Engineering Consistency: How OEM Fastener Manufacturing Elevates Industrial Reliability

The Industrial Challenge of Precision and Repeatability

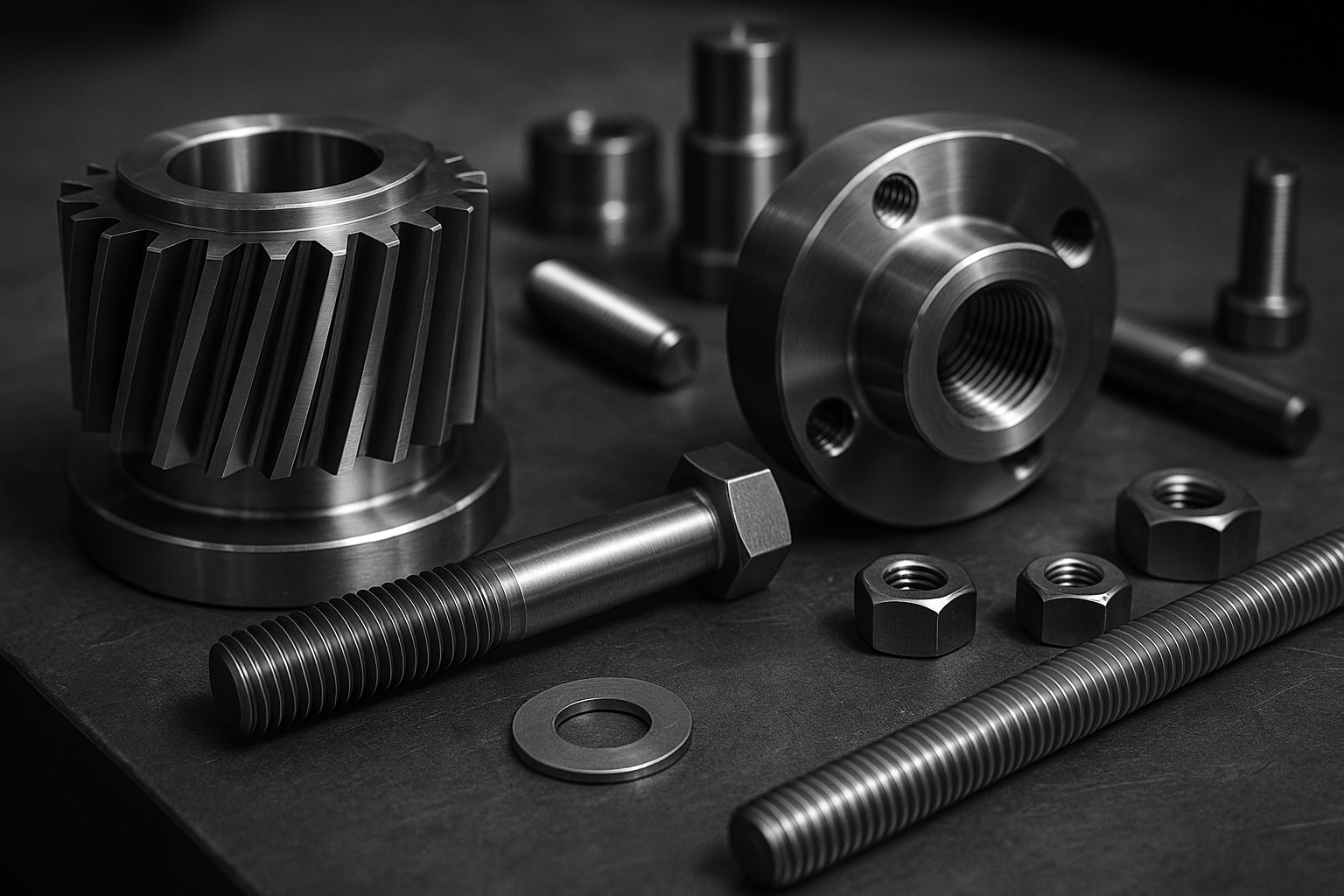

Across automotive, construction, and machinery industries, fasteners remain the smallest yet most critical components ensuring structural integrity. However, inconsistencies in production—ranging from thread tolerance errors to coating variations—can cause misalignment, fatigue failures, or premature corrosion.

OEM fastener manufacturing solves this by integrating precision design, material control, and automated production to achieve uniform performance across every batch. Instead of isolated manufacturing, it delivers engineered repeatability—the foundation of modern industrial reliability.

Principle: How OEM Fastener Manufacturing Works

OEM production relies on an end-to-end controlled process—starting from material selection to dimensional inspection and coating. Unlike conventional suppliers, OEM manufacturers such as Jingle combine automation with testing data to maintain consistency at micron-level precision.

Core engineering principles include:

-

CNC cold forging and rolling for consistent thread geometry and tensile strength.

-

Digital material traceability ensuring chemical and mechanical uniformity per batch.

-

Automated heat treatment that achieves hardness without compromising elasticity.

-

Advanced coating systems (zinc-nickel, Dacromet, hot-dip galvanization) improving corrosion resistance in harsh environments.

Through these technologies, OEM production ensures fasteners perform identically whether they are part of a car chassis, wind turbine, or precast structure.

Comparative Overview: Traditional vs. OEM Manufacturing

| Parameter | Traditional Fastener Production | OEM Fastener Manufacturing |

|---|---|---|

| Dimensional Tolerance | ±0.5 mm | ±0.05 mm CNC controlled |

| Material Verification | Manual batch testing | Automated real-time inspection |

| Surface Finish | Partial or uneven coating | Uniform 360° coating coverage |

| Strength Consistency | Moderate variation | Stable tensile range ±3% |

| Supply Scalability | Limited | Global OEM capacity with flexible customization |

Unlike mass-market manufacturing, OEM fastener production is process-certified and data-driven, ensuring traceable quality from material procurement to shipment.

Core Advantages and Engineering Value

1. Dimensional Integrity

Automated rolling and machining achieve consistent thread accuracy, ensuring perfect engagement in high-stress assemblies.

2. Material Optimization

Use of alloyed steel, stainless steel, and carbon variants ensures strength-to-weight balance and long-term resistance to stress corrosion.

3. Enhanced Durability

Protective coatings and uniform heat treatment provide up to 1,000-hour salt spray resistance, exceeding industry norms.

4. Scalable Customization

OEM facilities adapt tooling for specific sizes, pitches, and head configurations without affecting throughput—ideal for both high-volume and precision-critical projects.

5. Certified Global Compliance

Jingle’s production adheres to ISO 898-1, ISO 3506, ASTM A490, and DIN 933 standards, ensuring worldwide compatibility.

Industrial Applications Across Sectors

-

Automotive and Transportation – Precision bolts and nuts guarantee torque consistency in vehicle assemblies and chassis structures.

-

Energy and Power Systems – High-tensile fasteners secure turbines, solar mounts, and transformer housings against vibration stress.

-

Construction and Infrastructure – Galvanized anchor bolts and threaded rods ensure safe load distribution in steel frameworks.

-

Machinery and Equipment – OEM screws and washers deliver reliability in dynamic industrial systems.

Each application benefits from standardized performance, simplified installation, and extended service life under variable load conditions.

Professional Selection Framework: Evaluating OEM Fastener Systems

To ensure that selected fasteners align with technical and operational needs, engineers and buyers should evaluate using these five key dimensions:

-

Material Compatibility – Match steel grades or alloys to environmental exposure (e.g., carbon steel for dry areas, stainless steel for marine).

-

Mechanical Performance – Verify tensile, shear, and yield properties through test certification.

-

Surface Treatment Suitability – Select coatings based on humidity, temperature, and chemical exposure profiles.

-

Dimensional Precision – Ensure thread pitch and head configuration align with assembly torque requirements.

-

Lifecycle Value Assessment – Compare total cost of ownership, considering reduced rework, warranty claims, and installation time.

By integrating these metrics into procurement and design, industrial teams secure not only fasteners—but system integrity.

Strategic Outlook: Why OEM Manufacturing Defines the Future of Fastening

Fasteners may be small, but in precision industries, they determine the strength of everything around them. OEM fastener manufacturing represents the shift from reactive quality control to predictive manufacturing intelligence—producing consistent, verifiable results at scale.

At Jingle, every fastener is engineered for precision, tested for endurance, and delivered with data-backed assurance. Our OEM facility integrates CNC cold forging, robotic coating, and automated inspection systems to ensure measurable quality across every batch.

To explore OEM fastener manufacturing solutions for your industrial projects, visit our homepage or reach out through the contact page for consultation and technical support.