating or improper packaging

-

Missing documentationdelaying customs clearance at ports

These are not rare exceptions. In a recent report by Global Sourcing Insights (2024),34% of importerscited "hidden quality defects" and21%flagged "non-compliant packing or paperwork" as causes of loss in fastener imports.

What Sets a Reliable Screw Wholesale Supplier Apart?

Screw supply isn’t just about boxes and bolts—it’s a system. The best suppliers address these core needs:

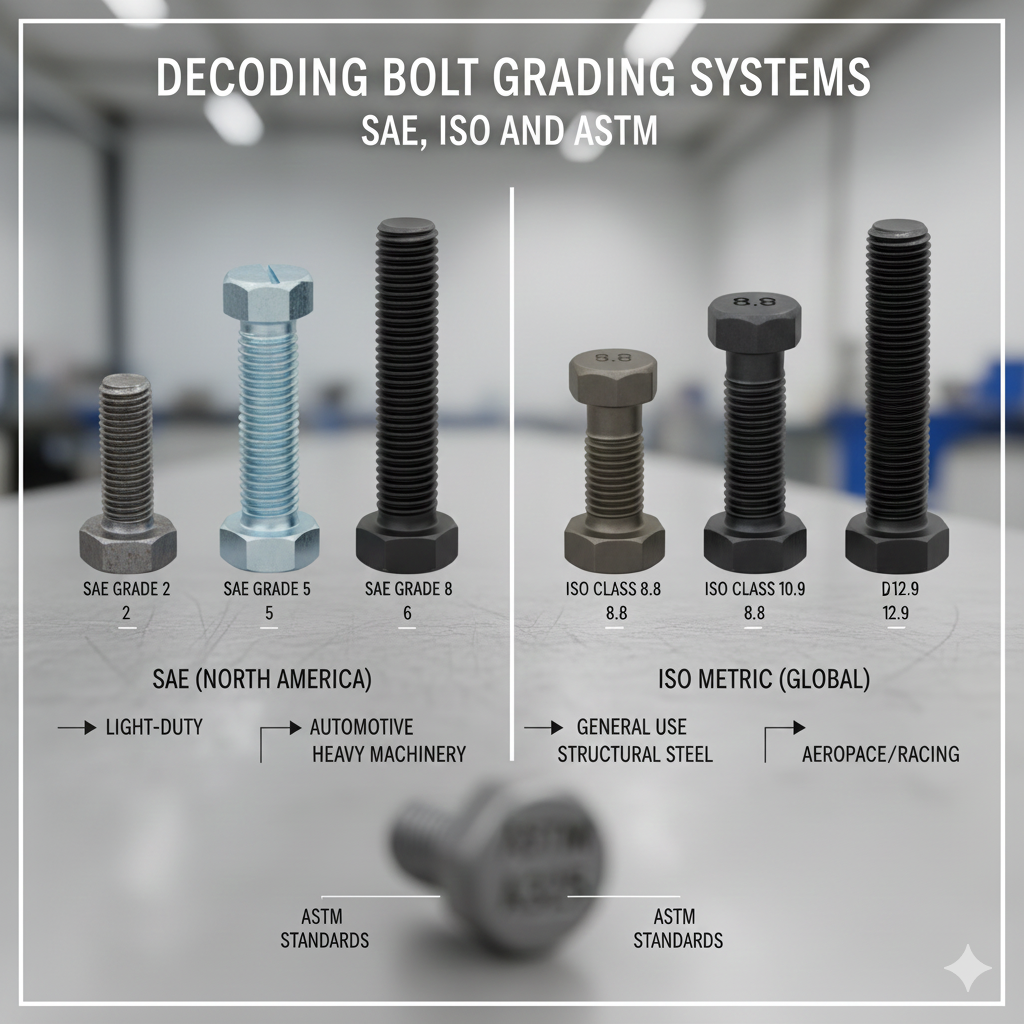

1.Thread Precision and Material Control

Screws that fail to meet DIN/ISO/ANSI specs can ruin entire assemblies. A reliable screw supply supplier:

-

Conducts thread ring gauge inspections

-

Maintains raw material traceability (with certificates)

-

Offers mechanical property reports (hardness, tensile, shear)

Don’t just ask for "good quality"—ask for their test method and frequency.

2.Export-Grade Packaging and Compliance

A well-prepared screw wholesale set should come with:

-

Neutral cartons or brand-ready packs

-

Desiccant-lined bags to prevent corrosion during ocean shipping

-

English-labeled specifications and traceable batch numbers

-

Export paperwork: CO, CI, PL—plus FORM E or RCEP if needed

This reduces clearance delays and ensures your goods are resale-ready the moment they land.

3.Flexible MOQ and Customization Support

For distributors and OEM clients, it’s often not "how cheap" but "how usable." Ideal partners support:

-

Trial orders with mixed-size SKUs

-

Private label or barcoded packaging

-

Custom head types, finishes (zinc, oxide, anodizing), and fit tolerances

-

Screw sets that match toolkits, pre-assembled kits, or repair packs

Case-in-Context: What Buyers Actually Need

A European client importing screw kits for tool manufacturers required 4 types of M4 screws per box with ±0.02mm length tolerance, passivated finish, English box labels, and palletized delivery.

Their previous supplier delivered on time—but half the screws didn’t fit spec. After customs issues due to mislabeling, they switched to a structured supplier who handled sample confirmation, plating certificates, and provided packing photos pre-shipment.

This shift saved not just cost, but reputation. It’s not uncommon. As manufacturing globalizes, so mustsupply professionalism.

Practical Tips When Comparing Screw Wholesale Suppliers

-

Request dimensional inspection data—not just photos

-

Check if they can do export packaging before trial order

-

Ask for previous shipping records or customer regions

-

Test their response time on RFQs and sample issues

-

If offering sets, check if they support size mixing or kit assembly

These practical questions often reveal the difference between a workshop and a supply chain partner.

Your Checklist Before Committing

Choosing ascrew wholesale suppliertoday means managing more than cost—it’s about risk reduction and long-term reliability. Here’s what your supplier should provide:

Verified thread and material quality

Export-compliant packaging and documents

Flexible production and MOQ support

Set configuration for easy resale or assembly

Open communication and follow-through service

Whether you're just starting with a sample or managing a yearly container flow, setting these expectations early is key to a successful sourcing partnership.

Ready to Upgrade Your Screw Supply Strategy?

For importers, wholesalers, or industrial buyers seeking better control over fastener sourcing, it’s time to work with suppliers that match modern B2B expectations. Learn more about how structured, export-focused screw supply works on ourhomepageorcontact our team herefor a quote or consultation.

Let your sourcing save time—not create problems.