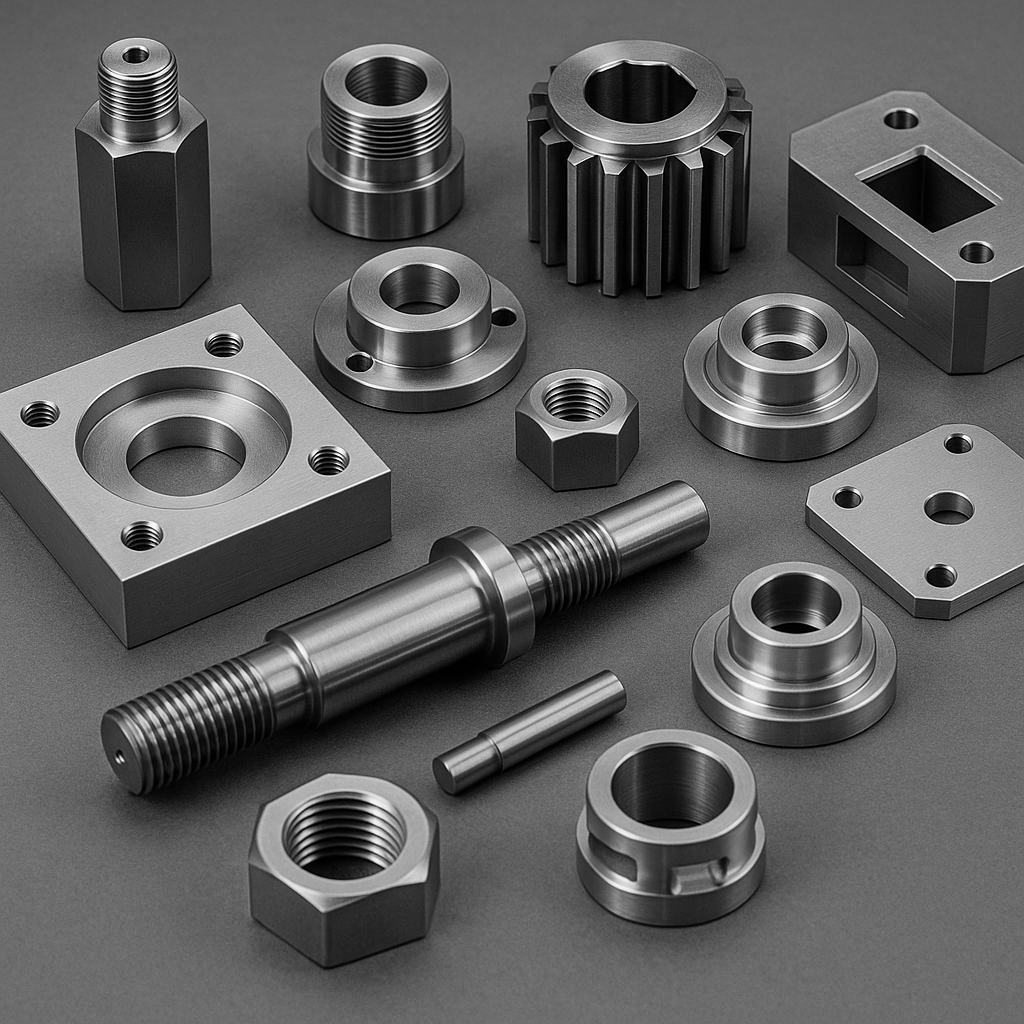

Precision in Motion: CNC Part OEM Production for Modern Manufacturing

The Growing Demand for Precision and Consistency

Global manufacturers face increasing pressure to deliver complex components with zero tolerance for deviation. Standardized production often struggles to balance accuracy, scalability, and material efficiency. In fields such as aerospace, automotive, and industrial automation, even a 0.1 mm error can cause assembly failure or performance loss.

CNC part OEM production offers the solution—combining high-precision machining with full-process integration. By aligning digital design and real-time process control, it ensures every component performs precisely as engineered.

Principle: The Engineering Logic Behind CNC OEM Production

CNC OEM manufacturing differs from conventional subcontract machining by integrating design-to-delivery control. It’s a systemized process built around data, automation, and material optimization.

Key engineering elements include:

-

CAD/CAM integration: Ensures toolpaths directly reflect engineering designs.

-

Multi-axis machining: Enables complex geometries and undercuts without multiple setups.

-

Real-time feedback loops: AI sensors monitor tool wear and maintain precision.

-

Material traceability systems: Guarantee consistency across global production batches.

Together, these ensure high tolerance accuracy, minimal waste, and repeatable results—essentials for long-term OEM partnerships.

General CNC Machining vs. OEM-Grade Production

| Parameter | General CNC Machining | CNC Part OEM Production |

|---|---|---|

| Tolerance Accuracy | ±0.05–0.1 mm | ±0.005–0.01 mm |

| Batch Consistency | Manual control | Digital calibration with automated feedback |

| Toolpath Optimization | Fixed program | Adaptive real-time optimization |

| Material Certification | Partial traceability | Full lot-level documentation |

| Production Efficiency | Single project focus | Continuous large-scale runs |

OEM-grade CNC manufacturing is not about one-off precision—it’s about repeatable precision at industrial scale.

Core Advantages: How CNC OEM Manufacturing Creates Value

1. Dimensional Stability at Scale

Each part is verified by coordinate measuring machines (CMM) to ensure micron-level accuracy across thousands of units.

2. Cost Efficiency Through Process Optimization

Adaptive feed rates and tool management systems reduce cycle time by up to 25% without compromising accuracy.

3. Material Utilization and Sustainability

Optimized nesting and chip recycling processes lower material waste by 15–20%, supporting sustainable production practices.

4. Seamless Design Collaboration

OEM workflows allow clients to integrate CAD data directly with production planning, reducing engineering iterations.

5. Certified Quality Assurance

All Jingle CNC parts comply with ISO 9001, ISO 2768, and DIN 7168 standards, with comprehensive inspection reports per batch.

Application Scenarios: From Prototype to Production Scale

-

Automotive Powertrain Systems – Precision shafts, housings, and brackets ensure transmission and engine efficiency.

-

Aerospace Components – Lightweight aluminum and titanium parts maintain flight safety and performance.

-

Robotics and Automation – High-tolerance joints and connectors improve motion stability and response speed.

-

Medical Equipment – CNC-machined stainless and polymer components guarantee sterilization safety and bio-compatibility.

-

Industrial Tooling – Hardened steel parts maintain durability under repetitive load cycles.

These applications highlight CNC OEM manufacturing’s ability to support both prototyping and full-scale production with consistent reliability.

Professional Selection Guidance: Matching CNC Processes to Application Requirements

Choosing the right CNC production method depends on design complexity, batch volume, and material type. The following chart summarizes typical scenarios:

| Application Type | Recommended Machining Process | Material Category | Notes |

|---|---|---|---|

| High Precision / Small Batch | 5-axis CNC milling | Aluminum / Titanium | Ideal for aerospace and medical parts |

| Mass Production | CNC turning + milling center | Alloy / Carbon steel | Best for automotive components |

| Complex Geometry | Multi-axis simultaneous machining | Aluminum / Brass | Enables curved and undercut designs |

| Heavy-Duty Use | CNC lathe + grinding | Stainless / Hardened steel | Ensures strength and fatigue resistance |

| Rapid Prototype Development | Hybrid machining + 3D CAD integration | Aluminum / Polymer | Accelerates design validation |

Expert insights:

-

For lightweight design, use aluminum alloys with anodized coatings to reduce corrosion and mass.

-

In dynamic load systems, ensure rotational symmetry to avoid vibration and imbalance.

-

Always request PPAP or FAI (First Article Inspection) documentation for critical assemblies.

Strategic Perspective: CNC OEM Production as a Competitive Advantage

Precision manufacturing defines the competitive edge of every industrial system. CNC part OEM production transforms isolated machining into a connected ecosystem—one where digital design, machine intelligence, and global quality control converge.

At Jingle, our OEM machining solutions integrate multi-axis precision, automated inspection, and real-time process monitoring to ensure every component delivers measurable reliability.

Explore how our CNC OEM production services can elevate your manufacturing performance by visiting our homepage or contacting our engineering team through the contact page.