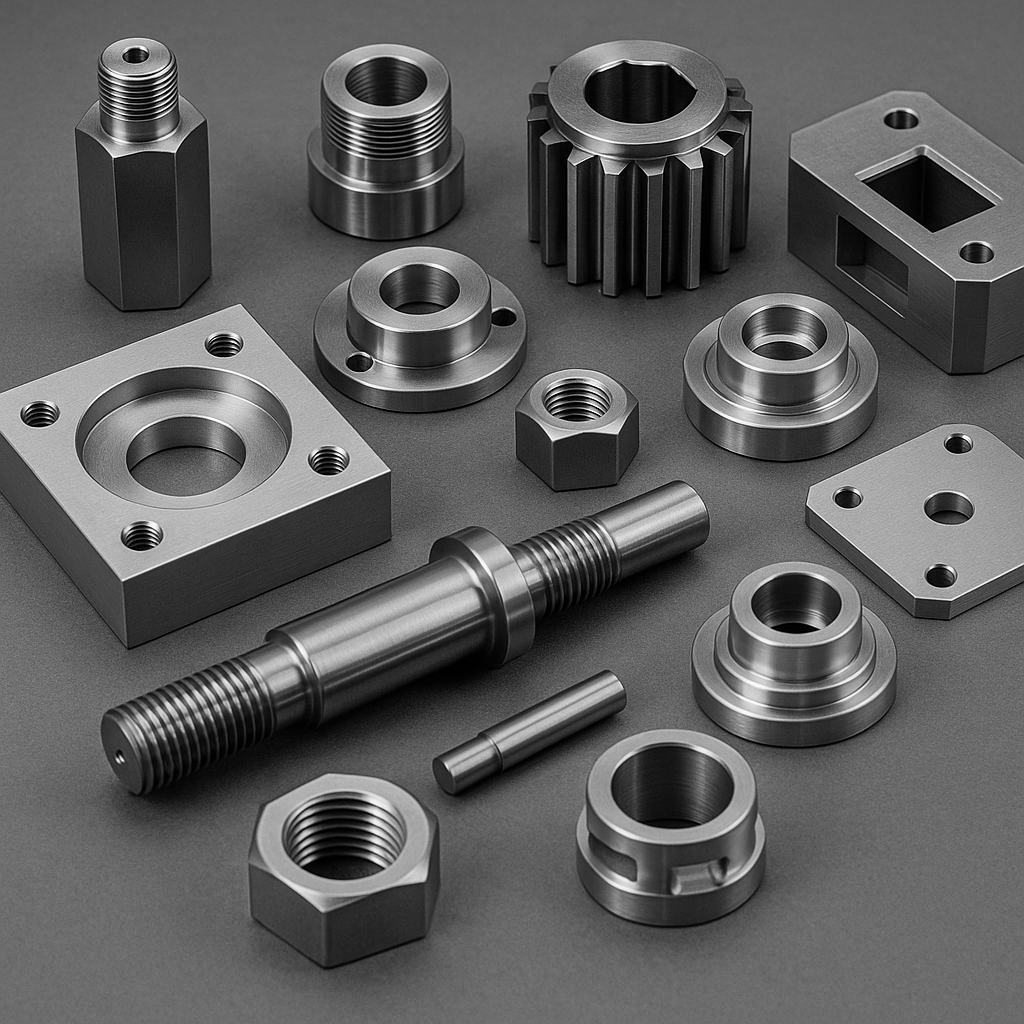

From Micro-Tolerances to Mass Production: What a Precision Components OEM Supplier Can Offer

Why Precision Components Define Industry Performance

In aerospace, automotive, and energy systems, precision components are the unseen foundation of performance. A single misalignment in a turbine blade, engine valve, or structural fastener can cause costly failures or safety hazards. The demand for components with micro-tolerance accuracy has never been greater, as industries push boundaries in speed, efficiency, and durability.

Challenges That Require OEM Precision Components

Global industries face challenges that make OEM suppliers indispensable:

-

Micro-Tolerance Accuracy: Even deviations within microns can impact performance in engines or high-speed systems.

-

Batch Consistency: Thousands of identical components must perform exactly the same to ensure reliability.

-

Material Engineering: Different environments require alloy steels, stainless steels, titanium, or specialized composites.

-

Lead Times and Scale: Projects depend on suppliers that can deliver both prototypes and mass orders without delays.

-

Certified Compliance: Meeting ISO and ASTM standards ensures traceability, safety, and approval for industrial use.

These challenges explain why OEM precision component suppliers are chosen over generic alternatives.

JINGLE’s Capabilities as a Precision Components OEM Supplier

As a professional OEM supplier of precision components, JINGLE combines factory capacity with engineering expertise to support global industries:

-

OEM Customization: Components tailored to exact specifications, covering size, materials, and finishes.

-

Certified Quality: ISO and CE compliance with in-house testing for tolerances, durability, and corrosion resistance.

-

High-Volume Manufacturing: Annual capacity enabling both small-batch prototypes and full-scale production.

-

Material Expertise: Skilled in machining steels, aluminum, stainless steel, and titanium for diverse applications.

-

Global Delivery: ERP-driven logistics with batch traceability, ensuring consistency from factory to project site.

This concentrated capability allows JINGLE to deliver not just parts, but confidence in every shipment.

Industry Applications of OEM Precision Components

Automotive Industry

In automotive manufacturing, precision components ensure engine efficiency, safety in braking systems, and reliability in suspension parts. OEM suppliers provide micro-tolerance consistency across mass production, helping reduce recalls and improving long-term performance.

Aerospace and Aviation

Aircraft components must balance lightweight design with absolute durability. OEM suppliers deliver titanium and alloy parts engineered to resist fatigue and extreme stress, ensuring compliance with strict aerospace safety standards.

Energy and Power Generation

From wind turbine gears to refinery valves, precision parts face constant vibration, high heat, and chemical exposure. OEM customization ensures materials and finishes are adapted to these demanding environments.

Heavy Machinery and Industrial Equipment

Mining and construction equipment rely on gears, shafts, and bearings that can endure shock and heavy loads. OEM suppliers provide durable parts that extend machine life and reduce costly downtime.

Rail and Transportation

High-speed rail systems require connectors and fasteners that can survive millions of vibration cycles. OEM suppliers guarantee accuracy and certification, enabling safe and efficient operation over decades.

Driving Industrial Reliability Through OEM Precision

Precision components may be small, but their impact on global industries is enormous. Standard catalog items cannot deliver the micro-tolerances, certified compliance, or large-scale consistency that modern projects demand.

With its OEM customization, certified manufacturing, and scalable capacity, JINGLE stands as a precision components supplier that ensures performance, safety, and long-term reliability.

Learn how JINGLE supports global industries with OEM precision components: Contact JINGLE