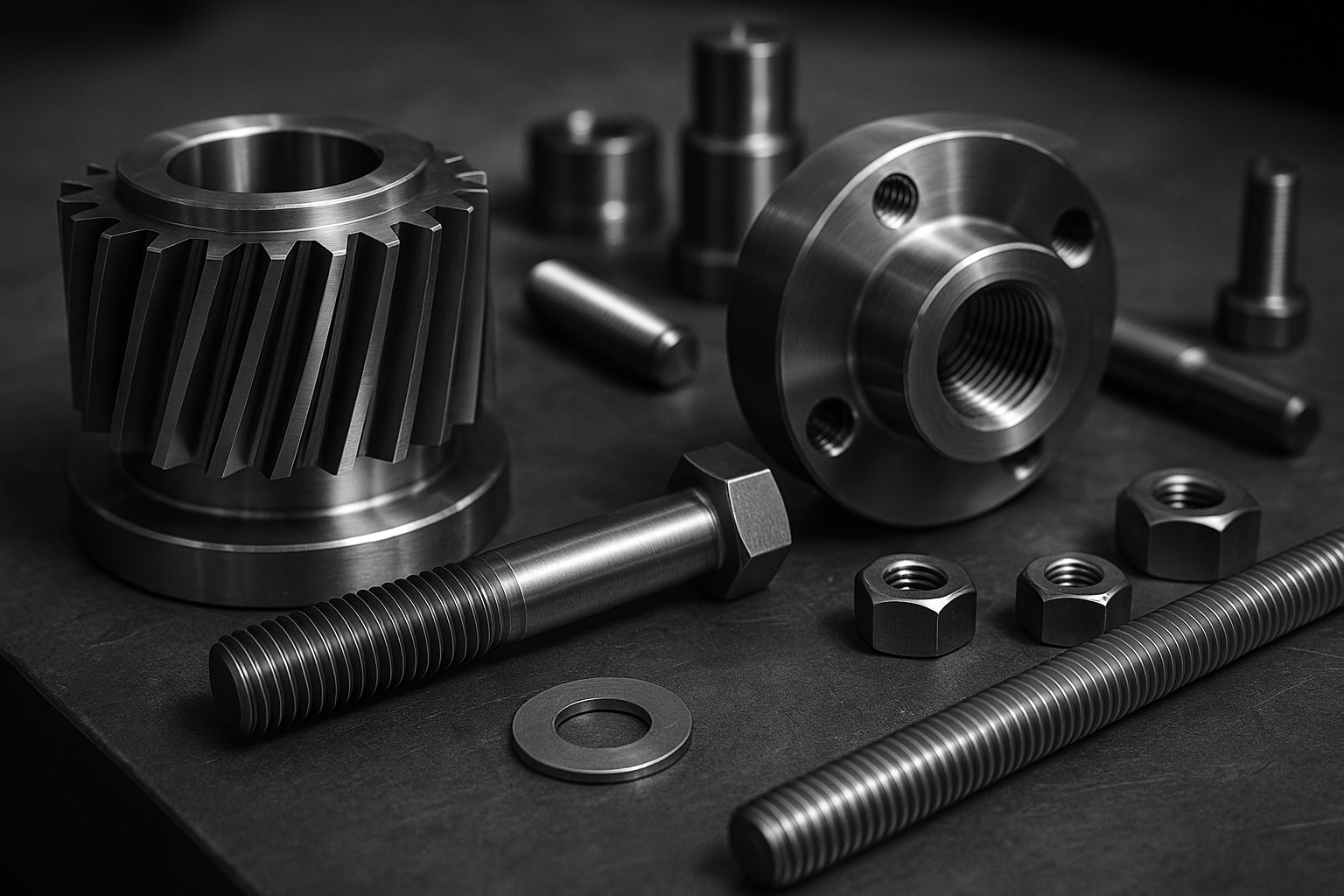

Custom CNC Machining Parts: Precision and Performance

The Demand for Accuracy in Modern Manufacturing

In today’s industrial landscape, precision is more than a quality metric—it’s a competitive advantage. From aerospace engines to medical devices and automation systems, even a fraction of a millimeter can decide whether a product performs flawlessly or fails prematurely.

Custom CNC machining parts address this challenge by delivering components specifically engineered for each application. Unlike generic, mass-produced pieces, CNC-customized parts maintain consistent tolerances, surface finishes, and mechanical integrity across production runs.

According to Machinery Market Review 2024, over 60% of global manufacturers now rely on customized CNC parts to enhance quality control and reduce post-processing costs.

Principles Behind CNC Precision

CNC (Computer Numerical Control) machining operates on a simple but powerful principle—digital accuracy translated into mechanical execution. Every movement, cut, and feed rate is guided by pre-programmed instructions that ensure flawless replication from prototype to mass production.

The process involves:

-

CAD-to-CAM integration for perfect alignment between digital design and machining output.

-

Multi-axis control (3, 4, or 5-axis) to achieve complex geometries and surface continuity.

-

High-speed milling and turning for smooth edges and micro-level precision.

-

Material optimization ensuring uniform stress distribution and enhanced part durability.

This level of control eliminates human error, reduces waste, and guarantees repeatable precision for even the most demanding applications.

Comparing Custom CNC Parts vs. Standard Components

| Criteria | Standard Components | Custom CNC Machining Parts |

|---|---|---|

| Design Flexibility | Limited to catalog shapes | Fully tailored geometry and dimensions |

| Tolerances | ±0.2–0.5 mm typical | ±0.005–0.02 mm achievable |

| Material Range | Standard steel or aluminum | Stainless, titanium, brass, composites, plastics |

| Surface Finish | Basic | Mirror-polished, anodized, or coated |

| Production Consistency | Moderate | Digitally controlled, zero deviation |

With CNC customization, manufacturers achieve both performance stability and material optimization, aligning each component precisely with operational requirements.

Applications Across Industrial Sectors

-

Aerospace & Aviation – turbine housing, landing gear, and sensor housings built to exact load tolerances.

-

Automotive & EVs – high-precision drivetrain components and cooling system connectors.

-

Medical Equipment – surgical tools and prosthetic parts requiring biocompatible materials and ultra-smooth finishes.

-

Industrial Automation – robotic arms and jigs demanding tight tolerance for alignment and motion control.

-

Energy Systems – heat exchanger fittings and hydraulic connectors resistant to pressure fatigue.

These applications highlight how CNC machining adapts across industries where precision, reliability, and long-term performance are non-negotiable.

Practical Recommendations for OEM Buyers

-

Collaborate early with CNC engineers to ensure geometry optimization before tooling begins.

-

Select materials based on environment—consider corrosion, heat, and fatigue resistance.

-

Request inspection reports, including CMM and surface roughness validation, for every production lot.

-

Balance tolerance with cost, as ultra-tight tolerances may add machining time without proportional performance gain.

-

Integrate quality checkpoints to maintain dimensional integrity in high-volume runs.

Strategic collaboration with OEM CNC suppliers ensures both technical precision and cost efficiency.

How CNC Machining Enhances Performance and Efficiency

-

Reduced Assembly Error: Perfect alignment eliminates post-adjustments.

-

Improved Product Lifespan: High surface integrity minimizes wear.

-

Streamlined Production: Faster setup and automated control shorten lead times.

-

Sustainability: Reduced material waste and energy-efficient operations support eco-friendly manufacturing goals.

The result is a production model that blends accuracy, efficiency, and environmental responsibility—qualities essential for next-generation manufacturing.

Jingle’s Advantage in CNC Customization

At Jingle, precision is built into every process. Our custom CNC machining parts are produced using advanced 5-axis machining centers, CAD/CAM integration, and ISO 9001-certified quality management systems.

-

Expertise in multi-material machining (stainless steel, brass, titanium, aluminum).

-

Comprehensive surface finishing—anodizing, polishing, sandblasting, or plating.

-

Batch consistency ensured by full CMM inspection and digital traceability.

-

Support for OEM/ODM collaboration from prototype to mass production.

From concept to completion, Jingle delivers components that combine precision, durability, and performance—empowering industries to achieve smarter, faster, and more reliable production.

Learn more about our CNC capabilities on the homepage or reach out via the contact page.