From Specification to Supply: Engineering Fastener Procurement in Modern Manufacturing

The Evolution of Fastener Procurement in Engineering

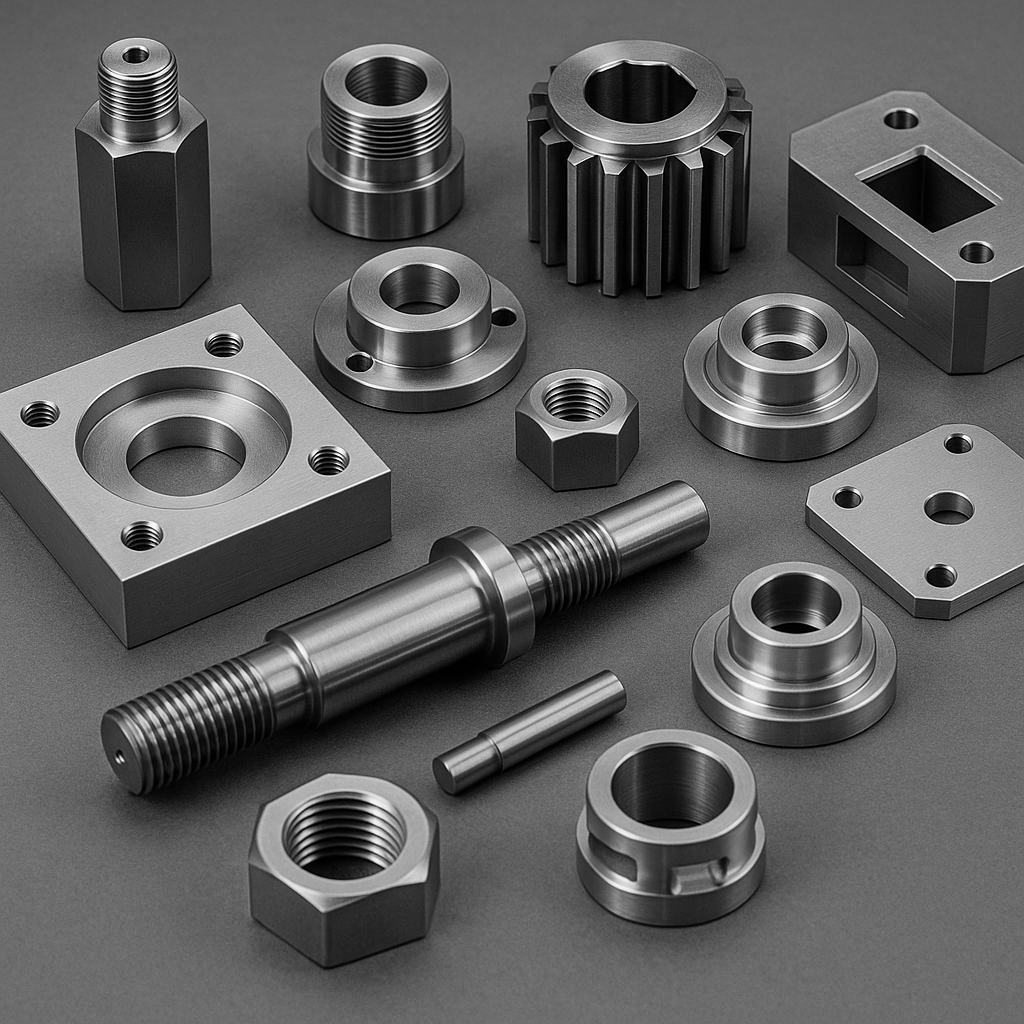

Behind every reliable structure lies an often-overlooked foundation—fasteners engineered for precision and longevity. Yet as product design grows complex, procurement teams face a delicate balance: maintaining mechanical integrity while controlling costs, materials, and logistics.

In traditional procurement, decisions were driven by price or availability. Today, engineering-driven industries prioritize traceable quality, specification alignment, and lifecycle performance. This shift transforms procurement from a purchasing task into a strategic engineering function—where every bolt, nut, and washer contributes to overall system reliability.

Data and Design Integration in Modern Sourcing

Engineering procurement begins long before parts reach the assembly line. Modern supply models integrate design data, material standards, and digital verification from the earliest stage.

Key principles include:

-

CAD-linked sourcing: Ensures fasteners match digital design tolerances and load models.

-

Material certification control: Verifies tensile, yield, and hardness properties before shipment.

-

Batch traceability: Every lot is identified by heat number and material origin.

-

Predictive logistics: Uses data to forecast lead times, preventing production downtime.

This framework transforms procurement into a closed feedback loop—where engineering and supply chain decisions reinforce each other.

Conventional vs. Engineering-Based Fastener Procurement

| Parameter | Conventional Procurement | Engineering-Based Procurement |

|---|---|---|

| Decision Basis | Cost and availability | Load requirement + performance metrics |

| Material Verification | Supplier-provided | Certified tensile and corrosion testing |

| Traceability | Limited | Full heat and batch documentation |

| Inventory Control | Manual | Digital ERP/MES integration |

| Design Alignment | Reactive (post-failure) | Preventive (based on CAD/FEM analysis) |

Engineering procurement ensures that fasteners are not just parts—but verified structural elements tailored to each project’s mechanical design.

Engineering-Driven Procurement Efficiency

1. Reliability Through Material and Process Control

With complete documentation and mechanical test data, engineers can validate that fasteners meet all design and load criteria before installation.

2. Cost Predictability Through Lifecycle Analysis

By evaluating material fatigue and coating longevity, long-term costs decrease—even if unit prices are slightly higher upfront.

3. Standardization Across Production

OEM-based part coding allows identical fasteners to be used across multiple platforms or facilities, improving inventory efficiency.

4. Supplier Collaboration and Quality Auditing

Partnerships with verified OEM suppliers like Jingle ensure inspection routines, torque verification, and coating integrity are consistently maintained.

5. Global Logistics Consistency

By linking procurement systems with digital warehouses, delivery times shorten, and the risk of specification mismatch is eliminated.

When Procurement Impacts Engineering Outcomes

-

Automotive Assembly Lines – Lightweight bolts with torque traceability improve drivetrain and chassis stability.

-

Construction and Infrastructure – Pre-approved anchors and threaded rods prevent installation delays.

-

Renewable Energy Systems – Corrosion-proof fasteners support solar and wind installations under extreme conditions.

-

Industrial Automation – Precision screws reduce misalignment in robotic joints and servo mechanisms.

-

Aerospace Structures – Titanium fasteners maintain performance under temperature and vibration stress.

These cases show that procurement choices directly influence performance, warranty, and operational reliability.

Choosing the Right Procurement Framework

Selecting an engineering-grade fastener supplier requires a structured evaluation of mechanical, operational, and compliance needs.

| Requirement | Recommended Practice | Key Verification |

|---|---|---|

| Load-Bearing Applications | Select high-tensile steel (10.9–12.9 grade) | Tensile test & torque validation |

| Corrosive Environments | Use stainless steel (A2/A4) or duplex alloys | Salt spray test ≥ 720 hours |

| High Vibration Systems | Employ prevailing torque or self-locking designs | Thread-lock performance data |

| Safety-Critical Components | Source from OEM-certified suppliers | ISO 898 & EN 14399 documentation |

| Large Infrastructure Projects | Prioritize batch-standardized lots | Material heat traceability |

Expert Insight:

-

Always request First Article Inspection (FAI) before mass supply.

-

Confirm supplier compliance with ISO 9001 / IATF 16949.

-

Use digital supplier portals to link design changes directly with procurement specifications.

Turning Procurement into Engineering Assurance

In the era of digital manufacturing, fastener procurement has evolved from a transactional process to a technical discipline. Engineering-led sourcing ensures that every connection in a structure—mechanical or electronic—operates within defined performance boundaries.

At Jingle, our OEM procurement services integrate engineering design alignment, digital traceability, and precision manufacturing, helping enterprises secure their production chains with confidence.

Discover how Jingle’s engineering-driven procurement system supports global OEM projects—visit our homepage or reach out through our contact page.