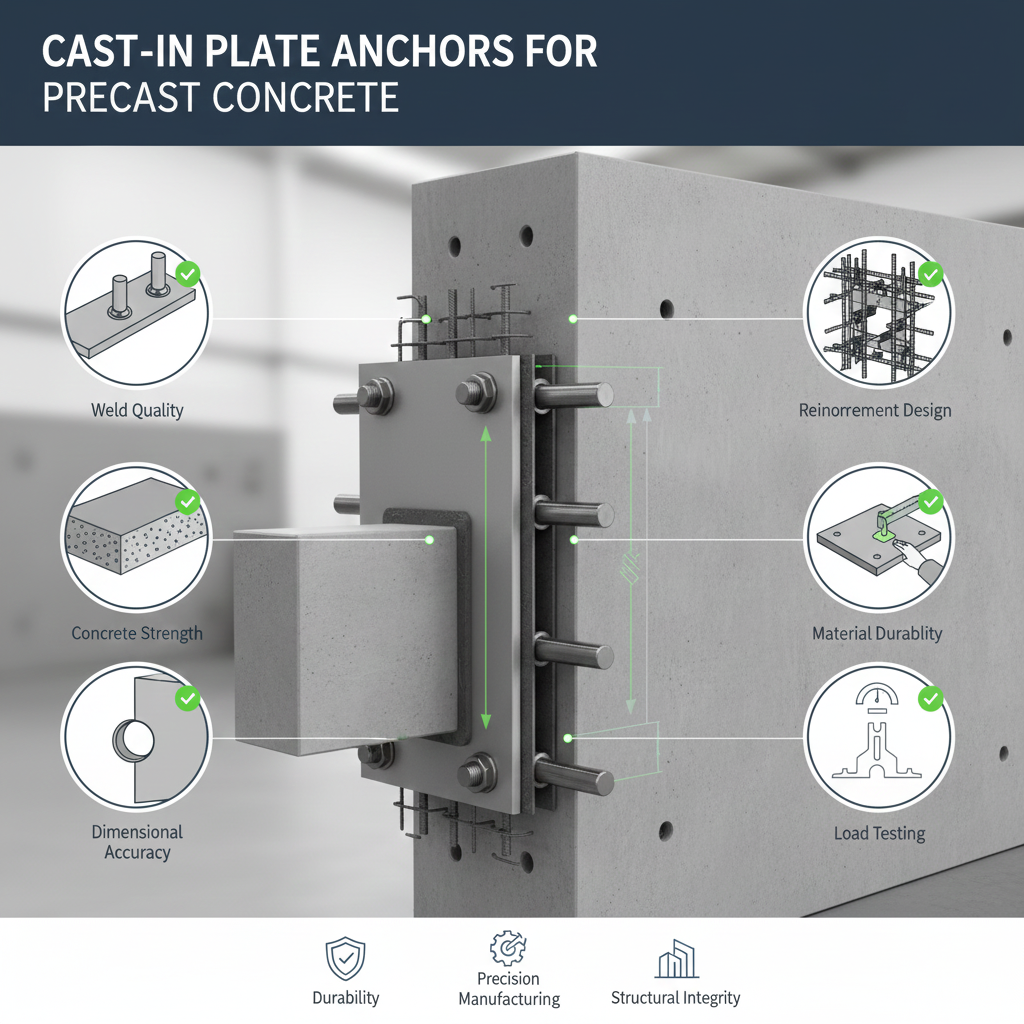

Cast-In Plate Anchors in Precast Concrete: Load Transfer, Tolerance, and Supply Control

In precast concrete construction, connection failure rarely originates from the concrete itself.

It usually begins at the interface—where steel must transfer load reliably into hardened concrete under imperfect site conditions.

Cast-in plate anchors sit precisely at that interface. Their performance is not defined by plate thickness alone, but by load path continuity, embedment accuracy, and repeatability across panels. When those variables drift, the consequences appear during erection, not inspection.

This is why choosing a cast in plate anchor supplier is ultimately a structural decision, not a sourcing formality.

Load Transfer Depends on More Than Plate Strength

A cast-in plate anchor does not behave as an isolated steel component. It acts as a transition zone between steel and concrete, distributing load through studs, ribs, or welded anchors into the surrounding matrix.

If load transfer is uneven, stress concentrates at weld toes or stud roots, increasing the likelihood of cracking or long-term fatigue.

| Structural factor | Effect on load behavior |

|---|---|

| Stud diameter and spacing | Stress distribution |

| Weld penetration | Load continuity |

| Plate flatness | Contact consistency |

| Embedment depth | Pull-out resistance |

A capable cast in plate anchor supplier designs these variables as a system rather than optimizing any single parameter in isolation.

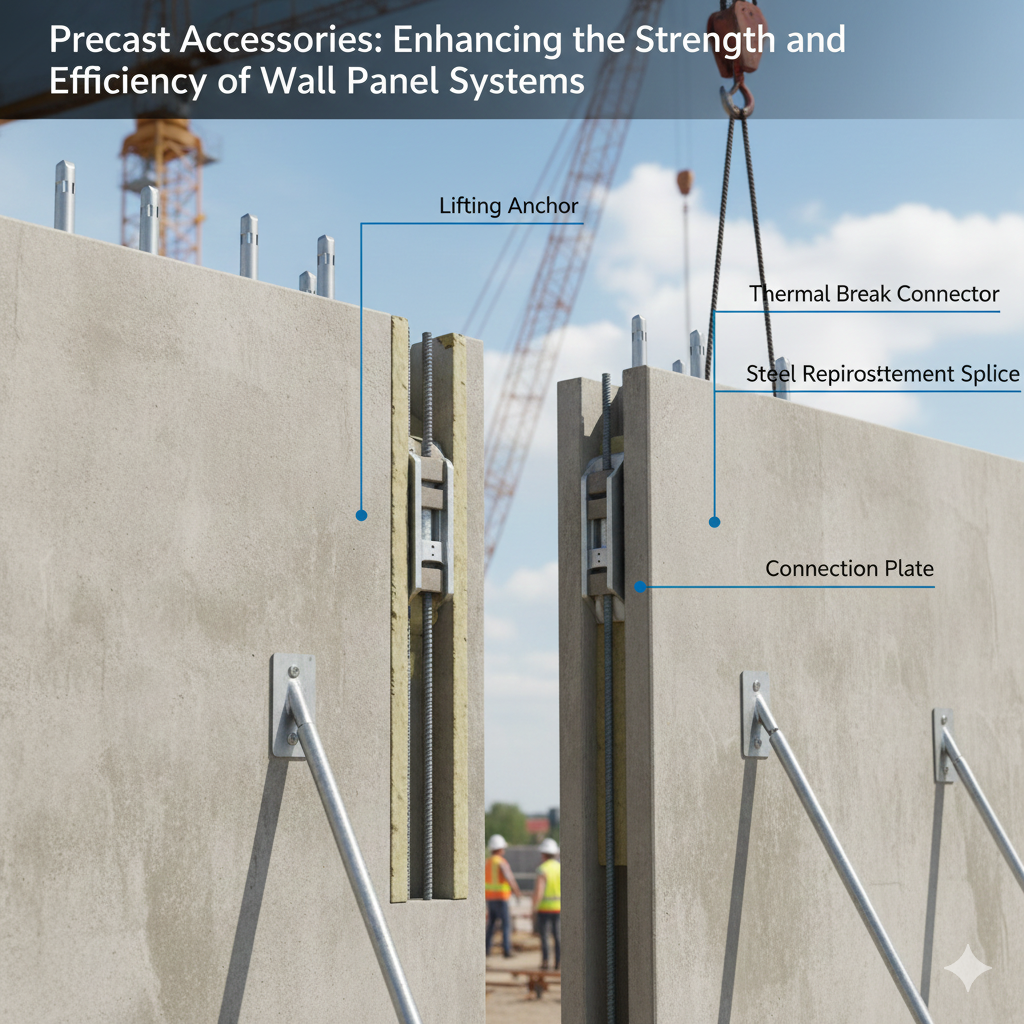

Embedment Accuracy Is the First Field Failure Trigger

In precast elements, anchor plates must align with reinforcement, formwork, and connection hardware simultaneously. Even minor embedment deviation can cascade into site-level problems.

Common issues include:

-

misaligned bolt patterns during erection

-

forced fit connections introducing unintended stress

-

on-site welding adjustments that alter load paths

| Embedment deviation | Typical site consequence |

|---|---|

| Plate tilt | Uneven load transfer |

| Offset positioning | Connection misalignment |

| Height variation | Shim stacking or rework |

Most of these failures originate upstream, when supplier processes do not control embedment geometry consistently.

Welding Quality Directly Affects Structural Reliability

In cast-in plate anchors, welds are not cosmetic. They are load-bearing elements.

Incomplete fusion, inconsistent weld size, or heat distortion can all compromise performance, especially in cyclic or dynamic load conditions.

| Welding aspect | Structural implication |

|---|---|

| Weld penetration | Shear capacity |

| Heat input control | Plate distortion |

| Weld placement repeatability | Load symmetry |

This is a key differentiator between general fabrication and a true cast in plate anchor supplier focused on structural outcomes.

Tolerance Strategy Determines Installation Efficiency

Tolerance is not about making parts “tighter.”

It is about ensuring predictable fit under real site conditions.

Overly tight tolerances increase rejection risk during casting. Overly loose tolerances shift alignment burden to installers.

| Tolerance approach | Project impact |

|---|---|

| Nominal-only control | Assembly uncertainty |

| Over-tight control | Casting rejection |

| Functional tolerance zoning | Predictable erection |

Experienced suppliers define tolerances based on how anchors are actually installed, not how drawings look in isolation.

Customization Amplifies Risk Without Process Discipline

Cast-in plate anchors are frequently customized for:

-

panel thickness variation

-

special load cases

-

unique connection geometry

Each customization introduces new interaction between plate, studs, and concrete. Without revalidation of weld layout, stud spacing, and embedment depth, customization shifts risk directly into the structure.

A mature cast in plate anchor supplier evaluates customization by structural impact, not just manufacturability.

Cost Escalation Often Comes From Installation, Not Fabrication

The apparent cost of a cast-in plate anchor is small compared to the cost of correcting misalignment or welding issues on site.

Typical downstream cost drivers include:

-

erection delays

-

re-welding under constrained access

-

non-conforming inspections

-

structural redesign adjustments

Across large precast projects, these issues can increase total connection-related cost by 15–25%, even when anchor pricing appears competitive.

Where Cast-In Plate Anchors Are Structurally Appropriate

Cast-in plate anchors are most effective in:

| Application | Structural requirement |

|---|---|

| Precast wall panels | Load transfer and alignment |

| Structural frames | Shear and moment resistance |

| Parking structures | Repetitive connection accuracy |

| Industrial buildings | Heavy connection loads |

| Infrastructure elements | Long-term durability |

In these applications, system-level control matters more than individual component strength.

Common Buyer Questions

Q1: Why do anchor plates pass inspection but fail during erection?

Because inspection often checks dimensions, while erection exposes embedment alignment and load-path continuity issues.

Q2: Can standard welded studs be used for all plate anchors?

Not reliably. Stud size, spacing, and weld detail must match the specific load case and concrete geometry.

Q3: Does thicker plate steel improve anchor performance?

Only to a point. Beyond that, weld quality and embedment control become the dominant factors.

Conclusion

Cast-in plate anchors succeed when load transfer, embedment accuracy, welding quality, and tolerance strategy are treated as a single system. A reliable cast in plate anchor supplier controls these interactions upstream, preventing costly corrections during erection.

For an overview of precast connection hardware and structural anchor solutions used in real projects, visit

👉 Jingle Home Page

If you are working with drawings, connection details, or active precast projects and need to assess anchor configuration, customization feasibility, or installation risk, early technical discussion helps prevent downstream structural and scheduling issues:

👉 Contact Jingle