Precision Built to Last: How Professional Custom Hardware Parts Enhance Industrial Performance

The Hidden Foundation of Industrial Reliability

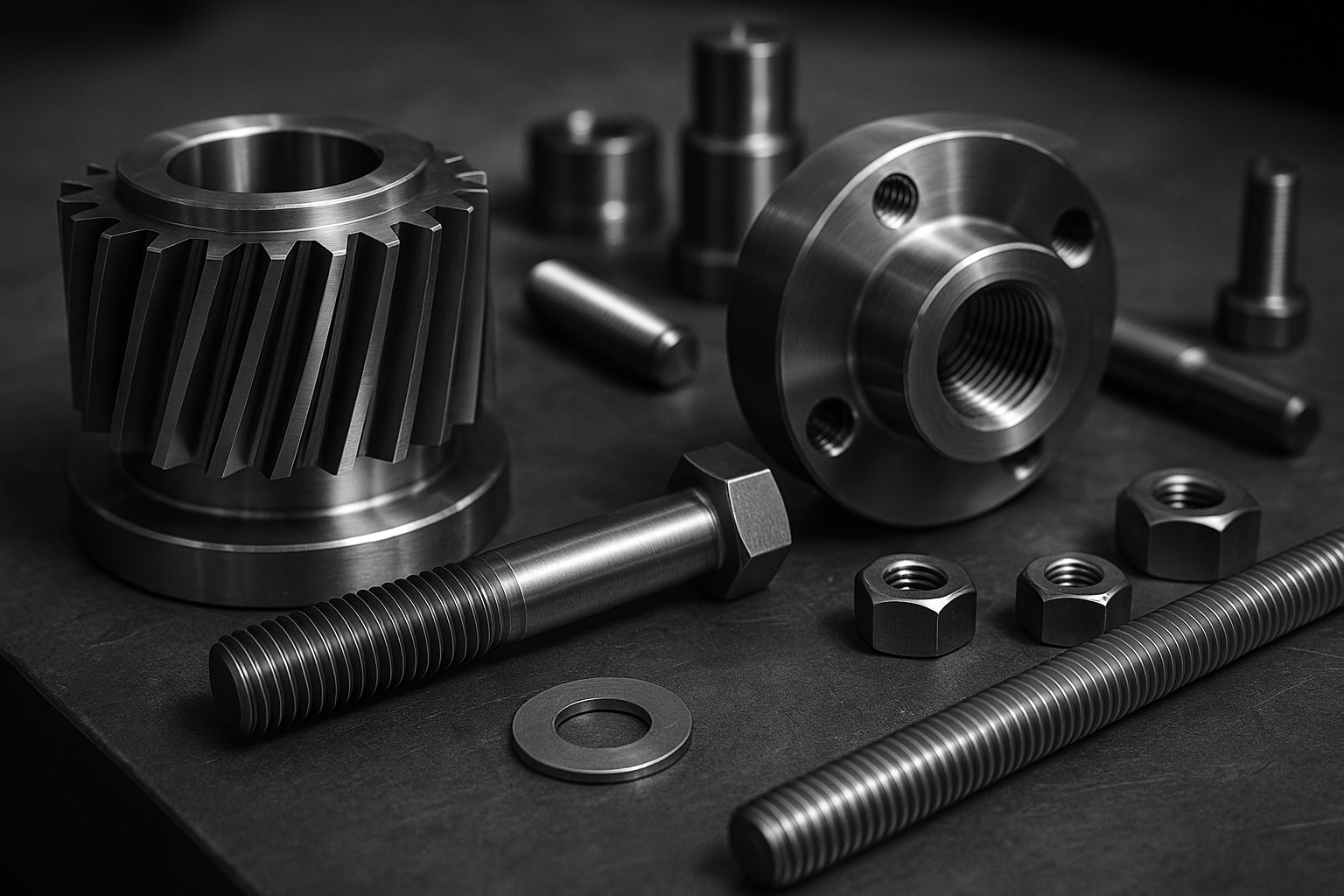

In every mechanical or structural system, hardware parts are the silent enablers that hold performance together. Yet when these parts fail—due to uneven coatings, poor machining, or dimensional drift—the entire assembly suffers. Downtime, inefficiency, and safety risks follow.

Professional custom hardware parts are designed to eliminate these issues. By integrating precision machining, tailored materials, and surface treatments, they deliver consistent fit and endurance across mechanical, architectural, and industrial environments.

Principle: Engineering Precision from Concept to Completion

Unlike standard off-the-shelf hardware, professional customization begins with engineering intent—how a part should behave under load, temperature, or motion.

Technical workflow includes:

-

3D modeling & tolerance mapping for accurate dimensional control.

-

CNC multi-axis machining ensuring sub-0.05 mm precision even in complex forms.

-

Material adaptation across aluminum, stainless, titanium, and carbon steel for diverse applications.

-

Functional coatings such as galvanization, nickel plating, or powder finish to match environmental needs.

This process transforms basic fittings into performance components—built not just to fit, but to last.

Standard Hardware vs. Professional Custom Components

| Specification | Standard Hardware | Professional Custom Hardware |

|---|---|---|

| Precision | ±0.5 mm | ±0.05 mm |

| Material Grade | Generic steel | Application-specific alloy |

| Surface Finish | Uncontrolled | Coated for corrosion, abrasion, or aesthetics |

| Load Reliability | Varies | Tested under dynamic loads |

| Design Adaptability | Limited | Fully adaptable to structural geometry |

Precision differences at this scale are not cosmetic—they determine whether an assembly functions flawlessly or fails prematurely.

Core Advantages: The Technical and Operational Edge

1. Dimensional Consistency

Every part undergoes coordinate-measuring machine (CMM) verification, ensuring perfect repeatability across batches.

2. Optimized Material Science

Hardware is engineered to balance weight, hardness, and elasticity—improving both tensile strength and fatigue resistance.

3. Simplified Assembly and Maintenance

Accurate tolerances minimize friction and assembly time while improving mechanical stability.

4. Aesthetic and Functional Integration

Architectural hardware can combine structural strength with premium surface finishing for visible installations.

5. Verified Standards

All Jingle hardware parts meet ISO 9001, DIN, and ASTM certifications, supporting projects across construction, manufacturing, and energy sectors.

Applications: From Machinery to Architecture

-

Automation Systems – Custom mounts and brackets ensure alignment in robotics and conveyor systems.

-

Renewable Energy – Hardware withstands vibration and thermal cycling in solar and wind installations.

-

Construction and Infrastructure – Bolts, clamps, and anchors deliver long-term load-bearing safety.

-

Marine and Offshore – Corrosion-resistant components survive constant salt exposure.

-

Architectural Fixtures – Decorative fittings maintain appearance while sustaining heavy mechanical loads.

Each industry demands a different balance between material strength, precision, and environmental protection—customization enables that balance.

Professional Selection Guidance: Matching Hardware to Real-World Conditions

Selecting hardware is not just about dimensions—it’s about environmental fit, load type, and maintenance lifecycle. Below is a professional framework for common industrial and construction scenarios:

| Scenario | Recommended Material | Surface Treatment | Design Focus |

|---|---|---|---|

| Outdoor Construction / Bridges | Hot-dip galvanized steel | Zinc or duplex coating | Long-term corrosion resistance and high load capacity |

| Precision Machinery / Robotics | Alloy or stainless steel | Electroplated or polished | Dimensional stability and vibration control |

| Marine / Offshore Equipment | 316 stainless or duplex steel | Epoxy or ceramic coating | Resistance to saline corrosion and fatigue |

| Architectural Applications | Aluminum or brass | Anodized or powder-coated | Visual quality with lightweight strength |

| Renewable Energy Systems | Carbon or alloy steel | Dacromet / zinc-nickel | Durability under constant vibration and UV exposure |

Professional insight:

-

When choosing for vibration-heavy environments (e.g., wind turbines, machinery), prioritize tensile flexibility over static strength.

-

For visible installations, coating uniformity and color stability should be prioritized over raw strength.

-

In corrosive zones, sealing threads and post-treatment passivation often add years to lifecycle.

By adapting selection criteria to actual conditions, engineers ensure optimal reliability without overspecification or unnecessary cost.

Engineering Hardware as a Competitive Advantage

In modern industry, precision hardware has evolved from a supporting role to a defining element of performance. It determines not only assembly speed but also operational longevity, energy efficiency, and maintenance cost.

At Jingle, professional customization merges CNC machining, surface engineering, and OEM-standard quality control to create hardware that performs beyond expectation. Every component is tested, traceable, and designed to integrate seamlessly with complex systems.

Explore how precision-built hardware can enhance your projects by visiting our homepage or reaching our engineering team through the contact page.