Precision Built: Precast Part OEM Customization for Structural Reliability

Reimagining Consistency in Structural Components

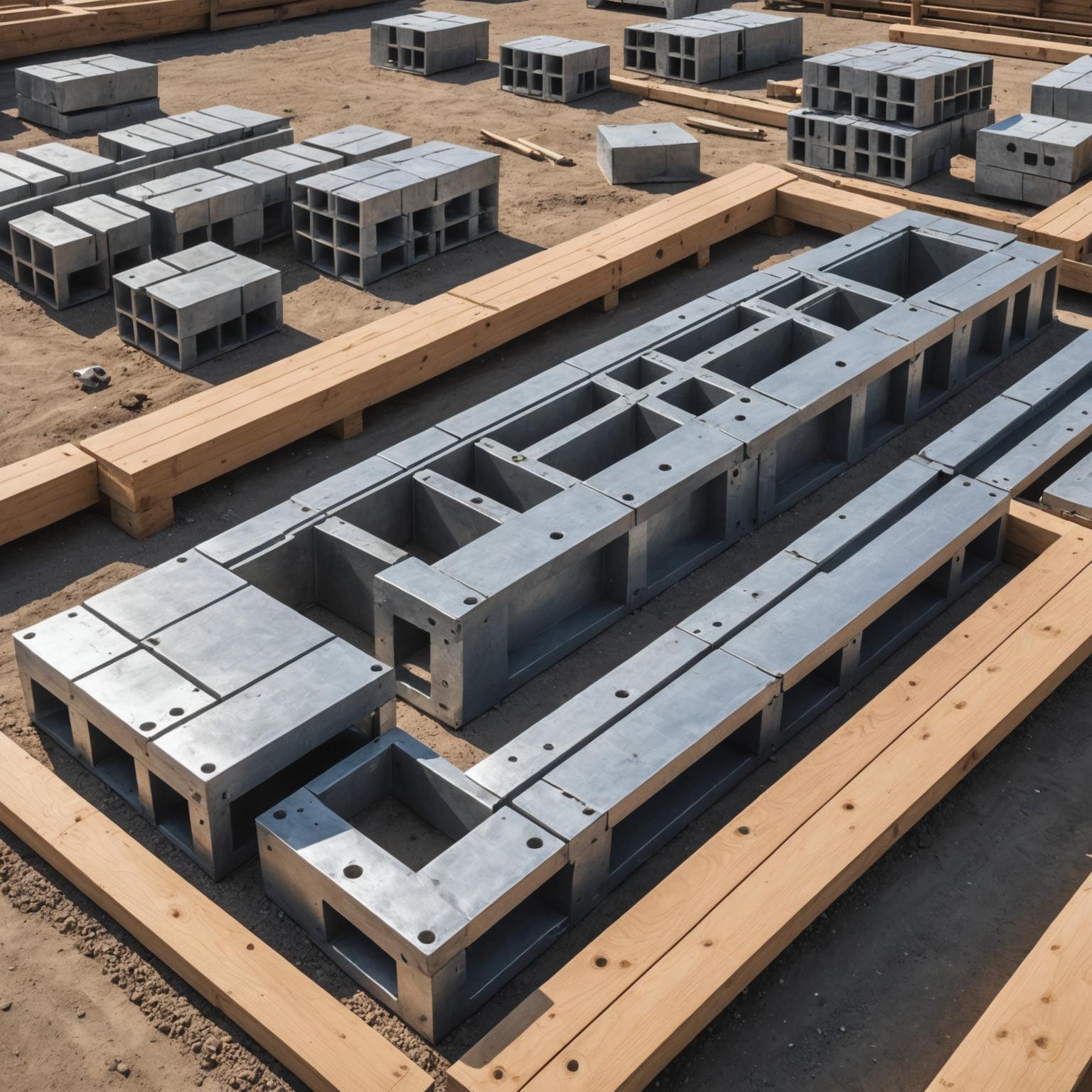

Modern construction requires precision that extends beyond design blueprints. From bridges and tunnels to building façades, precast parts are expected to maintain dimensional accuracy, weather resistance, and rapid installation compatibility. Yet, conventional sourcing often introduces inconsistencies—variations in molds, finishes, or reinforcement quality—that can delay assembly and increase project cost.

Precast part OEM customization resolves these issues by merging engineering control with scalable production. Through advanced mold design, material standardization, and automated casting, each component is produced to match exact project specifications—ensuring fit, finish, and function align seamlessly on-site.

Engineering Logic Behind OEM Precast Customization

Unlike general precast supply, OEM-level customization operates on design integration and controlled reproducibility. Each step—from CAD modeling to curing—is data-verified and tracked to ensure uniform output.

Key mechanisms include:

-

3D mold precision machining – Guarantees accurate geometry across high-volume runs.

-

Thermal and vibration curing control – Maintains internal density and structural strength.

-

Surface treatment standardization – Ensures consistent bonding and weather protection.

-

Embedded reinforcement integration – Aligns steel positioning with load-bearing calculations.

By controlling these parameters, Jingle’s OEM precast systems deliver structural parts that perform predictably under load and environmental stress.

Traditional Precast Production vs. OEM Custom Manufacturing

| Category | Traditional Precast Production | OEM Customized Precast Parts |

|---|---|---|

| Dimensional Tolerance | Manual casting variation ±3–5 mm | Precision molds ±0.5–1 mm |

| Surface Quality | Uneven finishes, air pockets | Uniform, vibration-compacted finish |

| Reinforcement Integration | Manual placement | CAD-based steel mesh positioning |

| Durability Control | Variable curing | Controlled thermal curing process |

| Project Adaptability | Fixed designs | Tailored dimensions and connections |

The OEM approach doesn’t just improve consistency—it redefines predictability in large-scale construction.

Core Advantages: Structural Value Through Customization

1. Dimensional Uniformity

Each unit fits precisely with adjacent structures, reducing on-site modification and installation time by up to 30%.

2. Long-Term Durability

OEM curing control extends the service life of structural elements under load, moisture, and temperature fluctuation.

3. Project Integration Efficiency

Precast parts are labeled, packaged, and scheduled for just-in-time delivery, optimizing installation workflows.

4. Cost Optimization

Reduced rework and standardized molds lower overall project costs while maintaining structural integrity.

5. Environmental Responsibility

Closed-loop material recycling minimizes waste and reduces CO₂ emissions during production.

Application Scenarios: From Urban Infrastructure to High-Performance Buildings

-

Bridge Deck and Pier Components – Uniform strength and finish for highway or railway systems.

-

Retaining Walls and Tunnels – Enhanced waterproofing and modular assembly for underground structures.

-

Building Façade Panels – Precision alignment ensuring architectural symmetry.

-

Drainage and Utility Systems – Durable modules designed for load-bearing under heavy traffic.

-

Renewable Energy Foundations – Corrosion-resistant bases for wind and solar installations.

These applications demonstrate how OEM customization elevates structural reliability while accelerating construction cycles.

Professional Selection Guidance: Aligning Precast Customization with Project Needs

Selecting the right OEM precast partner involves matching technical requirements with production capabilities.

| Project Type | Recommended Material Composition | Mold Type | Key Performance Focus |

|---|---|---|---|

| Highway & Bridge Systems | Reinforced concrete + corrosion inhibitor | Steel precision mold | Load-bearing & fatigue resistance |

| Commercial Buildings | Lightweight concrete + fiber reinforcement | Polyurethane flexible mold | Weight reduction & façade alignment |

| Subway / Tunnel Projects | High-density concrete + silica fume | Steel + rubber hybrid mold | Waterproofing & pressure resistance |

| Industrial Plants | Polymer concrete composite | Modular casting mold | Chemical resistance & stability |

| Public Infrastructure | Standard concrete with recycled aggregates | Reusable steel mold | Sustainability & cost control |

Expert insights:

-

Always verify mold precision certifications before production begins.

-

For large projects, request finite element analysis (FEA) reports on load distribution.

-

Prioritize suppliers offering BIM (Building Information Modeling) compatibility to ensure integration with digital construction plans.

The Future of Precast Engineering

The evolution of precast production lies in data-driven customization and sustainable precision. By combining engineering design with OEM process control, manufacturers can create structural components that are stronger, lighter, and easier to assemble.

At Jingle, our OEM precast solutions integrate advanced molding, CNC reinforcement cutting, and automated curing to ensure every part meets international construction standards.

Explore how Jingle’s customized precast components can support your next project by visiting our homepage or connecting with our technical team via the contact page.