The Structural Challenge Behind Every Connection

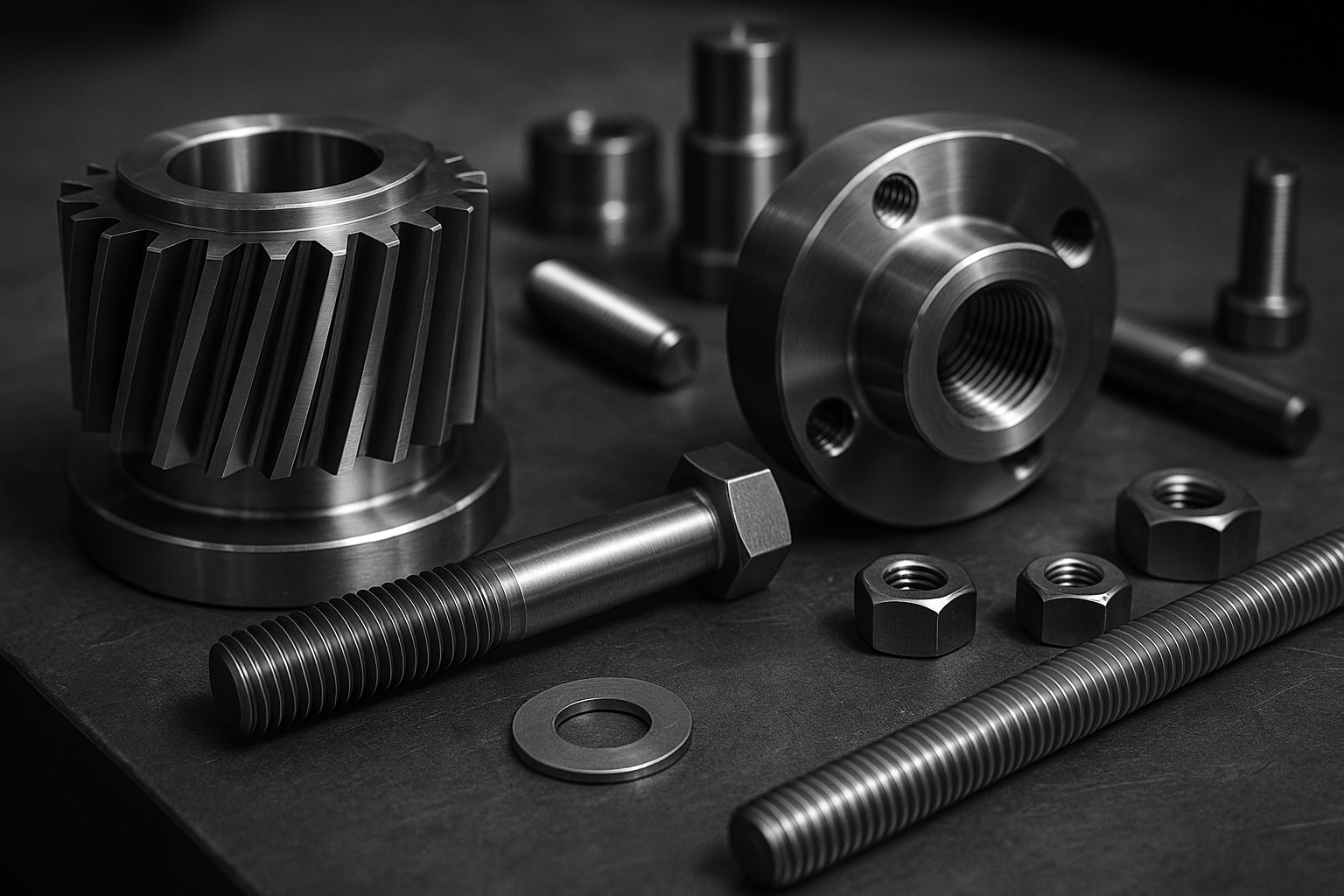

In heavy machinery, energy infrastructure, and high-rise construction, every joint matters. A single weak fastener can compromise an entire structure’s integrity. Standard bolts often fail when exposed to extreme loads, vibration, or corrosion.

This is why custom high-strength fasteners have become indispensable. Engineered for precision and endurance, they combine metallurgical control with advanced machining to maintain stability under mechanical stress, ensuring reliability in mission-critical applications.

Principle: Engineering Strength from the Inside Out

High-strength fasteners are not simply “harder bolts.” Their performance comes from metallurgical balance, controlled heat treatment, and precise geometry.

Key engineering mechanisms include:

-

Alloy composition optimization: Using Cr-Mo or Ni-Cr steel blends to achieve tensile strength above 1,000 MPa.

-

Heat treatment cycles: Quenching and tempering improve hardness while preserving ductility.

-

CNC rolling and threading: Produces fiber-flow alignment for increased fatigue resistance.

-

Surface coating systems: Dacromet, zinc-nickel, or hot-dip galvanization for corrosion control.

Each process ensures the fastener’s microstructure can resist stretching, shearing, and thread deformation under prolonged load cycles.

Standard vs. Custom High-Strength Fasteners

| Property | Standard Fasteners | Custom High-Strength Fasteners |

|---|---|---|

| Tensile Strength | 400–600 MPa | 1,000–1,400 MPa |

| Fatigue Resistance | Moderate | Enhanced through fiber-flow threading |

| Surface Protection | Basic zinc plating | Zinc-nickel / Dacromet / duplex coating |

| Thread Tolerance | ±0.5 mm | ±0.05 mm CNC control |

| Heat Treatment | Generic | Controlled multi-stage process |

Custom fasteners turn mechanical weakness into structural confidence, providing a level of consistency unattainable with mass-produced components.

Core Advantages: The Science of Structural Reliability

1. Enhanced Tensile Strength

Precisely controlled alloy compositions and heat treatment deliver performance stability even under extreme mechanical loads.

2. Fatigue and Impact Resistance

CNC-rolled threads improve grain continuity, reducing stress concentration points and extending fatigue life.

3. Corrosion Protection

Advanced coatings withstand 1,000+ hours of salt-spray testing—critical for offshore, energy, and infrastructure use.

4. Design Flexibility

Head geometry, length, and thread pitch can be tailored to project-specific torque or shear requirements.

5. Certified Quality

All Jingle fasteners meet or exceed ISO 898-1, ASTM A490, and DIN EN 14399 standards, ensuring international reliability.

Application Scenarios: Where Strength Meets Necessity

-

Wind Energy Systems – Bolts maintain stability under cyclic wind loads and high-torque tightening conditions.

-

Bridge and Tunnel Construction – High-strength anchors prevent joint slippage in vibration-heavy environments.

-

Heavy Machinery – Engine and chassis bolts sustain continuous pressure and mechanical fatigue.

-

Petrochemical Plants – Corrosion-resistant coatings ensure reliability in high-temperature, acidic environments.

-

Rail and Transport Systems – Customized tensile fasteners withstand dynamic stresses and temperature fluctuations.

Each of these applications proves one thing—precision-engineered fasteners are the backbone of safety and performance.

Professional Selection Guidance: Choosing Fasteners by Use Case

Choosing the right fastener requires balancing mechanical strength, environment, and assembly conditions. Below is a practical selection framework for different operational demands:

| Environment / Application | Recommended Material | Coating & Finish | Technical Notes |

|---|---|---|---|

| High Vibration (Machinery, Engines) | Cr-Mo alloy steel | Zinc-nickel coating | Prioritize fatigue resistance and torque retention. |

| Outdoor / Marine Construction | Stainless steel (A4 / 316) | Hot-dip galvanization or Dacromet | Focus on corrosion protection and thread sealing. |

| High-Temperature Systems | Alloy steel with Mo or Ni additive | Heat-resistant black oxide | Prevents creep and strength loss under heat. |

| Structural Steel Frameworks | Carbon steel (Grade 10.9+) | Duplex zinc coating | For high shear applications and safety-critical joints. |

| Precision Assemblies (Aerospace / Automation) | Titanium or high-nickel alloy | Anodized / chemical film | Maximize strength-to-weight ratio with minimal galling. |

Practical insight:

-

Avoid over-hardening; excessive hardness reduces fatigue resistance.

-

Match fastener coating to the same potential of the joining material to prevent galvanic corrosion.

-

For high-load applications, torque testing under actual assembly conditions should always be conducted.

Strategic Perspective: Redefining the Standards of Strength

In industries where failure is not an option, custom high-strength fasteners represent more than just mechanical parts—they are engineered safeguards. Through metallurgical precision, digital manufacturing, and international certification, they ensure that strength is predictable, repeatable, and measurable.

At Jingle, we specialize in OEM-grade fastener engineering, combining high-tensile alloys, precision CNC threading, and advanced surface treatments to create solutions tailored to your project’s mechanical demands.

To explore our range of custom high-strength fasteners or discuss specialized solutions, visit our homepage or contact our engineering team through the contact page.