Lifting Inserts for Concrete Slabs: Reducing Lifting Risk and Site Rework

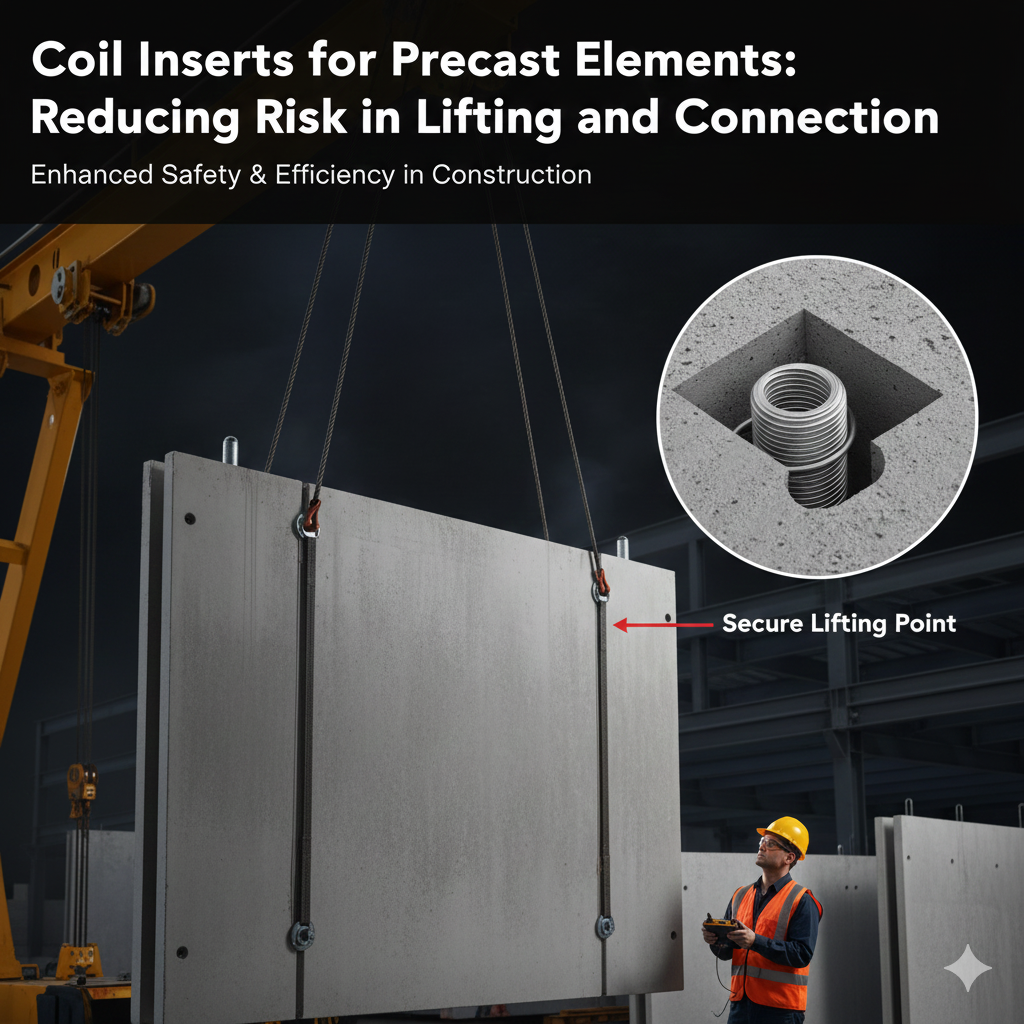

In precast construction, lifting problems rarely result from miscalculating slab weight alone. More often, issues appear during the first lift: slabs rotate unexpectedly, lifting points carry uneven loads, or crews pause operations to adjust rigging. These situations usually trace back to how the lifting insert for concrete slab was selected, positioned, and supplied. When embedment depth, insert orientation, or load assumptions are not aligned with real lifting conditions, inspection records offer limited protection once the slab leaves the casting bed.

How Load Actually Acts on a Concrete Slab During Lifting

A concrete slab does not behave as a perfectly rigid body when lifted. Load distribution changes as the slab rotates, accelerates, and stabilizes in the air. Inserts closest to the crane hook or subjected to tighter sling angles often experience higher forces than the calculated average. If a lifting insert for concrete slab is chosen based only on static slab weight, local overstressing may occur even when nominal capacity appears sufficient.

Key load-related factors that influence insert performance

-

Sling angle and number of lifting points

-

Slab geometry and thickness variation

-

Presence of openings or asymmetric reinforcement

-

Dynamic effects during initial lift-off

Ignoring these variables shifts lifting risk from the design stage to the construction site.

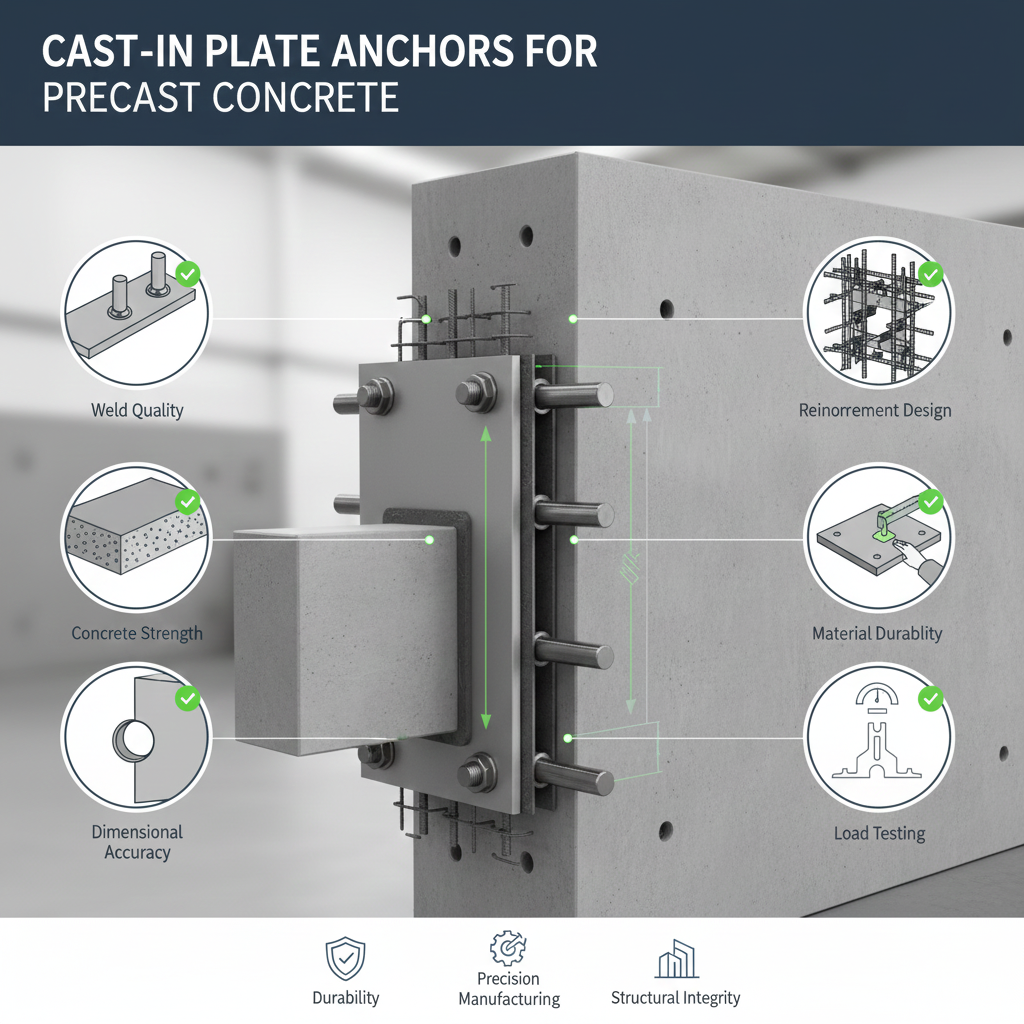

Material and Manufacturing Factors That Affect Insert Reliability

From a manufacturing perspective, lifting inserts are not interchangeable commodities. Material grade consistency, forming method, and dimensional repeatability all influence how load is transferred into the surrounding concrete. Carbon steel and alloy steel are commonly used, with surface treatments selected based on handling and exposure conditions rather than appearance.

For a lifting insert for concrete slab, performance variation often originates from:

-

inconsistent steel properties across production batches

-

thread form variation affecting engagement with lifting clutches

-

surface condition influencing seating and load transfer

-

dimensional tolerance drift in embedment-critical features

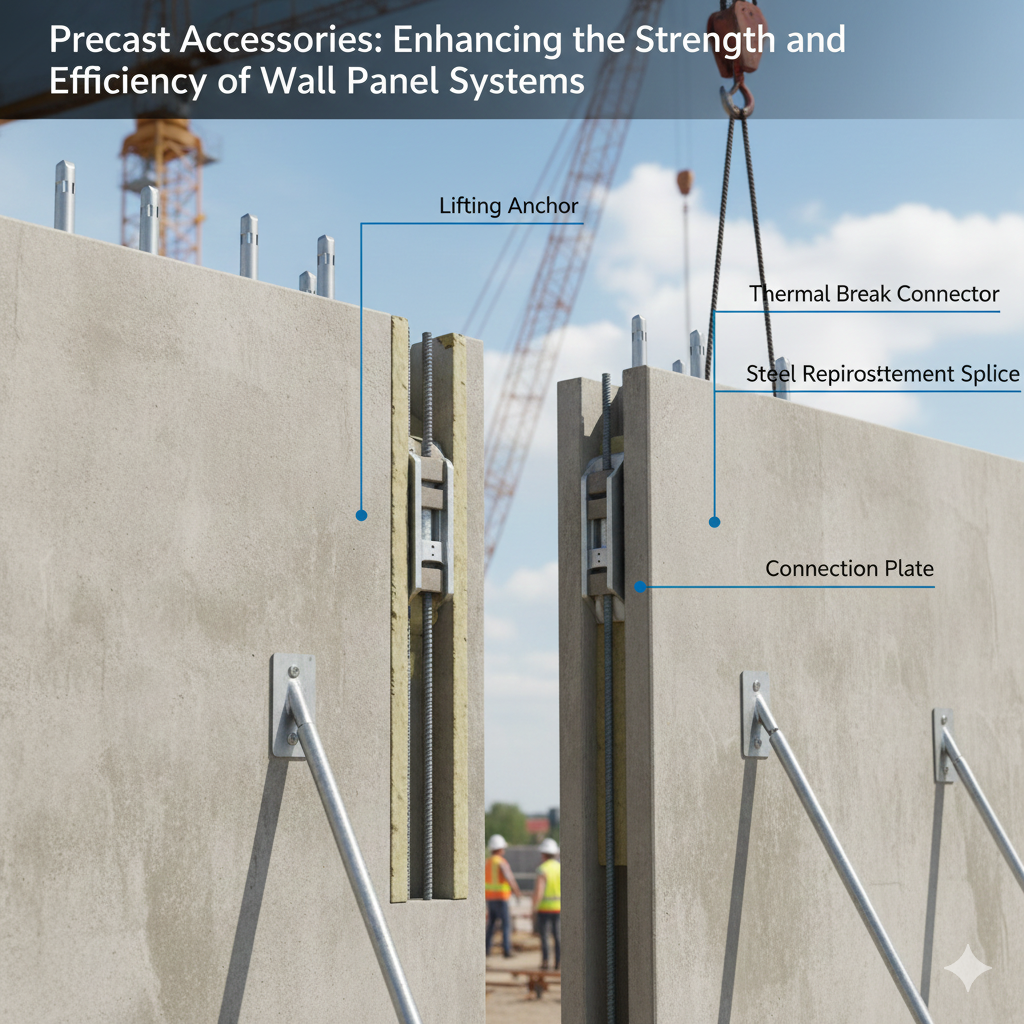

Within Jingle’s scope, supplying precast accessories alongside CNC-machined custom components allows tighter control over insert geometry and project-specific adaptation. In practice, insert pricing reflects not only material cost, but also the level of process control applied to reduce lifting variability on site.

Selection Logic That Prevents Common Lifting Failures

Most lifting-related incidents fall into three categories: incorrect load assumptions, embedment deviation, and lifting before sufficient concrete strength is achieved. Effective selection begins with the lifting plan rather than the insert catalogue.

Practical selection steps used on stable precast projects

-

Define lifting configuration, including sling angle and rotation requirements

-

Confirm concrete strength at the planned lifting date

-

Match insert type and embedment length to slab behavior, not slab weight alone

-

Control embedment positioning during casting, not after curing

-

Avoid mixing inserts from different production lots within the same lift

A lifting insert for concrete slab should be evaluated as part of a lifting system. Selecting a higher-rated insert without correcting embedment or load-path issues often increases cost without reducing risk.

Where Lifting Risk and Cost Escalate in Practice

The table below summarizes how common deviations affect lifting behavior and project outcomes. The percentages reflect typical industry experience ranges used for risk assessment and planning purposes.

| Lifting deviation | Observed site effect | Typical impact |

|---|---|---|

| Embedment depth reduced by ~10% | Surface cracking near insert | 10–15% increase in handling time |

| Insert angular deviation >5° | Uneven load distribution | 20–30% increase in safety risk |

| Concrete strength below target at lift | Breakout cone risk | 15–25% probability of lift delay |

| Mixed insert batches | Inconsistent engagement | 5–10% increase in rework time |

| Tight sling angle | Higher dynamic load | 10–20% peak load increase |

Most lifting-related cost increases are indirect, appearing as additional crane time, revised lifting plans, and safety inspections rather than higher insert prices.

Common Buyer Questions

Q: How can I avoid selecting an insert that causes lifting adjustments on site?

A: Select the lifting insert for concrete slab based on actual lifting configuration, embedment accuracy, and concrete strength at lift time rather than slab weight alone.

Q: Can higher-rated inserts compensate for early lifting when concrete strength is low?

A: No, higher hardware capacity cannot offset insufficient concrete strength or reduce breakout and cracking risk during early lifting.

Q: Why does batch consistency matter if part numbers are identical?

A: Small variations between production batches affect engagement and load transfer, leading to uneven lifting behavior and additional site checks.

Conclusion and Next Steps

Reliable slab lifting depends on predictable load transfer, accurate embedment, sufficient concrete strength, and consistent supply quality. When these factors align, a lifting insert for concrete slab performs as expected, reducing site delays and safety exposure.

To review precast accessories capability and related lifting hardware supply, visit:

👉 https://jinglefix.com/

If you have slab drawings, lifting layouts, or a planned lifting schedule and want to validate insert selection before procurement, technical discussion at the planning stage can help avoid on-site rework:

👉 https://jinglefix.com/en/contact-us