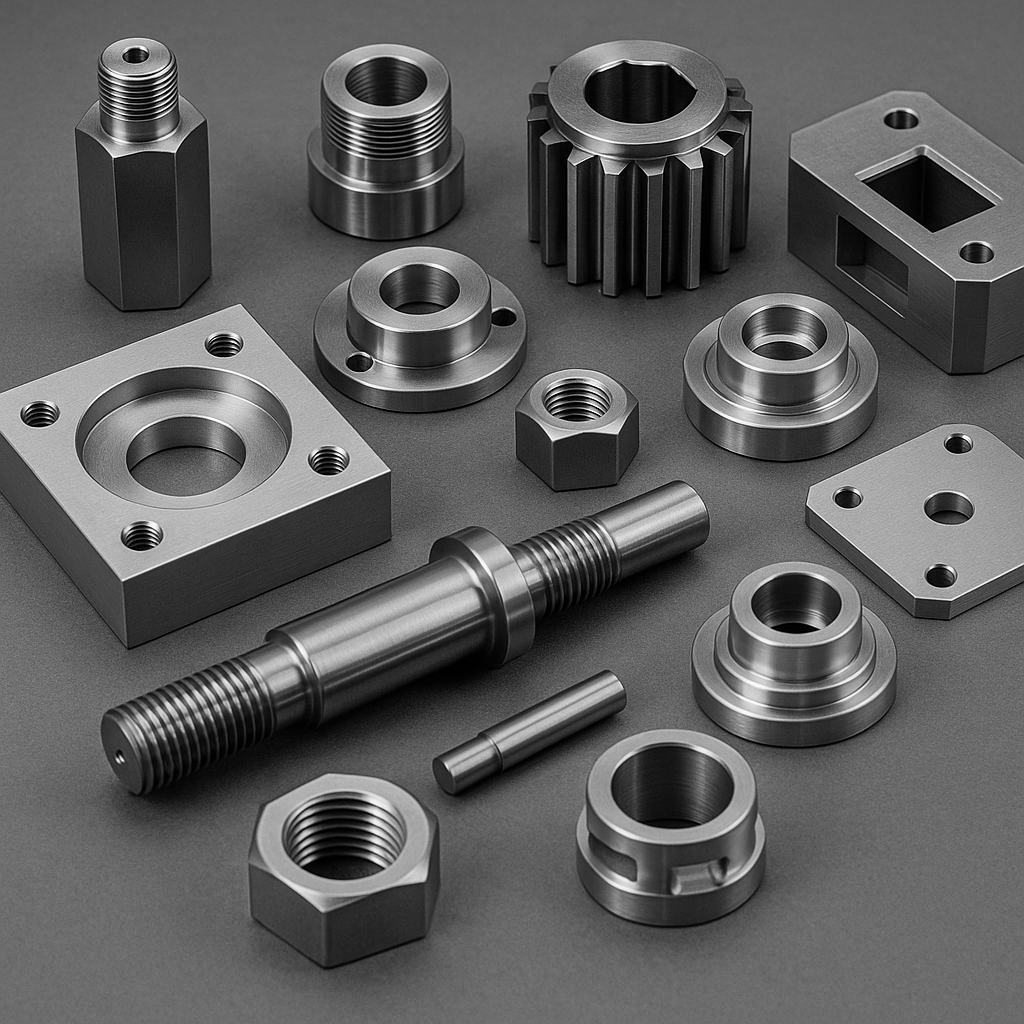

Efficiency Engineered: Wholesale Custom Industrial Components for Scalable Production

The Industrial Need for Precision at Scale

In modern manufacturing, consistency is no longer optional—it’s a strategic requirement. As supply chains expand and products become more complex, industrial buyers need components that combine high precision, repeatable quality, and flexible supply capacity. Generic hardware often fails under these expectations, leading to costly assembly delays and inconsistent product performance.

Wholesale custom industrial components address this by bridging engineering customization with large-scale manufacturing. They allow enterprises to standardize performance without sacrificing design flexibility—ensuring every shipment meets exact specifications across thousands of units.

How OEM Manufacturing Ensures Quality Consistency

Unlike traditional bulk supply, OEM-driven production emphasizes engineering control and process repeatability. Every custom industrial component is produced under data-tracked workflows and digitally verified specifications.

Key OEM production mechanisms include:

-

CAD-to-CNC integration – Guarantees design accuracy and dimensional consistency.

-

Process automation – Robotic systems manage machining, polishing, and inspection at scale.

-

Batch traceability – Each production lot is traceable back to material and process data.

-

Surface treatment standardization – Ensures uniform corrosion resistance and finish quality.

Through these processes, wholesale customization becomes not just about quantity—but about replicable quality at scale.

Standard Industrial Supply vs. Custom OEM Production

| Parameter | Standard Supply | Wholesale Custom Industrial Components |

|---|---|---|

| Design Flexibility | Limited standard catalog | Fully customized geometry & specifications |

| Dimensional Tolerance | ±0.5–1 mm | ±0.05 mm (CNC precision) |

| Quality Control | Manual inspection | Automated batch verification |

| Supply Scalability | Inconsistent batch performance | Consistent global OEM production |

| Material Options | Basic steel/aluminum | Alloy, stainless, brass, composites |

With Jingle OEM systems, quality consistency scales effortlessly—allowing manufacturers to maintain precision standards across multi-region assembly operations.

Core Advantages: How Custom Components Transform Industrial Supply

1. Precision Meets Scale

Every part is machined under calibrated systems, achieving tight tolerances across high-volume runs.

2. Cost Efficiency in Production

OEM bulk manufacturing lowers per-unit machining time by 20–30%, improving total procurement ROI.

3. Material Versatility

Supports a wide range of metals (stainless, aluminum, brass, titanium) and engineered plastics for diverse applications.

4. Streamlined Supply Chain

Direct factory-to-client logistics reduce lead times and simplify cross-border coordination.

5. Global Standard Compliance

All components meet ISO 9001, DIN, and ASTM standards—ensuring universal compatibility and import readiness.

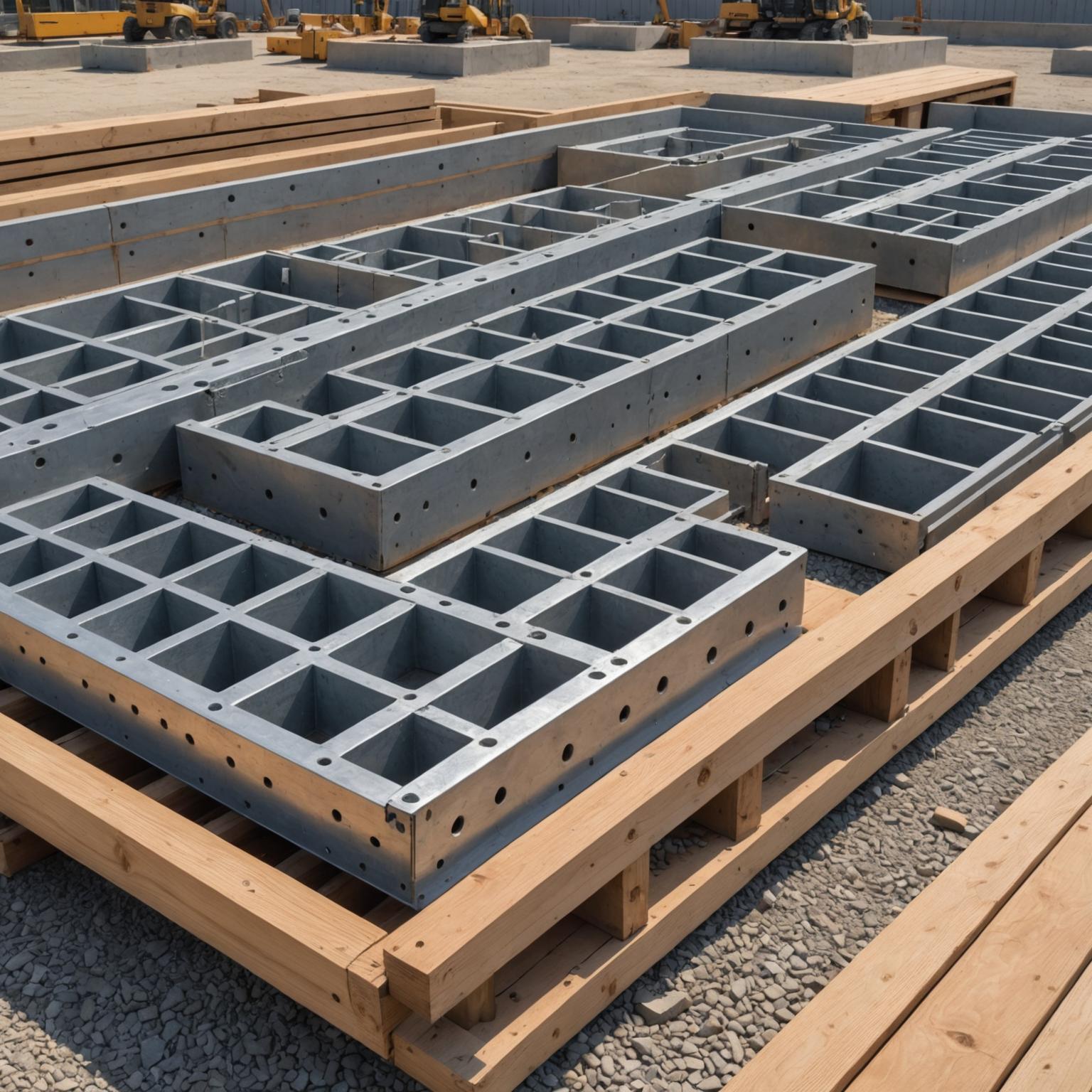

Application Scenarios: From Equipment Manufacturing to Infrastructure

-

Automotive and Transport Systems – Engine brackets, housings, and shafts optimized for vibration control.

-

Heavy Equipment Production – Reinforced joints and fasteners for sustained dynamic loading.

-

Renewable Energy Installations – Corrosion-resistant metal components for offshore and wind environments.

-

Construction Machinery – CNC structural fittings maintaining consistent strength under repeated stress.

-

Industrial Robotics – Lightweight aluminum hardware for precision motion assemblies.

Each of these cases demonstrates how wholesale customization supports both production speed and mechanical reliability—key advantages in competitive supply markets.

Professional Selection Guidance: Matching Supply Solutions to Operational Scale

Selecting the right supplier for custom industrial components requires balancing volume, precision, and logistics control. Below is a professional decision framework:

| Business Model | Recommended Production Type | Key Advantage | Typical Use Case |

|---|---|---|---|

| OEM Manufacturing Plants | Long-term batch CNC production | Consistency & low per-unit cost | Automotive, appliance manufacturing |

| Contract Assemblers | Mid-volume flexible runs | Multi-model adaptability | Industrial equipment assembly |

| Export Distributors | Standardized catalog customization | Simplified sourcing & quality assurance | Hardware trading and supply |

| Engineering Firms | Rapid prototyping + production ramp-up | Design-to-market speed | Custom machinery or tooling |

Expert Insight:

-

For global supply chains, prioritize suppliers with integrated ERP + MES systems for traceability.

-

When shipping across multiple regions, ensure surface treatments comply with REACH or RoHS standards.

-

For long-term contracts, request statistical process control (SPC) data to verify batch stability.

Turning Supply into Strategic Advantage

The future of industrial supply lies not in volume alone, but in precision that scales. Wholesale custom industrial components represent this evolution—where automation, digital inspection, and OEM-level consistency reshape global manufacturing reliability.

At Jingle, we combine CNC precision, surface treatment expertise, and data-driven quality control to deliver components that meet both engineering and logistical expectations.

To learn more about Jingle’s OEM and wholesale manufacturing capabilities, visit our homepage or contact us via the contact page for technical consultation and partnership opportunities.