OEM Solutions in Precast Accessories: Meeting Non-Standard Project Demands

Why Non-Standard Precast Accessories Are Needed

Precast concrete systems are widely used in bridges, tunnels, commercial buildings, and urban infrastructure. While catalog accessories provide standardized anchors and inserts, many projects require non-standard solutions. Unique load requirements, unusual geometries, or site-specific conditions often mean that only OEM customized precast accessories can ensure proper fit and structural safety.

Common Non-Standard Challenges in Construction

Construction teams often face demands that push beyond standard accessory sizes and designs:

-

Special Anchoring Systems: Extra-long or heavy-duty anchors for bridges and tunnels.

-

Custom Lifting Inserts: Tailored to handle oversized panels or unusual load angles.

-

Material Adaptability: Stainless steel or galvanized finishes for marine or high-humidity environments.

-

Precision Requirements: Tight tolerances in connectors and couplers for modular construction.

-

Compliance Needs: Full certification to ISO and ASTM standards, with traceability for large-scale projects.

These requirements highlight why OEM precast accessories are central to project success.

Design Collaboration in OEM Precast Accessories

One of the greatest strengths of OEM precast accessories lies in the ability to collaborate closely with design teams from the earliest stages of a project. Instead of adapting existing catalog parts, engineers and manufacturers work together to create solutions that match structural drawings, load calculations, and safety requirements. This design-to-production approach ensures that every anchor, insert, or connector is optimized for its specific role. By reducing installation errors and avoiding costly rework, design collaboration turns accessories into integral components of the engineering process.

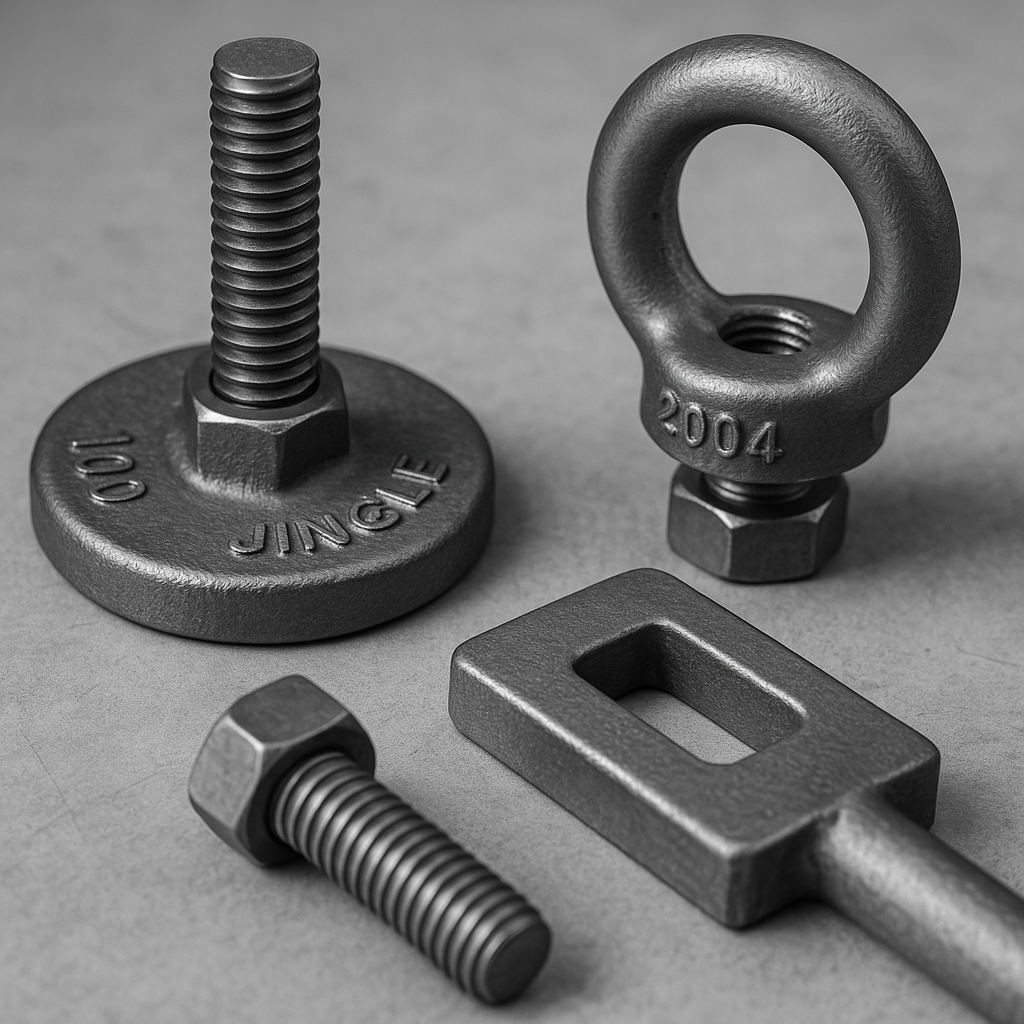

JINGLE’s Role in OEM Precast Accessories

As a professional precast accessories manufacturer, JINGLE supports engineering teams and distributors with comprehensive OEM capabilities:

-

OEM Customization: Tailored anchors, lifting inserts, connectors, and couplers designed to meet unique specifications.

-

Factory Strength: Large-scale production capacity, ensuring consistency and on-time delivery for bulk orders.

-

Certified Quality: ISO and CE compliance with in-house testing for load capacity, durability, and corrosion resistance.

-

Material Versatility: Steel, stainless steel, and other alloys adapted to harsh environments.

-

Global Supply: ERP-driven logistics with batch traceability, ensuring transparent supply chains for international projects.

With these strengths, JINGLE provides more than accessories—it delivers project-ready solutions.

Real Applications of OEM Precast Accessories

OEM precast accessories find vital applications across different construction sectors:

-

Bridge & Tunnel Projects: Heavy-duty anchors and couplers designed for unique load-bearing conditions.

-

Urban Buildings: Customized lifting systems to safely handle oversized precast panels.

-

Infrastructure Expansion: Non-standard connectors ensuring modular construction fits seamlessly.

-

Marine and Coastal Projects: Corrosion-resistant inserts supporting structures exposed to saltwater environments.

In each scenario, OEM customization ensures that construction projects move forward with efficiency, safety, and compliance.

Building the Future with Customized Reliability

Precast accessories may appear small in scale, but they carry enormous responsibility in shaping reliable infrastructure. Standard solutions cover the basics, yet non-standard OEM accessories are the true enablers of modern construction, adapting to new architectural designs, extreme site conditions, and ever-stricter compliance frameworks.

With its OEM expertise, certified factory production, and global delivery systems, JINGLE is positioned as more than a supplier—it is a partner helping the world’s most ambitious projects move from blueprint to reality.

Explore how JINGLE delivers OEM precast accessories tailored for non-standard demands: Contact JINGLE.