Precision at Scale: How OEM Precast Accessories Reshape Modern Construction

Structural Consistency and the Need for OEM Integration

Across today’s construction landscape, achieving consistent quality across hundreds of components is a formidable challenge. Traditional production often suffers from inconsistent tolerances, incompatible fittings, and variable coatings—all of which slow down installation and weaken structural reliability.

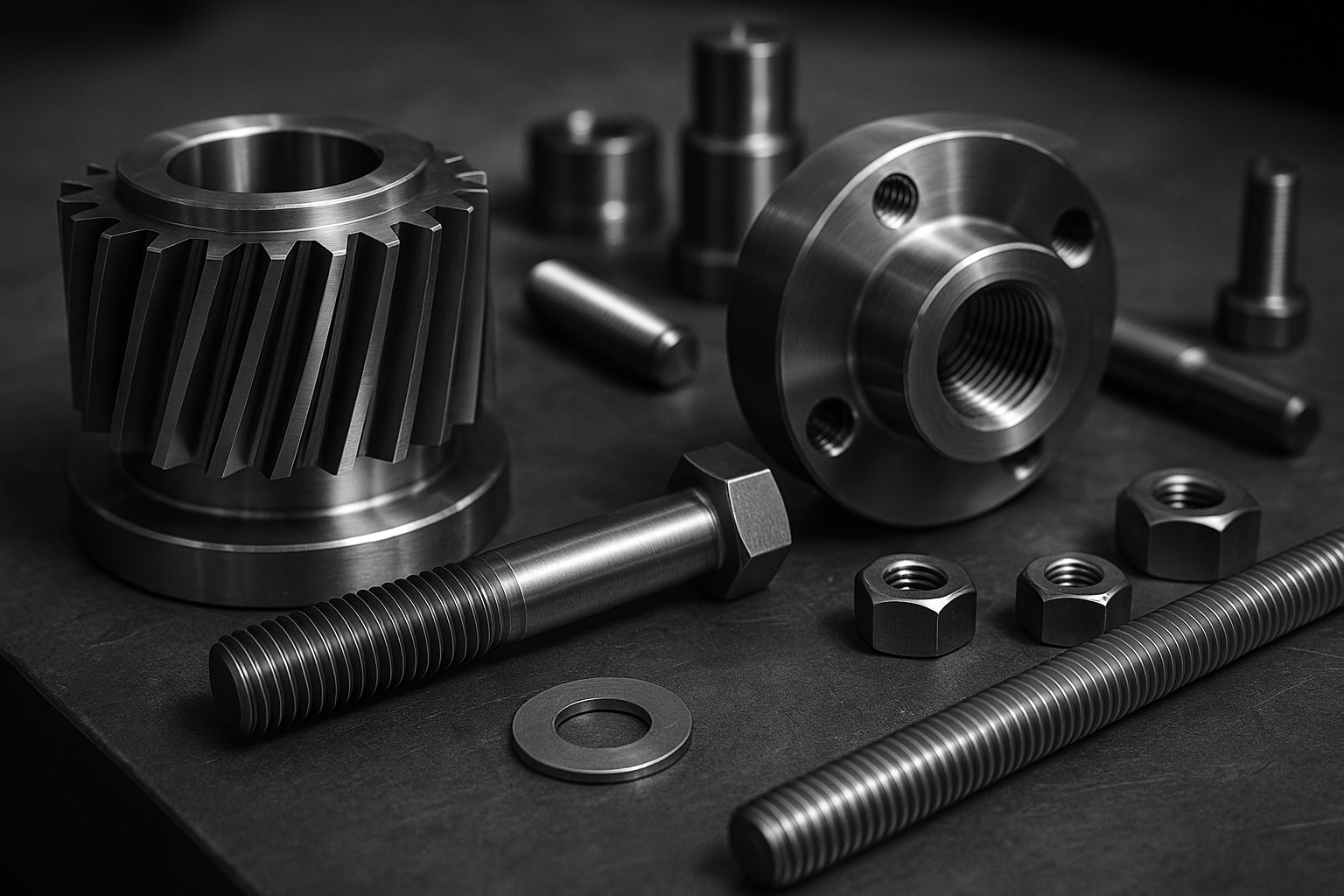

OEM precast accessories bridge this gap by combining industrial precision with standardized quality control. Manufactured in controlled environments and optimized through computer-aided design, these components deliver not only fit accuracy but also long-term performance reliability.

Principle: Engineering and Manufacturing Logic

At the core of OEM precast manufacturing lies the concept of precision replication. Instead of individually fabricated parts, a scalable mold-and-casting system is developed using digital simulation and CNC machining.

Key principles include:

-

Integrated CAD-to-mold workflow: Ensures dimensional fidelity between design and output.

-

Finite Element Analysis (FEA): Identifies optimal reinforcement and stress zones.

-

Surface treatment automation: Hot-dip galvanizing and epoxy coating extend corrosion resistance.

-

Tight tolerance control: Achieves ±0.3 mm deviation across batches, ensuring perfect assembly.

This integration minimizes waste, improves mechanical strength, and guarantees performance consistency even in mass production environments.

Comparative Performance Analysis

| Parameter | Conventional Accessories | OEM Precast Accessories |

|---|---|---|

| Manufacturing Tolerance | ±2–5 mm | ±0.3 mm CNC controlled |

| Surface Treatment | Manual or partial coating | Automated full coverage |

| Material Traceability | Limited batch tracking | Full digital traceability |

| Load Consistency | Varies per batch | Uniform under testing |

| Installation Accuracy | Requires rework | Plug-and-fit with embedded fittings |

Unlike traditional casting, OEM precast accessories integrate precision molds, monitored curing conditions, and automated surface finishing—delivering repeatable quality with measurable gains in strength and alignment.

Core Advantages and Engineering Value

1. Repeatable Accuracy

OEM-controlled production enables consistency across thousands of identical units, ensuring flawless structural integration.

2. Extended Durability

Coated and tested for tensile, compression, and corrosion resistance, each accessory exceeds standard performance metrics by up to 30%.

3. Material and Energy Efficiency

Optimized mold design reduces material waste during casting, while automated curing minimizes energy consumption by 20–25%.

4. Seamless Structural Integration

Embedded fittings and precision anchors ensure compatibility with architectural and civil elements without secondary machining.

5. Compliance and Global Standards

All Jingle precast components comply with EN 13369, ASTM C150, and ISO 9001, enabling deployment in international infrastructure projects.

Application Scenarios: From Infrastructure to Architecture

-

Bridge Deck Systems – OEM anchor blocks with reinforced steel inserts ensure stress continuity between sections.

-

Building Facades – Customized connection accessories provide seamless visual alignment with hidden structural support.

-

Utility Vaults and Drainage Systems – Heavy-duty fittings resist hydrostatic pressure and repeated installation cycles.

-

Industrial Foundations – Load-distribution plates and anchors maintain rigidity under vibration and machinery load.

These use cases show how OEM precast manufacturing transforms consistency into a competitive advantage—merging design flexibility with predictable performance.

Technical Selection Framework: Matching OEM Systems to Project Needs

To ensure the right choice of OEM precast accessories, project teams should assess five key technical dimensions:

-

Load Path Design: Define maximum dynamic and static loads to match reinforcement type.

-

Environmental Exposure: Choose surface treatment (galvanized, epoxy, or duplex) according to corrosion levels.

-

Dimensional Coordination: Align CAD models with BIM data for plug-and-fit assembly precision.

-

Tolerance Verification: Request inspection data per batch to maintain geometric consistency.

-

Lifecycle Value: Evaluate total ownership cost, not just initial unit pricing, to account for reduced rework and maintenance.

By applying these criteria, procurement and engineering teams can maximize ROI while ensuring compliance and structural safety.

Strategic Insight: OEM Customization as a Construction Multiplier

OEM precast accessories represent the intersection of precision manufacturing and scalable production. They eliminate unpredictable site conditions, accelerate installation, and guarantee fit accuracy—turning repeatable processes into measurable project efficiency.

At Jingle, we combine digital mold engineering, CNC manufacturing, and automated coating technology to produce OEM precast accessories that perform consistently under the toughest conditions. Each component is designed for alignment, strength, and sustainability—ensuring that every structure built with Jingle precision stands the test of time.

To explore OEM solutions tailored for your next project, visit our homepage or connect via our contact page for detailed consultation.