The Challenge of Secure Lifting in Construction Projects

In the fast-paced world of construction and heavy industry, ensuring the safe and efficient lifting of precast concrete elements is a critical challenge. One common issue arises when teams struggle with inadequate anchoring systems that fail under load, leading to delays, safety hazards, and costly rework. The lifting anchor emerges as a vital component in this scenario, designed to provide a reliable connection point for hoisting heavy loads without compromising structural integrity. Without a robust lifting anchor, projects can face risks like slippage or breakage, emphasizing the need for specialized solutions that address these vulnerabilities head-on.

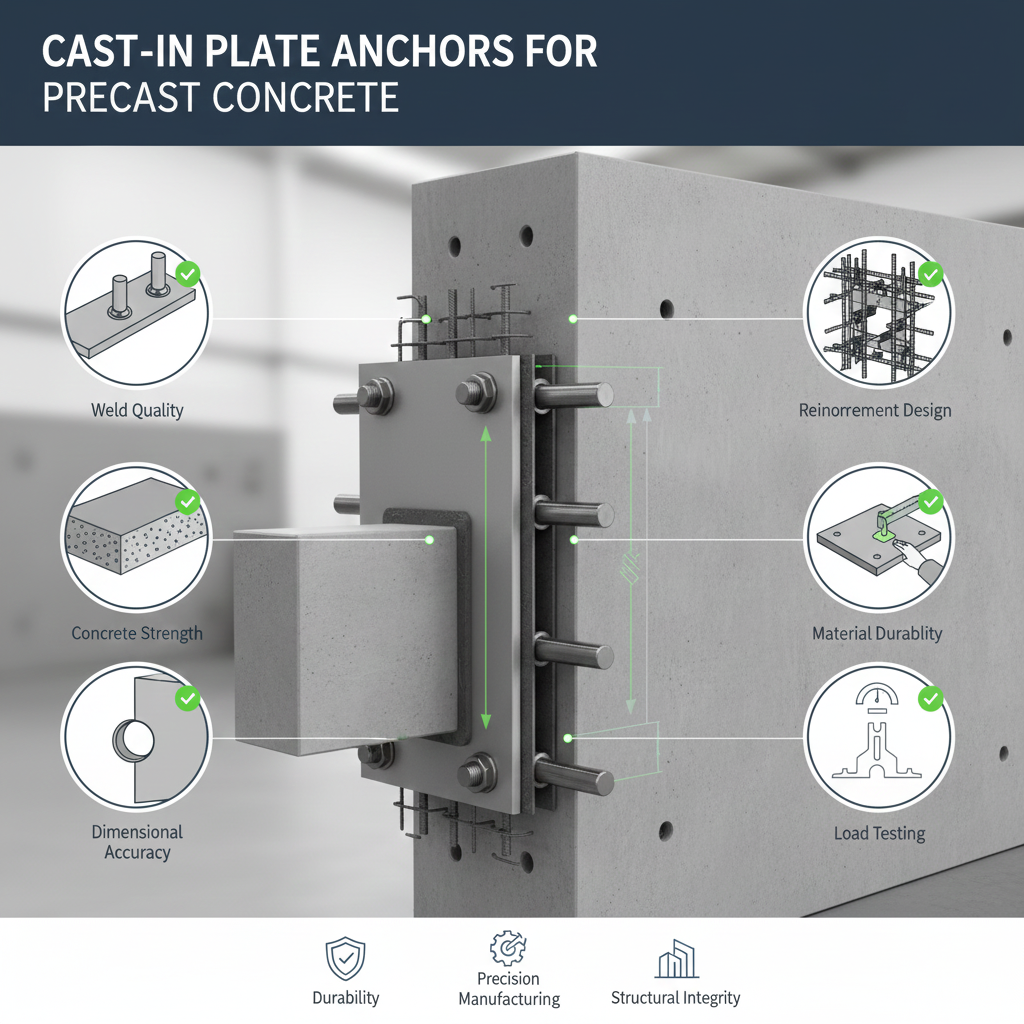

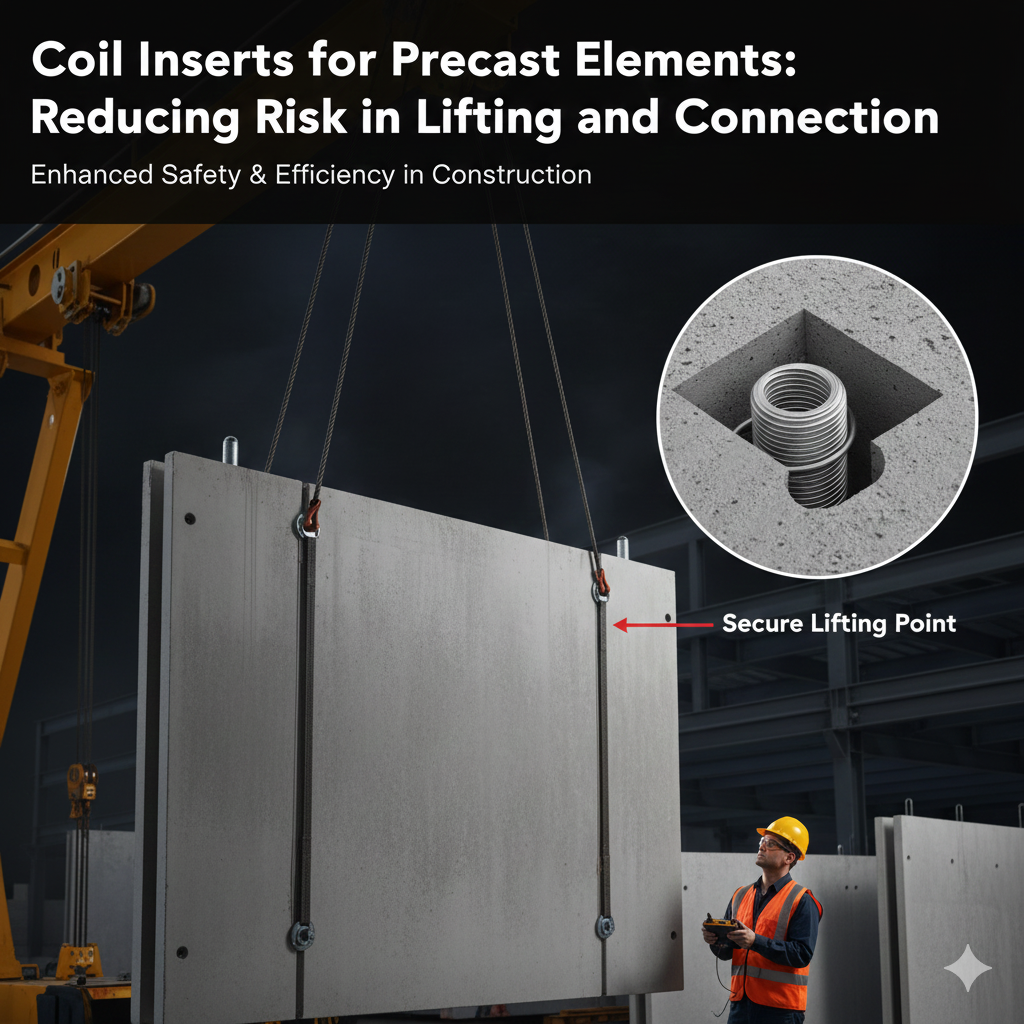

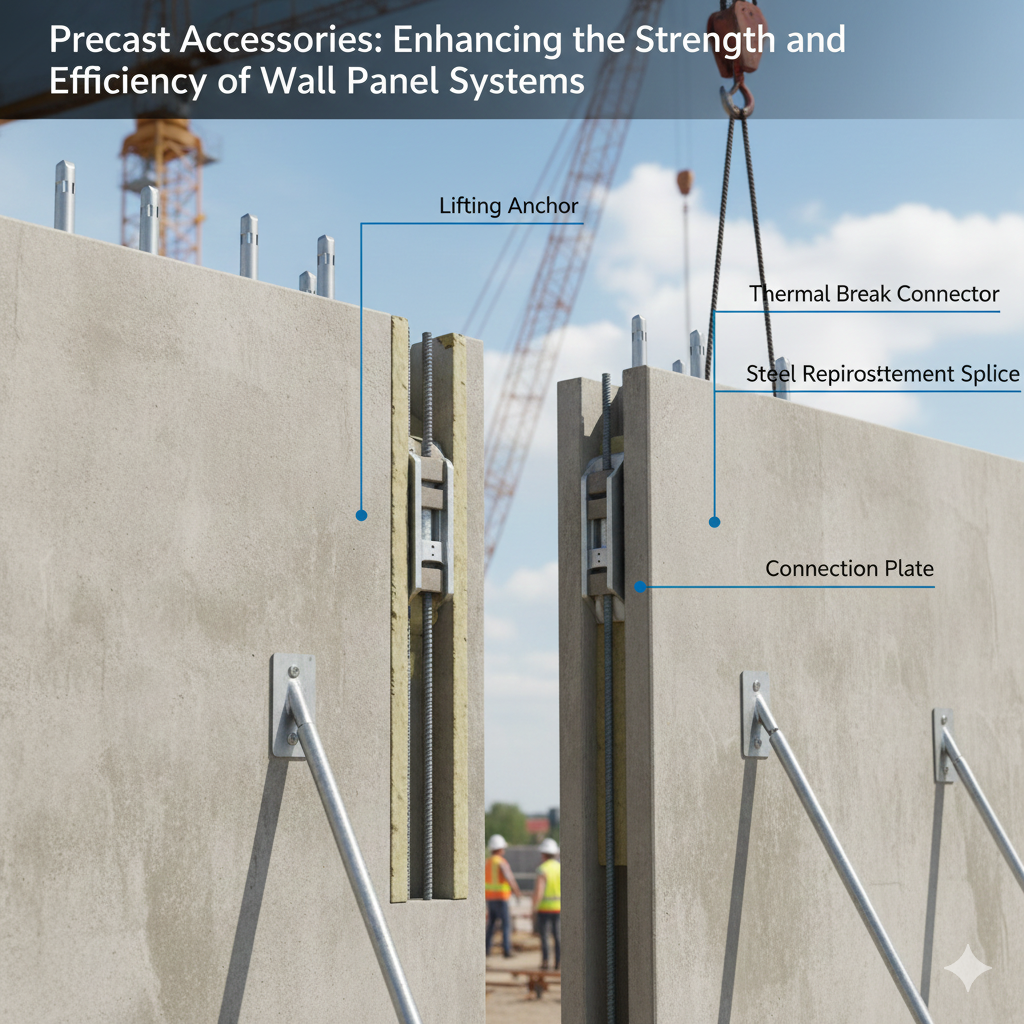

Understanding the Role of Lifting Anchors

Lifting anchors are embedded hardware pieces typically made from high-strength steel, inserted into concrete during the casting process to facilitate secure lifting. The problem intensifies in environments where variable loads and harsh conditions test the limits of standard fasteners, often resulting in inefficient operations or accidents. To counter this, modern lifting anchors are engineered with features like corrosion resistance and high load capacities, allowing for precise and safe elevation of slabs, beams, and panels. By integrating these anchors early in the design phase, construction teams can mitigate risks associated with manual handling or improvised lifting methods, streamlining workflows and enhancing overall project safety.

Enhancing Efficiency with Lifting Clutches

A key companion to the lifting anchor is the lifting clutch, which locks onto the anchor's head to form a temporary but secure attachment for cranes or hoists. The frequent problem of mismatched or worn-out clutches leads to unreliable grips and potential load drops, disrupting operations and increasing downtime. Lifting clutches solve this by offering quick-release mechanisms and compatibility with various anchor sizes, ensuring a seamless connection that withstands dynamic forces during lifts. These devices are often color-coded for load ratings, making it easy to select the right one for the job, thereby reducing errors and boosting productivity on site.

Implementing Solutions for Long-Term Reliability

To fully address lifting challenges, it's essential to adopt a comprehensive system that pairs lifting anchors with compatible lifting clutches. Problems like anchor protrusion or clutch misalignment can be resolved through proper installation guidelines and regular inspections, preventing failures before they occur. For instance, using void formers around anchors minimizes concrete waste, while training programs ensure workers handle clutches correctly. This problem-solution approach not only cuts costs by avoiding accidents but also complies with industry standards like those from OSHA or EN regulations. By prioritizing these tools, companies can transform potential hazards into efficient, reliable lifting operations that keep projects on track and teams protected.

Best Practices for Selecting and Using Lifting Systems

When choosing lifting anchors and clutches, consider factors such as load requirements, environmental exposure, and ease of reuse. The recurring issue of over-specification or underestimation of capacities can lead to unnecessary expenses or safety oversights. Opt for systems from reputable manufacturers that provide detailed load charts and testing certifications to ensure compatibility. Regular maintenance, including cleaning clutches after each use, extends their lifespan and maintains performance. Ultimately, integrating these solutions fosters a proactive stance against lifting problems, promoting safer, faster construction processes that deliver results without compromise.