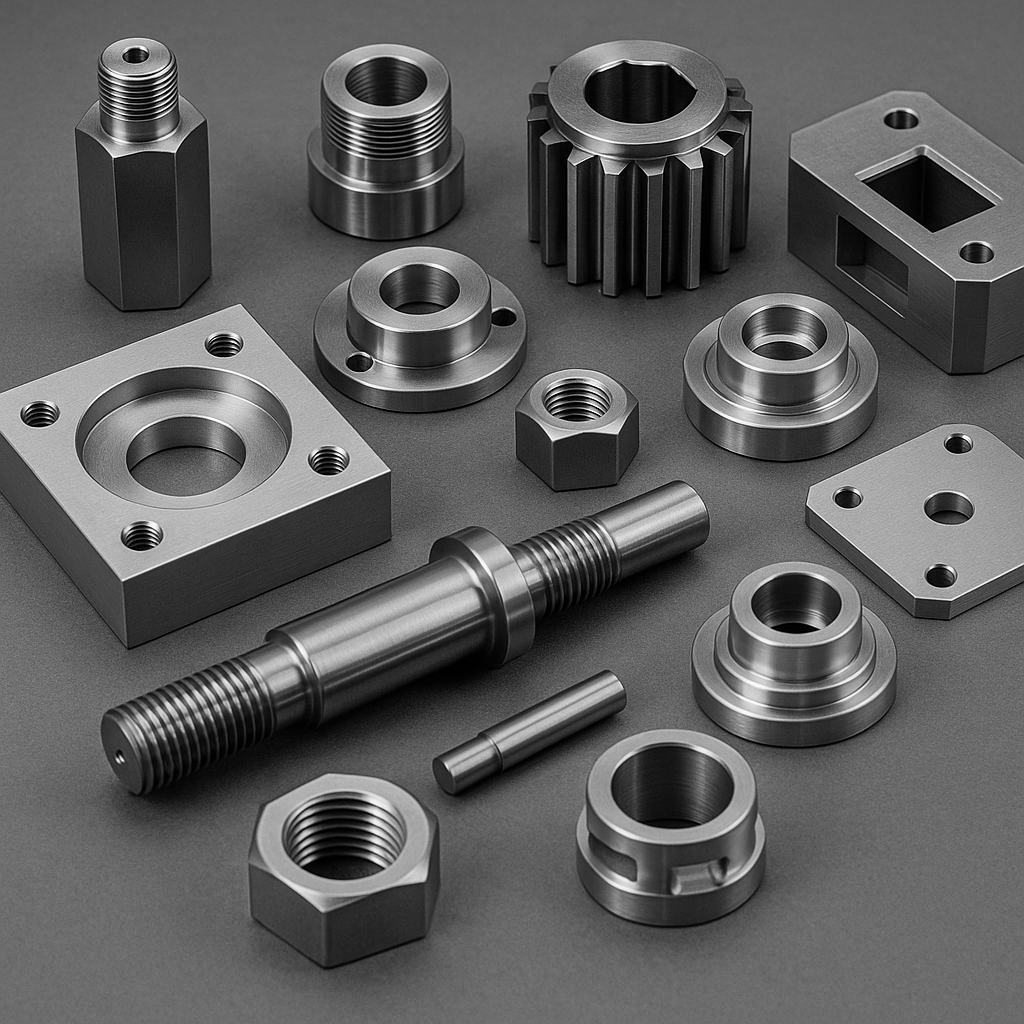

Building Strength in Every Detail: Metal Part Custom Supplier Solutions for Modern Manufacturing

Precision and Performance Redefined

Every industry—from automotive to heavy equipment—depends on components that perform consistently under mechanical stress. Yet, off-the-shelf hardware often fails to deliver the dimensional precision, surface finish, or strength required for complex assembly environments.

That’s why metal part customization has evolved into a core capability within modern OEM manufacturing. It provides the flexibility to engineer, test, and mass-produce components that meet the exact functional and environmental requirements of each application.

By combining CNC machining, material science, and digital inspection, suppliers like Jingle deliver parts that transform structural reliability into a measurable performance advantage.

Principle: Engineering Logic of Metal Part Customization

Custom metal parts are engineered not simply for form, but for functional integrity. The OEM customization process integrates precision design and controlled production to minimize variability and maximize efficiency.

Key elements of this process include:

-

CAD/CAM integration: Aligns design intent with real-time manufacturing control.

-

Multi-axis CNC machining: Enables intricate geometries and complex contours.

-

Material analysis: Selects alloys based on tensile strength, corrosion resistance, and weight requirements.

-

Quality mapping: Uses coordinate measuring systems (CMM) for micrometer-level verification.

This systematic approach ensures every part performs identically—batch after batch, year after year.

Standard Machining vs. OEM Custom Metal Production

| Parameter | Standard Metal Fabrication | OEM Custom Metal Part Production |

|---|---|---|

| Tolerance Accuracy | ±0.1–0.3 mm | ±0.01–0.05 mm |

| Material Options | Basic mild steel / aluminum | Stainless, brass, titanium, alloy steel |

| Surface Finish | Polished or untreated | Anodized, galvanized, powder-coated |

| Design Flexibility | Pre-set templates | Fully parametric customization |

| Batch Consistency | Manual QC | Automated 100% digital inspection |

The OEM method prioritizes process repeatability—a foundation for industrial-scale quality control.

Core Advantages: Why Custom Metal Parts Drive Industry Innovation

1. Enhanced Structural Integrity

Through precision machining and thermal stabilization, Jingle ensures every metal part maintains load-bearing reliability even under extreme mechanical stress.

2. Superior Surface Protection

Anodizing, powder coating, or galvanization provide corrosion resistance that extends service life in harsh industrial and marine environments.

3. Flexible Geometry Control

OEM customization supports multi-part integration, reducing component count and simplifying assembly lines.

4. Cost Optimization Through Efficiency

Adaptive machining reduces waste and setup time by up to 25%, achieving faster delivery without compromising precision.

5. Certified Quality Assurance

All parts conform to ISO 9001 and DIN 2768 standards with full inspection reports and traceable production records.

Application Scenarios: How Custom Metal Parts Fit Industrial Demands

-

Automotive & Transport Systems – Engine mounts, drive housings, and exhaust fittings designed for vibration resistance.

-

Industrial Machinery – Shafts, clamps, and structural connectors optimized for fatigue endurance.

-

Renewable Energy Systems – Corrosion-resistant components supporting solar and wind installations.

-

Construction & Infrastructure – Heavy-duty fasteners and fixtures improving load distribution.

-

Electromechanical Assemblies – Compact housings and thermal control parts for automation devices.

Each scenario benefits from OEM customization’s ability to combine durability, repeatability, and integration efficiency.

Professional Selection Framework: Choosing the Right Custom Metal Supplier

Choosing a supplier requires aligning engineering scope, volume scale, and performance requirements.

| Project Type | Recommended Material | Key Focus | Machining Process |

|---|---|---|---|

| Automotive Parts | Alloy steel / aluminum | Strength-to-weight ratio | CNC milling + surface treatment |

| Construction Hardware | Galvanized steel | Corrosion and load resistance | CNC cutting + hot-dip coating |

| Energy Equipment | Stainless steel / titanium | Corrosion + temperature endurance | Precision turning + polishing |

| Automation Systems | Brass / aluminum | Dimensional control | Multi-axis CNC + laser finishing |

| Marine Components | Duplex stainless steel | Salt resistance | CNC + powder coating |

Engineering advice:

-

Request prototype samples for stress and tolerance validation before mass production.

-

Ensure suppliers use real-time SPC (Statistical Process Control) to maintain dimensional stability.

-

For export projects, verify RoHS and REACH compliance for coatings and materials.

Custom Metal Parts as an Industrial Backbone

As industries transition to automation and sustainable engineering, custom metal components will define the foundation of efficiency and innovation. They enable manufacturers to replace standard parts with performance-specific solutions, reducing downtime and improving product lifecycle reliability.

At Jingle, we deliver OEM-grade metal part customization that integrates design precision, advanced machining, and global logistics.

To learn how Jingle’s custom metal manufacturing can strengthen your next project, visit our homepage or contact our engineering team through the contact page.