OEM Fastener Solutions: What Distributors Can Customize

Distributors Want More Than Just Low Price

Global hardware distributors today aren’t just looking for low-cost fasteners—they’re seekingexclusive SKUs, consistent quality, and local compliance. With construction and manufacturing markets becoming more competitive, offering generic bolts with no differentiators is no longer enough.

But many distributors face the same pain points:

-

Limited controlover specifications and packaging

-

Lack of documentationfor local certifications

-

Long lead timesfrom factories without OEM workflows

-

Zero flexibilityfor regional coating or plating preferences

That’s where an experienced OEM supplier likeJINGLEchanges the game.

What Can Be Customized in a Fastener OEM Program?

At JINGLE, our OEM/ODM service isn’t just about adding your logo. It covers every level of product customization, starting with:

1. Technical Specifications

We support bolt/nut/thread configurations for specific machinery, structural standards (e.g. DIN, ASTM, ISO), and end-market needs. This includes:

-

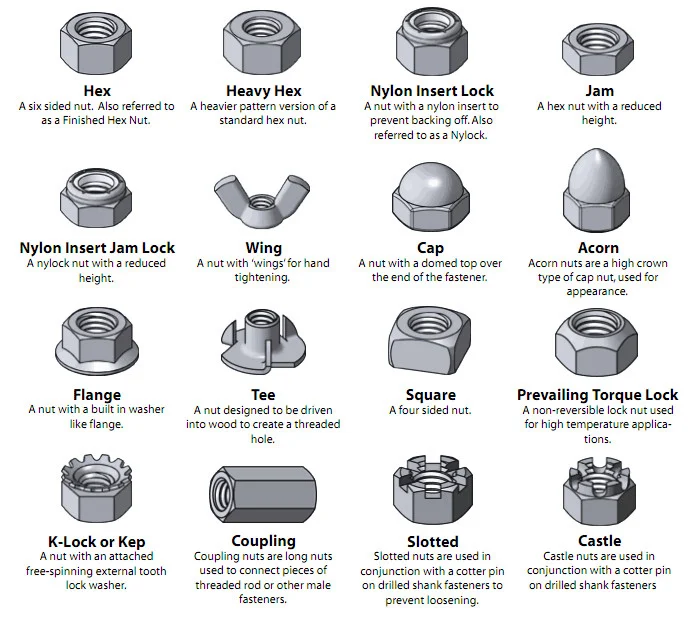

Head shape and drive type

-

Thread pitch and tolerance

-

Shaft or shank modifications

-

Coated finishes (HDG, Dacromet, black oxide, etc.)

Example: For a distributor in Brazil, we adjusted flange bolt dimensions to match old infrastructure sizes no longer mass-produced.

2. Materials and Performance

OEM clients can requestcarbon steel, stainless, alloy grades, or corrosion-resistant combinations, along withheat treatment options. Each batch comes with material test certificates.

3. Branding and Packaging

JINGLE enables full private labeling, including:

-

Box design with barcodes and SKU naming

-

Bulk or retail-style packaging

-

Country-of-origin labeling

-

Instruction manuals or diagrams

For European clients, we also prepareCE documentationand REACH-compliant data sheets.

Why OEM Fastener Services Are Growing in Demand

According to a 2024 report by Global Industry Analysts,the OEM fastener market is expected to reach $128.9 billion by 2026, with distributor partnerships playing a key role.

OEM fasteners help distributors:

-

Build brand equitywith unique SKUs

-

Enter tender marketsrequiring project-specific specs

-

Reduce warranty claimsvia controlled quality

-

Expand marginsthrough private label ownership

And when working with a supplier like JINGLE, the path from spec to shipment is streamlined.

How JINGLE Supports Distributors as an OEM Partner

We understand that distributors need more than products—they need reliability, traceability, and flexibility. Here’s how we deliver:

-

Dedicated OEM project managerfor every partner

-

3D modeling supportto match or reverse-engineer competitor parts

-

MOQ flexibilityfor new trial SKUs

-

Short lead timeswith container-level batch tracking

-

Full export documentation, including packing lists, HS codes, and MSDS

Whether you’re expanding into new regions or launching your own product line, JINGLE provides both the hardware and the operational support you need.

Ready to Build Your Custom Fastener Line?

At JINGLE, we don’t just manufacture—we co-develop. Our OEM fastener services are designed for distributors who want to grow beyond commodity pricing into long-term market value.

To learn more about how we support your brand with fastener OEM solutions, explore ourhomepageorcontact us hereto start a conversation.